6 Fool proof Ways Food Plants Can Increase Production Capacity

Lots of things are uncertain in business. There are many unknowns. So how can food packaging businesses and similar companies be sure they're building a thriving business model? What are some surefire ways that these companies can excel?

For many co-packers and food packaging businesses, it's all about how they can increase production capacity. Here are six ways to do this, with investments and other smart moves that will pay off over time.

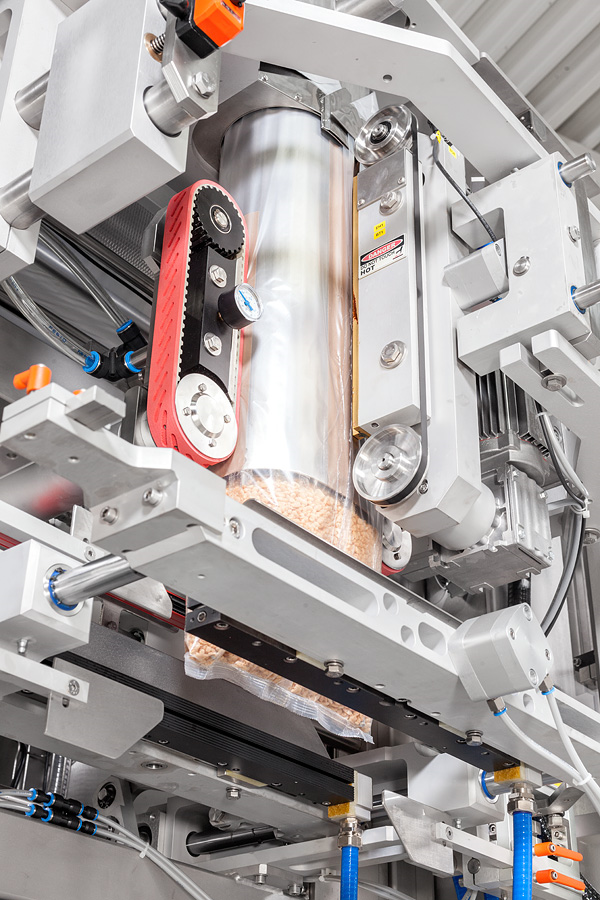

1. Get New Machines and Technology In Place

Investing in new technological assets is critical for this kind of business. New machines and equipment, as well as new operational interfaces and software, are going to pay for themselves many times over.

The new equipment will maximize production, and decrease the learning curve that's needed for onboarding new employees. New machines can allow for innovation in work processes and help companies to diversify their product line, which can mean big new revenue opportunities.

Take a look at what's available to up your game when it comes to the food packaging equipment assets used to produce results in your industry.

2. Brainstorm Process Changeover Improvements

Companies that have acquired new machines and equipment can start thinking about how to go about improving their line changes.

A big part of productivity is handling change -- decreasing that time that it takes to stop one process, readjust and recalibrate, and start cranking out another similar or different kind of product. In the industry, there's something called 'tool-free changeover', in which innovative machines do not require any extra tools to change over to different bag styles, sizes, or product types. This is another way to boost production when you really need it.

3. Make the Most of Floor Space

The best companies also know how to use their commercial property for maximum value. Instead of a random, helter-skelter setup, their workspaces, machines and benches and other items are strategically placed to allow for maximum productivity.

The best companies also know how to use their commercial property for maximum value. Instead of a random, helter-skelter setup, their workspaces, machines and benches and other items are strategically placed to allow for maximum productivity.

This doesn't mean squeezing more workstations into a smaller space. In fact, this can be terrible for productivity. Workers have to have the critical range of motion and space that they need to bring in materials or work with products. But with the right strategy, good floor space design supports better results.

4. Investigate New Distribution Methods

For some companies, distribution is a bottleneck. You might have great production inside the plant, but not enough power on the streets to get finished products where they need to be. For these companies, investing in new distribution will allow them to organically grow and expand for higher productivity and capacity over time.

5. Implement a Lean Inventory Model

Here is another way that businesses can improve productivity and enhance the bottom line for their business operations.

Lean inventory is the idea that you can use new software to precisely control your supply chain. Instead of just guessing, or keeping massive amounts of raw materials on hand, you'll know exactly when to order to get things into the plant when they're being processed. This cuts down on warehousing needs and opens up more for space for creative productivity boosting.

Lean inventory is the idea that you can use new software to precisely control your supply chain. Instead of just guessing, or keeping massive amounts of raw materials on hand, you'll know exactly when to order to get things into the plant when they're being processed. This cuts down on warehousing needs and opens up more for space for creative productivity boosting.

6. Look for Efficiency in Business Processes

Never stop looking for ways to improve a process. New software and more versatile equipment can help with this mandate. Make sure efficiency is always front and center when looking at how to implement each resource that the business uses to churn out quality products.

Increase your production capacity by leaps and bounds with packaging automation. Contact one of our packaging experts to get started today: