Overview

Rugged, Efficient Horizontal Flow Wrappers Offer Versatile Solutions

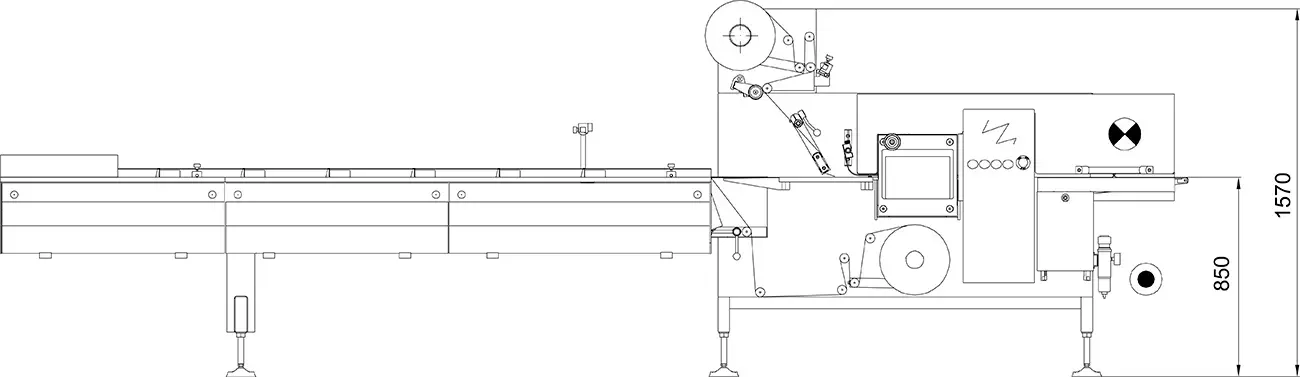

The FW-30 and FW-300 Flow Wrappers (featuring top and bottom film reel holders) are versatile horizontal packaging machines engineered for flexibility, ease of use, and low maintenance. With speeds up to 200 BPM, the FW-30 is ideal for semi-automatic feeding and frequent format changes, while the FW-300 accommodates variable production speeds and both semi- and fully-automatic feeding at up to 500 BPM. Both models are built on a shared modular platform known for its robust cantilever construction and servo-driven precision.

