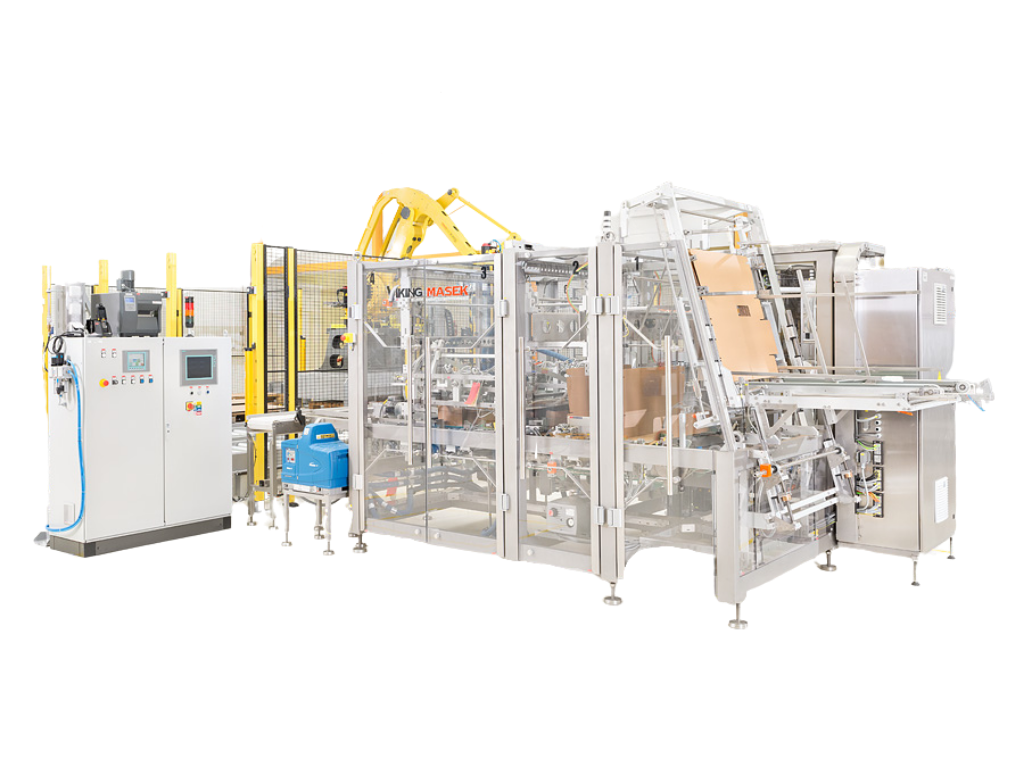

Is Your Packaging Machinery Labeled Properly?

A recent PMMI Benchmarking Report revealed that the majority of packaging machines are not adequately labeled for safety and/or operator use (Machinery Labeling - QS 2015). Most respondents (42%) reported that their machinery only comes with basic safety labels. If the original equipment manufacturer (OEM) didn’t do their due diligence, that leaves you - the end user of the machine - in a difficult position. An improperly labeled machine is a potentially dangerous machine. And when OSHA comes knocking, your machines are not going to pass inspection, leaving your company open to penalties and fines.

Safety Labels

OEMs and machine purchasers need to work together to create a safe and easy-to-operate machine. Packaging machinery should follow ANSI/PMMI B155.1-2011 Safety Requirements for Packaging Machinery and Packaging-Related Converting Machinery. Let's take a look at the specific requirements of ANSI/PMMI B155 for safety labels.

Machinery (product) safety signs and labels shall:

- conform to the requirements of ANSI Z535.4 or ISO 3864;

- be suitable for the conditions of use;

- be duplicated or appear in the manual.

“All energy isolating devices shall be adequately labeled or marked to indicate their function.”

