Flow Wrapping Speed, Precision & Sustainability: What Engineers Need to Know

By Robert Barkley on January 5, 2026

In flow wrapping, chasing maximum speed can actually cost more than it saves. For packaging engineers and operations leaders in bakery, snack, and confectionery spaces, understanding the interdependency of film behavior, sealing performance, and operator practices is essential in maximizing packaging efficiency.

In this episode of Wrapping Things Up, Robert Barkley, National Sales Manager, Viking Masek Flow Wrapping Division, unpacks common flow wrapping mistakes and how to manage the factors that cause them.

Flow Wrapping Speed vs. Seal Quality: Why “Faster” Isn’t Always Better

Speeding up machines without paying attention to sealing parameters is thought to increase throughput, but it’s a trap. Quality suffers when sealing behavior isn’t accounted for, which leads to some potentially costly errors:

- Wrinkled packages

- Poor seal integrity

- Inconsistent appearance

There are also seal requirements to consider, which vary by product. Products like chocolate bars don’t require hermetic (airtight) seals, but preservative-free fresh muffins do.

“A lot of bakery customers are going after more natural-type products. They might choose to gas flush or use modified atmosphere packaging, which require very specific seals. The process isn’t as fast and limits line speed.”

– Robert Barkley, National Sales Manager, Viking Masek

The Sealing Triangle: Time, Heat & Pressure

When speed increases on the line, there’s less sealing time available. Consequently, heat and pressure must compensate, but the tradeoff has its shortfalls:

- Too much heat melts thin, and some sustainable films

- Too little time leads to weak seals

- High pressure can damage products and films

It’s a delicate balance. Depending on the product, cold seal films may be an option.

“You’re only dealing with pressure in cold seals. The goal is trying to get as much grip on the film as possible as it runs through the machine.”

Sounds simple compared to the sealing triangle, but cold sealing also has three factors to balance:

- Precise alignment

- Controlled pressure

- Optimized machine calibration

Like processes, film impacts packaging efficiency since it serves as the packaging system’s foundation. Choices can add to or detract from results.

How Film Thickness & Type Impact Flow Wrapping Efficiency

Should packaging engineers choose to swap film to maximize cost savings, the decision may unknowingly hurt packaging efficiency. Even a minor change in film thickness or substrate can introduce:

- Sealing challenges

- Drag and tension issues

- Control misalignments

Physics is also at play:

- Thin films are prone to tearing and wrinkling

- Thick films require stronger sealing force and additional drive support

“Not every flow wrapping technology can handle unique films. It’s imperative to talk to your equipment supplier to understand if and what adjustments can be made to course correct.”

The Impact of Sustainable Films

The point is reinforced as sustainable films emerge. There is no such thing as a simple film swap.

Paper-based, recyclable, and compostable films often demand:

- Tighter tolerances

- Slower speeds

- Additional machine features, such as film path support and sealing head changes

Robert cautions that for any film type, what looks good on the roll may behave differently in final form. Paper-based films, for example, can crease, stretch, or tear in unexpected ways. The hidden hazards can lull some operators into a false sense of security in making unilateral decisions about machine settings.

Preventing Downtime Caused by Operator Adjustments

Well-meaning operators often tweak speed, pressure, or sealing settings. Without understanding the potential ripple effects, those adjustments can:

- Mask deeper control or film problems

- Damage key components

- Erase calibrated settings

In short, changes can translate to costly downtime. To give operators every advantage on the line without the pressure of individual decision-making, three elements are required:

- Hands-on training

- Role-based access controls

- “Reset to factory defaults” functionality

That’s where guidance from a packaging equipment partner such as Viking Masek can help.

“Our customers depend on us to be the experts on equipment. They’re the experts on their products. When we work together to train people on the floor, everyone learns. Any tweaks can happen in real-time, and production is uninterrupted.”

The Power of the Pilot Line

In other scenarios, piloting new films holds the answer, especially when manufacturers can’t or don’t want to shut down production. Packaging engineers may opt for a pilot line or even entry-level equipment to test out films.

Running simulations before full-scale rollout often proves helpful.

“Pilot lines are slower and hand-loaded, but speed isn’t the goal. It’s really to test that film out and see how it goes. We’ve done it for multi-billion dollar brands and mom-and-pop shops alike.”

There are several paths to successful flow wrapping, but Robert sees a common denominator:

“It takes transparency and vulnerability to make sure everyone is on the same page. Equipment OEMs, customers, and film suppliers all have a piece of the puzzle. It’s when we communicate and work together that packaging solutions get figured out much quicker. Collaboration is the real differentiator.”

Get more insights from Robert Barkley by listening to the full conversation on the Wrapping Things Up podcast. You can also catch up on past episodes that cover a broad range of topics.

