Change Over a Rotary Pouch Fill Machine in Under 5 Minutes

By Scott Miller on February 7, 2018

In the packaging equipment world, a changeover is adjusting a machine to accommodate different bags and/or products. Changeovers mean the machine is offline and not producing, which equals money down the drain. The easier and quicker the changeover the better, especially for companies that need to package products in a variety of different bags.

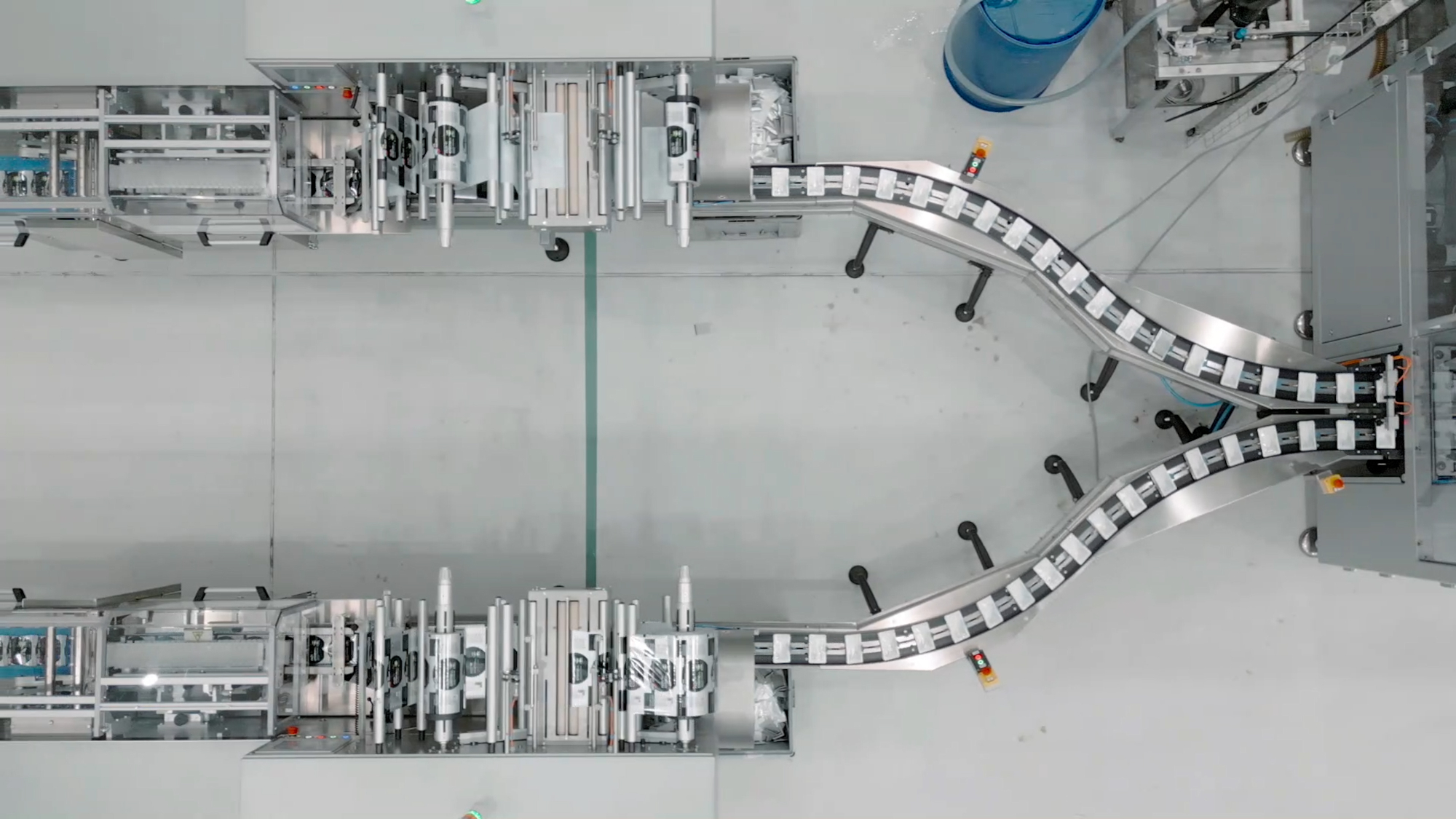

For this reason, rotary premade pouch fill and seal machines are becoming widely popular for CPG companies. Instead of requiring 30 minutes to changeover a VFFS machine or hours to changeover HFFS equipment, a modern rotary premade pouch machine takes a matter of minutes (and should take less than 5*). This means more frequent changeovers will not considerably affect machine uptime and it's no longer disadvantageous to do very short runs of 20 - 100 bags.

So put away your tools, you won't need them. Here are the simple steps required to adjust an automatic pouch machine for different bags:

Step 1: Adjust bag grippers

The machine operator changes a setting on the Human Machine Interface (HMI) that that adjusts the bag grippers to the width of the new pouches. The HMI is the ‘brain’ of the machine and usually has a modern touch-screen interface for user-friendly operation. The bag grippers do just what they say: grip the bag and hold it as it moves through the steps of the packaging system.

Bag parameters can be saved for future use. Most premade pouch fill and seal machines will have the capacity to ‘remember’ the settings for many different bag sizes.

Step 2: Adjust bag feed guides

The guides that feed the pouches into the machine need to be adjusted to accommodate the new bag width. This is done by turning the magazine guide adjustment handle either clockwise (decrease the width) or counterclockwise (increase the width). This simple adjustment requires no tools.

Step 3: Adjust bag feeding roller

Sometimes a third adjustment is necessary if the bag length differs from a previous setting. This involves moving the bag feeding roller to a new position. The bag roller is the mechanism by which bags are fed into the machine and must be moved based upon bag length. Again, this is done with the turn of a few knobs, no tools necessary.

Step 4: Test your changes

Do a test run to make sure the changeover was successful. One of the great things about premade pouch fill and seal machines is that you can run bags through the system without dispensing product, which means minimal or zero product waste during setup.

That’s it! In the time it takes to grab a cup of coffee, your rotary pouch packing machine is ready to fill and seal different bags.

*Changeover time can vary based on operator skill and other variable conditions.

Learn more about premade pouch machines

Download our free eBook that answers 10 top questions about rotary pouch filling and sealing equipment and what to look for when shopping for this machinery.

Related Posts

How to Choose the Right Packaging Automation Partner

Introducing Viking Masek's advanced flow wrapping equipment