Wrapping Things Up: Automation as a Force Multiplier for the Manufacturing Labor Squeeze

By Robert Bur on August 1, 2025

Manufacturers across the U.S. are feeling the labor pinch. The aging workforce, high turnover rates, and increasing operational costs continue to converge and create significant disruption in growth and production. Currently, around 500,000 manufacturing positions go unfilled every month. Complicating matters is the projected need for 3.8 million new manufacturing workers by 2033 — and 1.9 million of those jobs remaining vacant.

Viking Masek Electrical Engineering Manager, Robert Bur, sat down with the Wrapping Things Up podcast crew to explore the competing priorities manufacturers face in the labor space, and how automation serves to optimize workforce capacity instead of merely replacing human hands.

Automation as a Force Multiplier

In broadest terms, Bur views automation as a force multiplier. “With automation, you can do more with less human input, and get more on the results side,” he explained. “You can increase efficiency without the pressure of replacing or expanding headcount to keep up with output.”

Automation is something that manufacturers of all sizes — from industry giants to local specialty coffee roasters — can leverage to maintain and even grow operations at scale. “You can’t just double your employee count,” Robert said. “Aside from the lack of people for the jobs, there’d be more HR resources, more managers, more infrastructure to consider. It just doesn’t scale efficiently. Automation, on the other hand, directly solves for making a lot more of a product.”

Breaking Down Misconceptions

One of the biggest myths is that automation is a “job killer” in that it fully replaces human contribution. The reality, however, is that automation creates opportunities for upskilling by taking over the repetitive tasks so workers can be reallocated to higher-value responsibilities.

Teams take on new roles such as maintenance technicians, controls engineers, and data analysts, while repetitive and injury-prone tasks are reduced or eliminated.

“Instead of a larger production staff, manufacturers might need larger warehousing, sales, and distribution staff,” Robert commented. “Maintenance-type roles expand to include technicians and electricians.”

The amount of change and training involved in integrating automation may give some manufacturers pause. Robert points out that resources are available to help. “A lot of organizations provide training for automation — the packaging equipment OEM, such as Viking Masek, local vendors or distributors of automation components, even online courses on Udemy or Coursera.”

Manufacturers are supported in navigating the human side of automated processes, but it doesn’t stop there. They also control the pace of transitioning operations to automation.

Once the decision to automate is made, there’s no need to immediately overhaul the production floor. "You can automate a single chunk and grow from there," says Robert, underscoring that flexible automation is possible for manufacturers big and small.

He suggests a natural progression. “Start with automating primary packaging, then expand upstream or downstream as needs evolve. Every challenge is solvable. Incremental automation allows teams to learn, adapt, and scale confidently.”

Viking Masek’s Difference: Expertise at Every Step

The ongoing labor shortage presents manufacturers with challenges. It also presents opportunities to maximize workforce capacity through automation. Viking Masek’s team approaches solutions not as a transaction, but a true consultative partnership. We listen carefully to understand your immediate needs and future goals, then pursue custom-engineered solutions, installation, training, and support.

Listen to the full podcast episode for more insights from Robert Bur on how automation can solve real-world challenges from labor shortages to production scaling. Subscribe to Wrapping Things Up for practical advice on automation, machinery, and more.

Related Posts

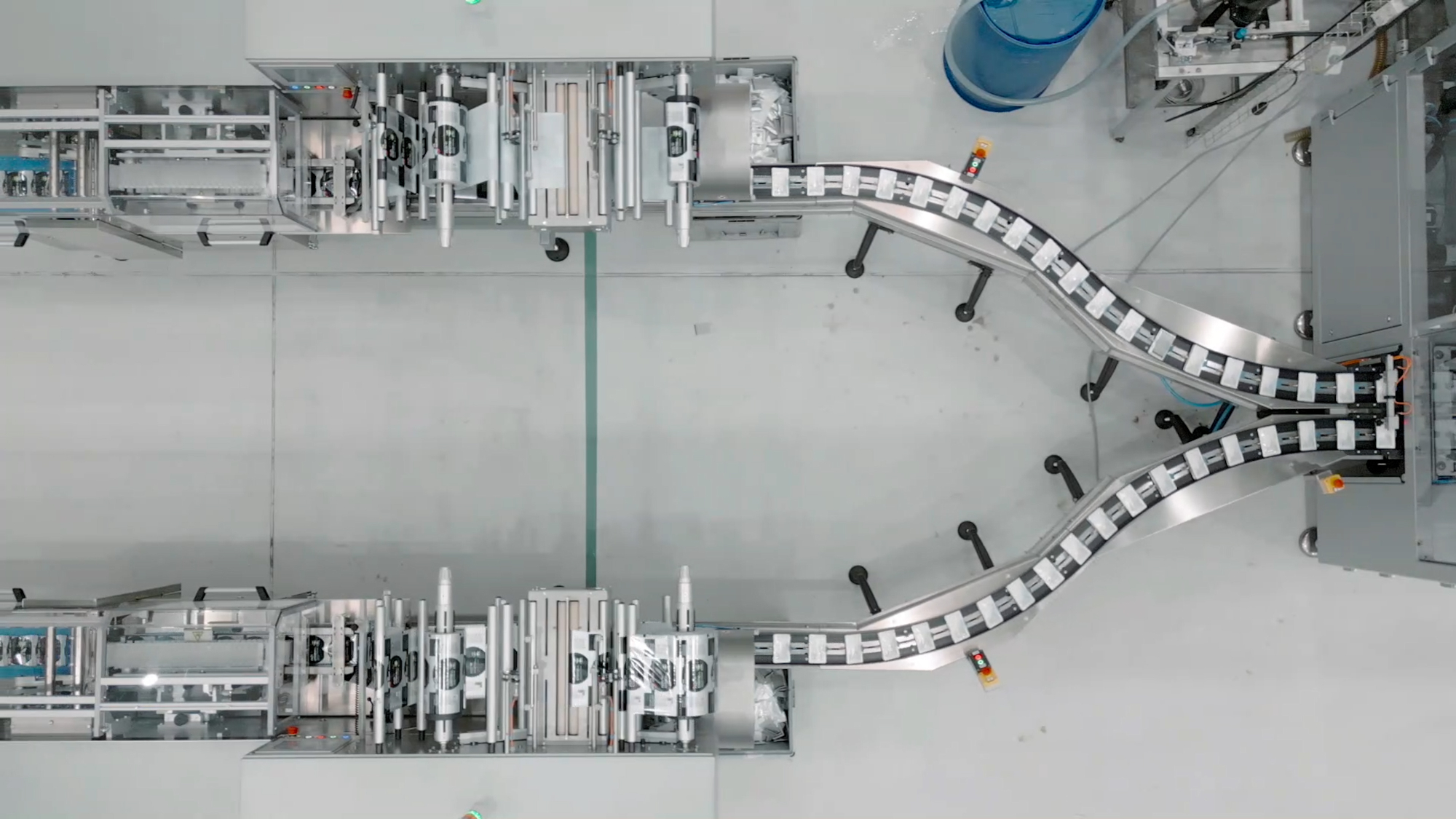

Introducing Viking Masek's advanced flow wrapping equipment

Flow Wrapping Speed, Precision & Sustainability: What Engineers Need to Know