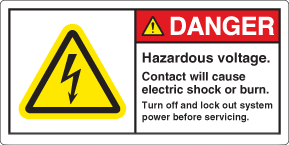

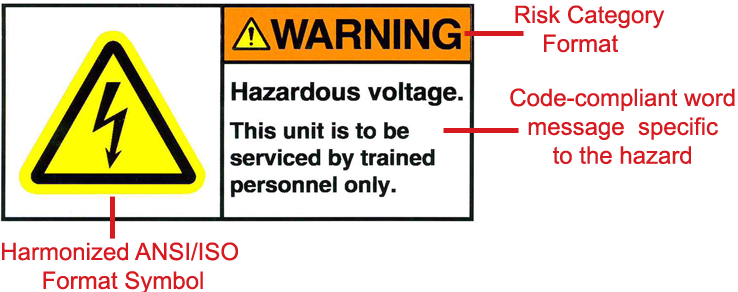

If you are going to pick one safety label standard to follow, use ANSI Z535.4. This harmonized standard satisfies OSHA, ANSI, and is also ISO compliant! In other words, your machines will be properly labeled for U.S. and international markets.

The new ANSI Z535 compliant labels are easy to identify and are more informative than ISO symbols alone. The label is made up of three parts:

- ISO/ANSI symbol

- Risk category - Caution, Warning, Danger

- Text that describes specifically what the hazard is and how to avoid it

If you are familiar with the standard ISO symbols, the ANSI Z535 labels retain the symbol but we gain additional information about the hazard. In this case, operators can easily identify that there is hazardous voltage. In addition, they are informed that only "trained personnel" may service the unit. This information saves lives!

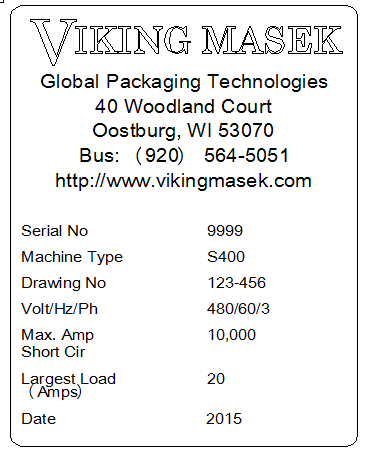

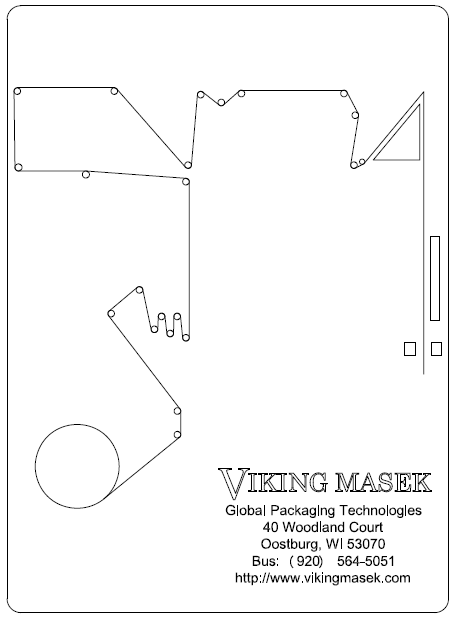

Machine Nameplates

The other required label per ANSI/PMMI B155.1-2011 is a machine nameplate.

The machinery shall have a nameplate that complies with NFPA 79 and includes:

- name and address or location of the manufacturer;

- designation of series or type;

- serial number, if any.

Notice that in addition to the required information, we also include the machine's electrical specifications. This is important because in an emergency, an electrician may not have time to call the OEM for this essential information. Plus, otherwise identical machines may have different electrical requirements depending on when they were purchased, how they were originally specced, and how they are currently being utilized (ancillary equipment like conveyors, printers, metal detectors, etc. that are wired to the main machine).

Helpful Hint Labels

Finally, in addition to just the required labels, it is always helpful to include operator instructions for things like changeovers, web-up, and routine maintenance tasks.

Proper machine labeling makes machines safer and easy-to-operate. At Viking Masek we build safety into our machines, not because we are required to by law, but because we care about every person who comes in contact with our equipment. If you ever have any concerns about the safety of your packaging equipment, please contact us for a safety audit. We are here to help.

Resources:

PMMI Research & TrendsANSI/PMMI B155.1-2011ANSI/NEMA Z535.4-2011