Key Features

- Designed for small to large products with quick format changeover

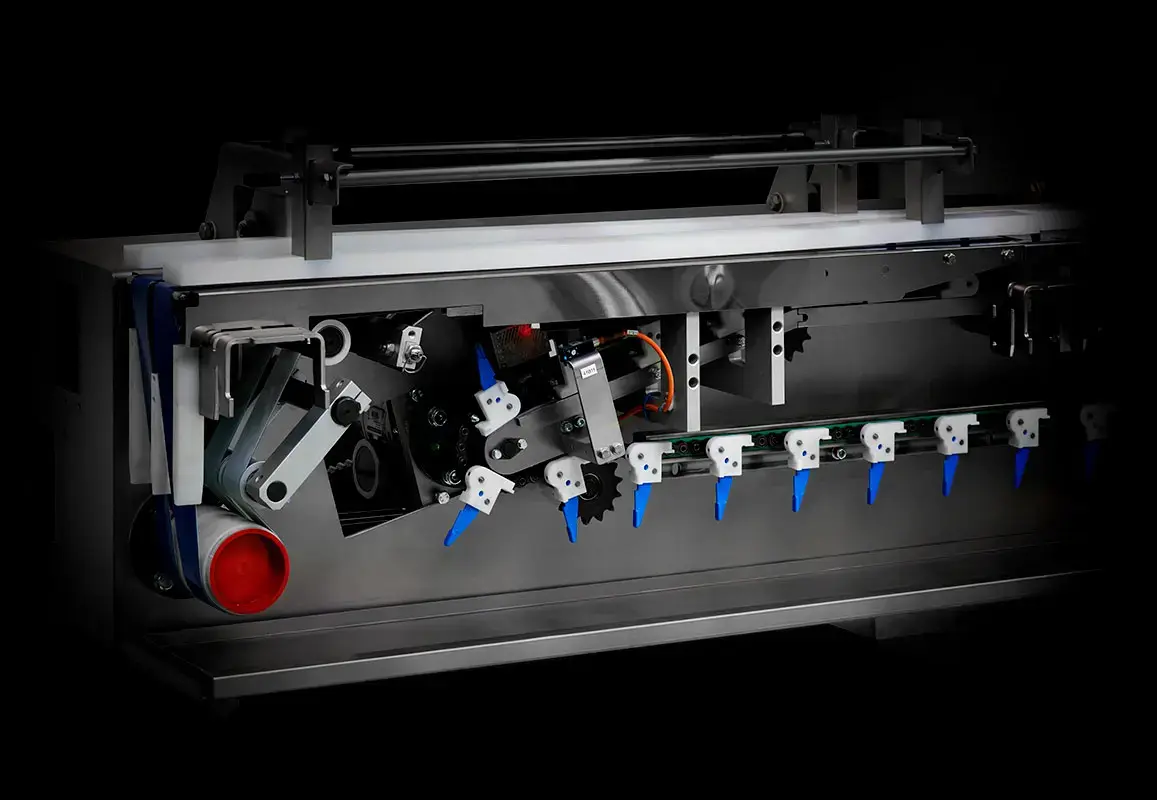

- Modular, cantilevered design ensures easy operation and hygiene

- Servo-driven controls for consistent, high-performance packaging

- Supports semi- or fully-automated feeding systems

- Compatible with a wide range of accessories and product types

- Built for demanding production environments and low maintenance

Specs PDFs

Specifications

| Safety Compliance | CE Directive 98/37/CE CE Directive 89/336 CEE - 93/68/CEE CE Directive 72/23 CEE - 93/68/CEE EN 415-3 / EN 60204-1 / EN ISO 12100-1 / EN ISO 12100-2 / EN 294 / EN 418 |

