5 Top Concerns of Pacific Northwest Food and Beverage Manufacturers

Since 2013, we've exhibited at Northwest Food & Beverage Expo, the main annual event of the Northwest Food Processors Association (NWFPA). A 2.5 day expo, the event addresses the urgent needs of food and beverage processors in the U.S. Pacific Northwest, mainly: Food safety education and legislation, sustainable business growth, how to strengthen branding and marketing, and equipment education. Here are a few things we learned as we talked with expo attendees.

Since 2013, we've exhibited at Northwest Food & Beverage Expo, the main annual event of the Northwest Food Processors Association (NWFPA). A 2.5 day expo, the event addresses the urgent needs of food and beverage processors in the U.S. Pacific Northwest, mainly: Food safety education and legislation, sustainable business growth, how to strengthen branding and marketing, and equipment education. Here are a few things we learned as we talked with expo attendees.

FSMA is Talk of the Town

The star of the show was discussion around changes stemming from the FDA's passage of the Food Safety Modernization Act (FSMA). Since January of 2013, the FDA has proposed seven foundational rules that comprise this piece of legislation. The purpose of the FSMA is to encourage proactivity instead of reactivity when it comes to the outbreak of foodborne illness, as well as have traceability and accountability if an outbreak should occur.

A few main areas were a focus when discussing impacts of the FSMA on food and beverage supply chains:

- Complying with sanitary transportation requirements of food products

- Effective pathogen preventative controls for low-moisture foods like cereals, nuts, snacks, and spices

- How to prevent foodborne outbreaks of Listeria

- Recordkeeping tips for proper and thorough documentation

- Evaluating and validating processes used to control contamination hazards

- How to navigate a food product recall

By and large, food and beverage manufacturers want to be ready for the changes FSMA brings, and are preparing by seeking out additional training and guidance.

Source Reduction of Food Waste

Source Reduction of Food Waste

Up to 40% of safe, viable food will never be consumed. Leading companies and non-profits are committing to the goal of halving food waste by mid-century. This will largely be accomplished by committing to source reduction or reducing the amount of food waste generated in the first place.

The Food Waste Alliance posits that when food and beverage companies become more mindful of the ultimate destination of products they create, they can not only reduce the amount of their product that ends up in landfills, but they can increase their bottom line by becoming more efficient.

Millennial Consumer Trends and Demands

Love or hate the term and all the assumptions it conveys, 'Millennials' are influencing food and beverage industries in far-reaching ways. Not often brand-loyal, this group often represents frustration for today's marketers and package designers. Just being affiliated with a certain name or image isn't enough anymore; today's products and brands have to convey a compelling story to capture the loyalty of the Millennial demographic.

Convenience and portability are other top factors that capture the attention of this consumer group. Busy young professionals in urban areas are willing to pay a premium for a product that is packaged with their needs in-mind, mainly: A light, flexible, portable, easy-to-open package that does not require tools or silverware to enjoy, and the ability to reseal the package for later enjoyment.

Benefits of Modified Atmosphere Packaging (MAP)

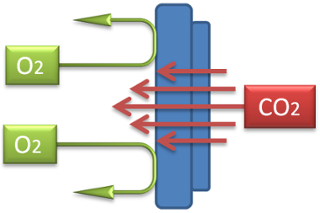

Products like coffee, produce, and raw meat are prone to oxidation and degradation from environmental factors, and as such face packaging challenges. A specific mix of gases must be maintained in the package's interior to ensure the integrity and shelf life of the product.

Products like coffee, produce, and raw meat are prone to oxidation and degradation from environmental factors, and as such face packaging challenges. A specific mix of gases must be maintained in the package's interior to ensure the integrity and shelf life of the product.

Modified Atmosphere Packaging (MAP) offers solutions to these challenged by creating or preserving an environment within a package. More and more top food and beverage companies are experiencing the benefits of MAP as they see increased shelf life for their product as well as preservation of optimal product color, texture, aroma, and taste.

Premade Pouches For the Win

The food and beverage industry has been increasingly turning away from rigid packaging containers and instead moving toward flexible packaging formats for many years. Flexible packaging has many advantages over its rigid counterpart, including increased portability and versatility, more visible marketing and branding area, and decreased use of resources to create, store, and ship.

Recently, we have noticed an uptick in interest in a specific type of flexible packaging: the premade stand-up pouch. As such, our premade pouch filling equipment has been seeing increased demand, and this was especially evident in the Pacific Northwest at NWFPA Expo.

Want to learn more about premade pouch machines? Download our new eBook for answers to 10 top questions related to this in-demand equipment.