FAQs

1. Why does increasing flow wrapping speed reduce seal quality?

As flow wrapping speed increases, the available time for sealing decreases. This forces the system to rely more heavily on heat and pressure, which can damage delicate or sustainable films and lead to weak or inconsistent seals.

2. How do I know if my seal issues are caused by film or the machine?

Start by testing the film under controlled conditions. A small change in film thickness, stretch, or coating can affect how it runs. If your equipment was calibrated for a different film spec, even minor changes can cause issues that appear to be mechanical.

3. Can I run sustainable or paper-based films on my current flow wrapper?

Sometimes. These films often require slower speeds, tighter controls, and mechanical changes like modified sealing heads or adjusted film paths. Testing the film with your OEM before running production is strongly recommended.

Related Posts

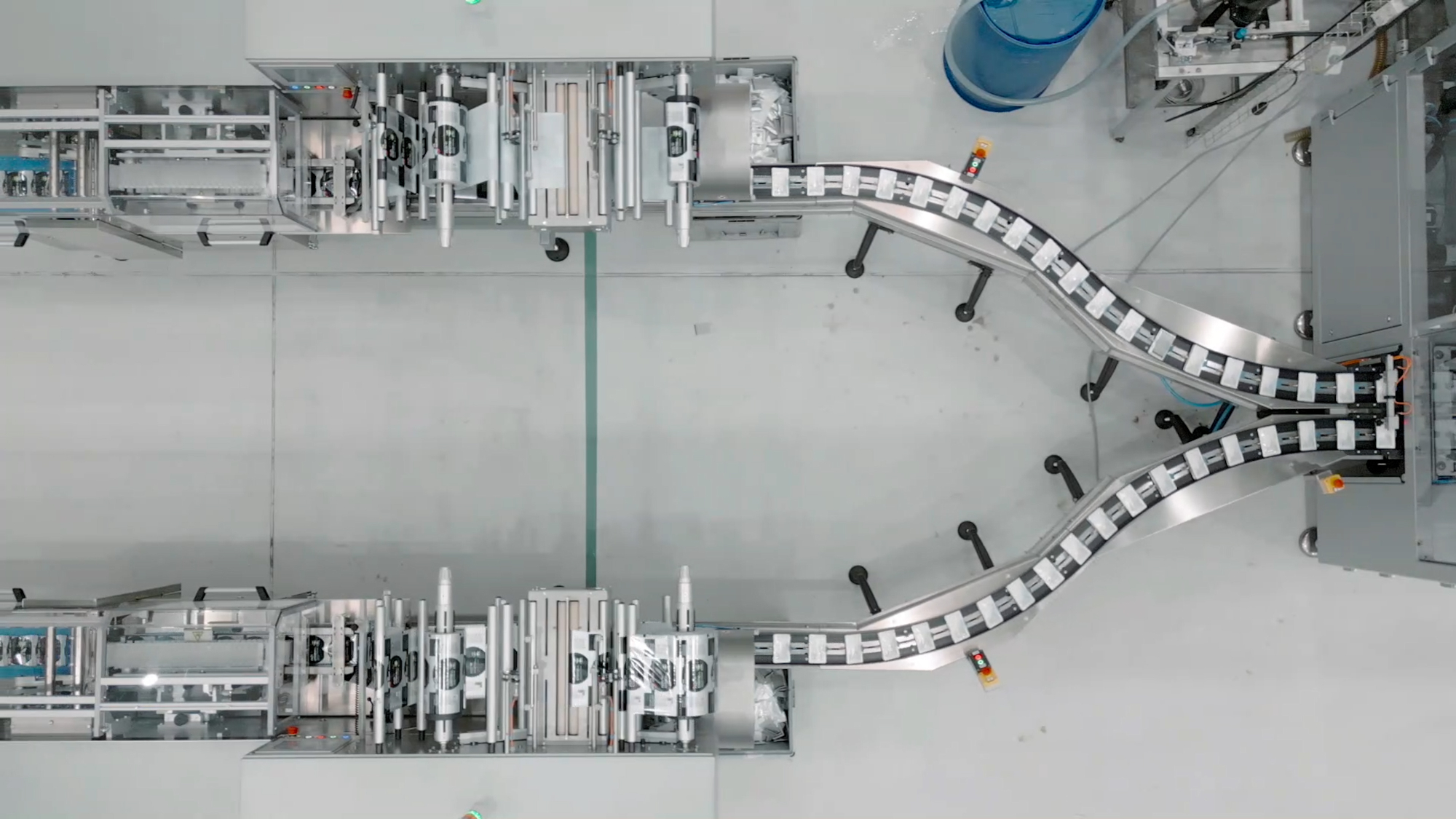

Optimizing packaging efficiency: The role of Flow Wrapping Machines in integrated systems

Introducing Viking Masek's advanced flow wrapping equipment