|---|---|

| Power Supply | 480V 3ph |

| Electrical Consumption | 12 - 32 amps |

| Air Consumption | 2 cfm @ 90 psi |

| Noise Level | Less than 80 db |

| Weight | Between 2,200 - 3,300 lbs |

Features

- Pusher conveyor

- Top and bottom reel holder

- Universal forming box

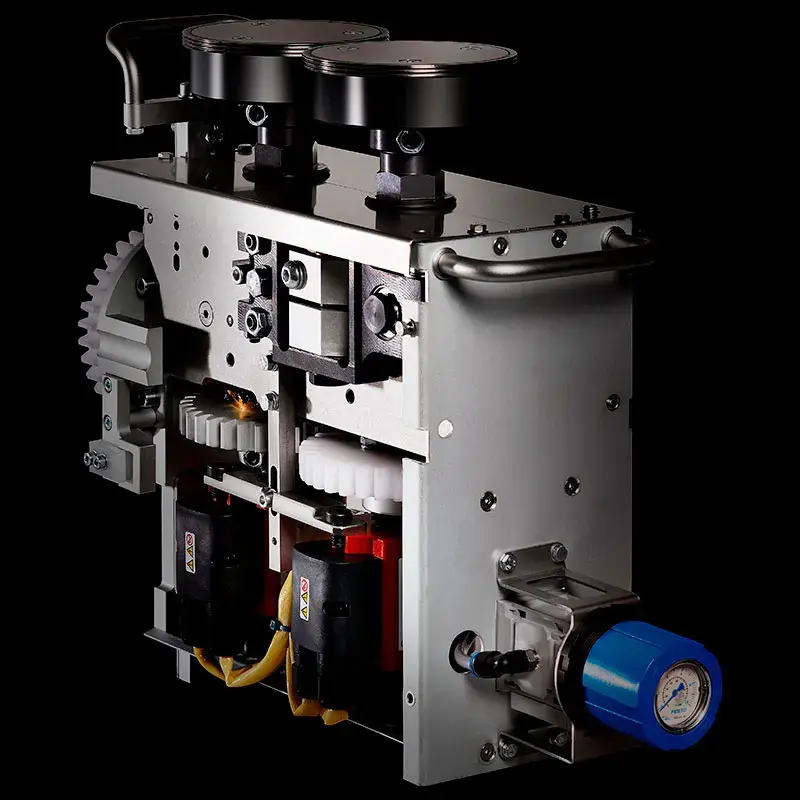

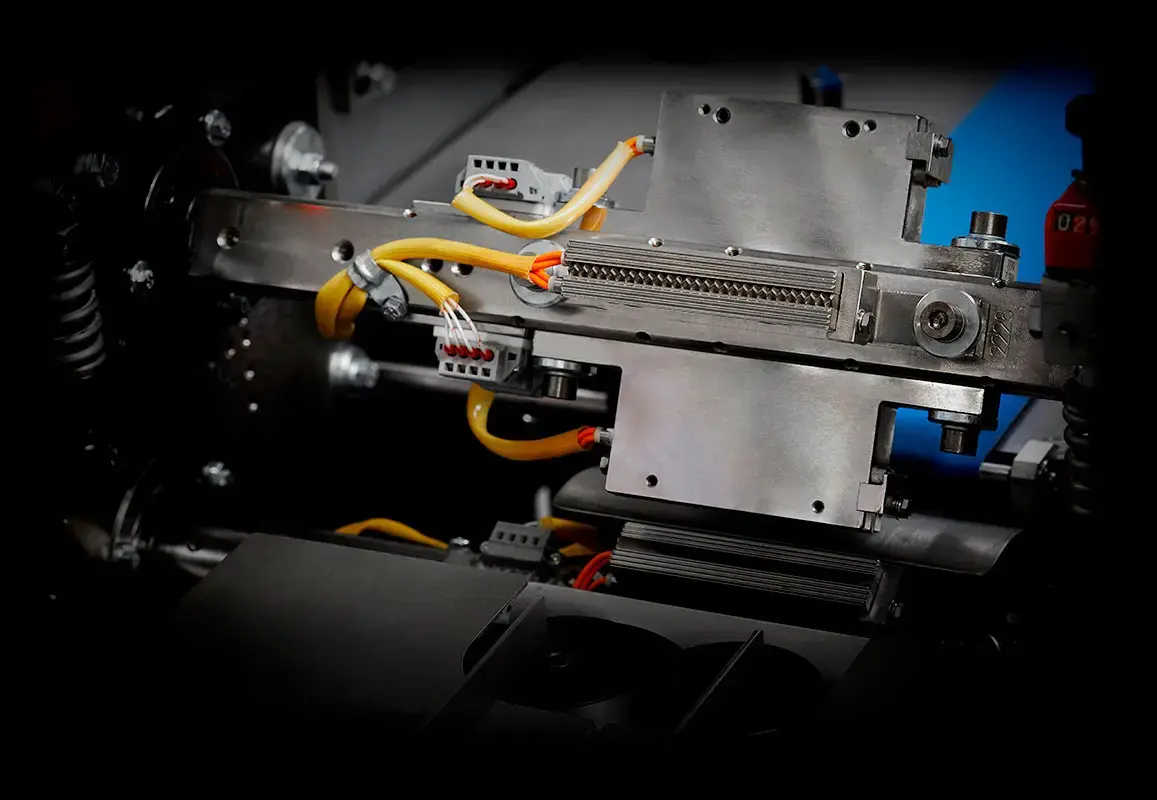

- Fin longitudinal sealing unit

- End cutting and welding unit

- Longitudinal welding module

- Outfeed conveyor with rejection

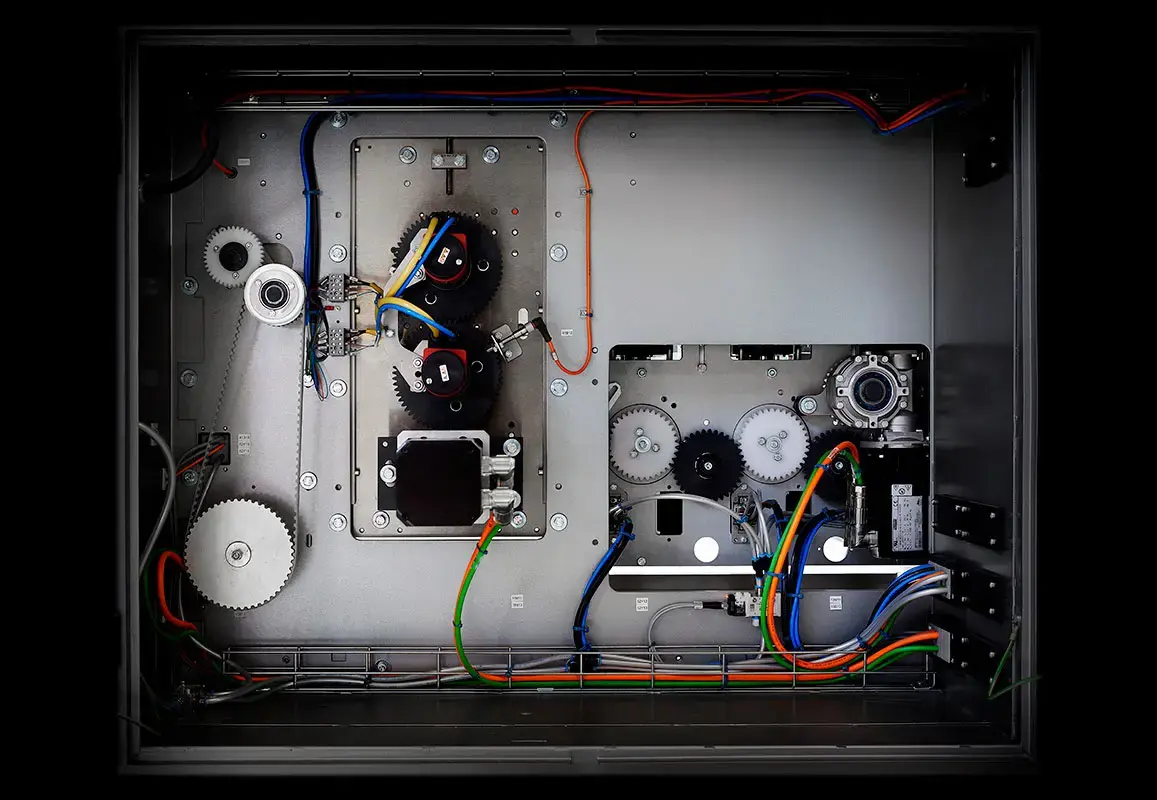

- Transmission cabinet

- Intuitive touch screen human interface (HMI)

- Easy changeover

- Modular construction

- Minimal maintenance requirements

- Poly configuration for polyethylene films

- Cold configuration for cold sealing films

