[VIDEO DEMO] How a cannabis pre-roll packaging machine works

By Scott Miller on November 30, 2020

![<span id="hs_cos_wrapper_name" class="hs_cos_wrapper hs_cos_wrapper_meta_field hs_cos_wrapper_type_text" style="" data-hs-cos-general-type="meta_field" data-hs-cos-type="text" >[VIDEO DEMO] How a cannabis pre-roll packaging machine works</span>](https://vikingmasek.com/hubfs/Imported_Blog_Media/Viking_Masek_YouTube_Thumbnail_how_to_package_cannabis_prerolls_1.png)

Packaging automation is taking the cannabis industry by storm.

With legalization sweeping Canada in 2018 and increasing numbers of US states choosing to do the same, manufacturers of cannabis pre-rolls are now seeing the need for automated packaging lines to support their continued growth.

I'm Scott Miller, Viking Masek's VP of Product & Technology, and today I'm taking you on a video walkthrough of a complete 8S-235 pouch packing system for cannabis prerolls.

WANT THE TECHNICAL DETAILS? LEARN HOW A PREMADE POUCH MACHINE WORKS >>

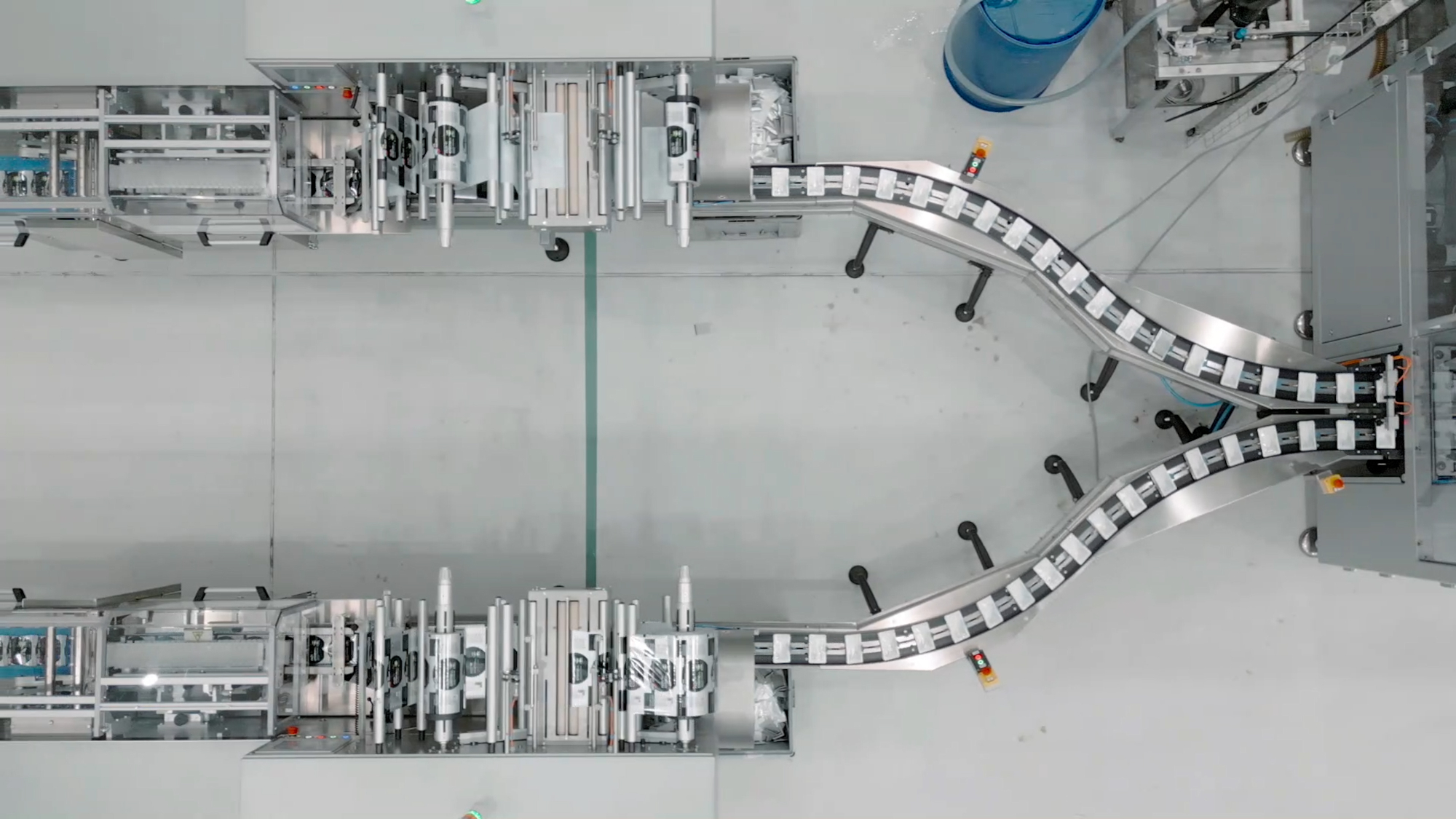

STEP 1: Convey cartons of cannabis prerolls to the packing machine

What you'll see as the demo begins is the pre-rolled joints are already packaged in cartons. At this point, we are bringing in the cartons through a bucket elevator into a vibratory feed system which will deposit the cartons into child-resistant stand-up premade pouches.

STEP 2: Open premade pouches

The pouch opening station uses vacuum suction pucks on the top and bottom of the bag to grip the pouch and open it. If at this stage the bottom and the top are not opened the machine will sense that, along with any type of reject that would come along from a camera system that detects irregularities with pouch placement. If the bag is not opened or does not pass quality control, the subsequent stations will not engage. This ensures minimal wasted product and the ability to reuse the bag in a future cycle.

STEP 3: Fill pouches with cartons of prerolls

The next step is the fill station, which dives up and down as we're filling to allow the fill funnel to penetrate the opening of the bag to ensure proper carton placement within the pouch.

STEP 4: Optional inspection

If the customer chooses to do additional quality control at this point we would immediately inspect the filled pouch with a vision inspection system. If the product is in the sealing area of the pouch or is not properly placed within the bag, the remaining stations will not engage.

STEP 5: Seal & cool premade pouches

The sealing station uses a heated seal bar to bond the top of the bags together to create a strong seam, which seals the bag closed. The heat seal station is followed by a cooling station that cools the seal, strengthening it.

STEP 6: Discharge finished pouches

As the finished pouch comes out onto the exit conveyor, it hits a 90° turn and is discharged from the machine. Based on customer specifications and available space within their facility, different conveyor configurations are available.

STEP 7: Optional downstream equipment

Downstream equipment like label applicators, carton packing equipment, or palletizing equipment can be installed to meet customer specifications.

Learn more about packaging equipment for cannabis pre-rolls

Interested in cannabis packaging machines but don't know where to start? Our experts can help. Download our free guide to getting started with cannabis packaging systems:

Related Posts

Brewing success: How Just Us Coffee automated coffee packaging to perfection

Viking Masek Doubles Down on Secondary Packaging: North American Capabilities Expansion Driven by Increased Customer Demand