- Box motion configuration for hermetic sealing

- Robust stainless steel build

- Integration with feeders

- Integration with ancillary equipment

- Allen Bradley controls

- Automatic film splice

Compatible Applications

Food & Beverage

Health & Medical

Options

- Poly configuration for polyethylene films

- Cold configuration for cold sealing films

- Box Motion configuration for hermetic sealing

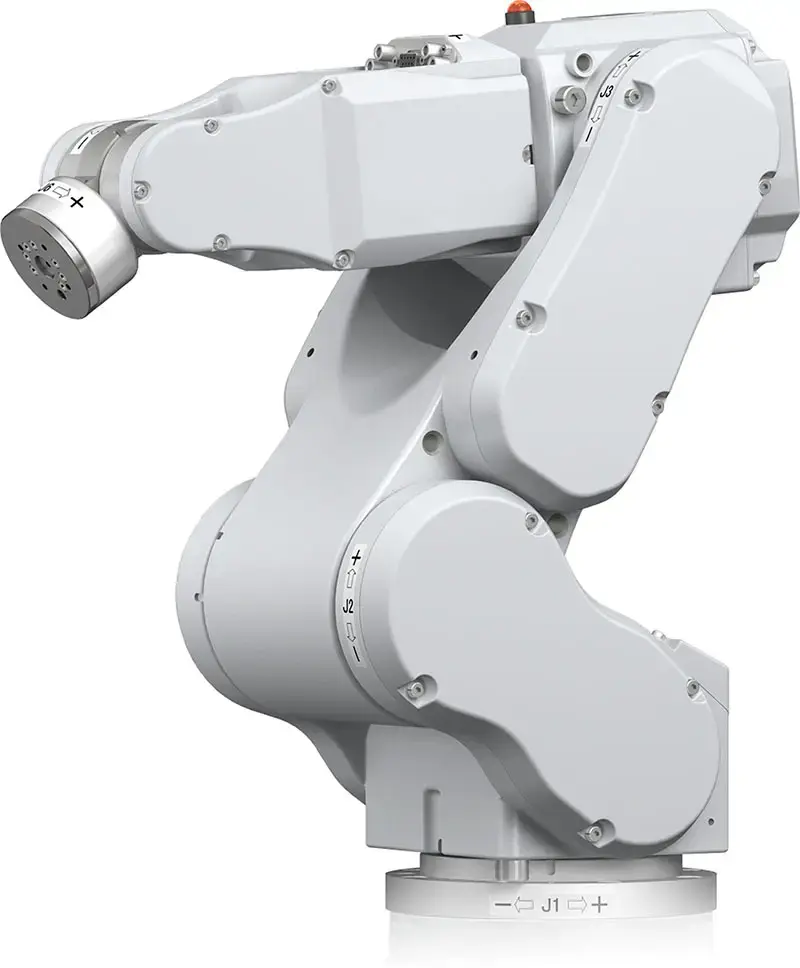

- Robotic handling for right hand execution

- Integration with feeders

- Integration with ancillary equipment

Related Machines

Let’s Talk

Exploring automation for the first time? Looking to simplify or expand a current system? Our team is here to help! No pressure — just a real-world conversation focused on what matters most to your business.