Overview

Twin Velocity: The World's Fastest Continuous Vertical VFFS Machine

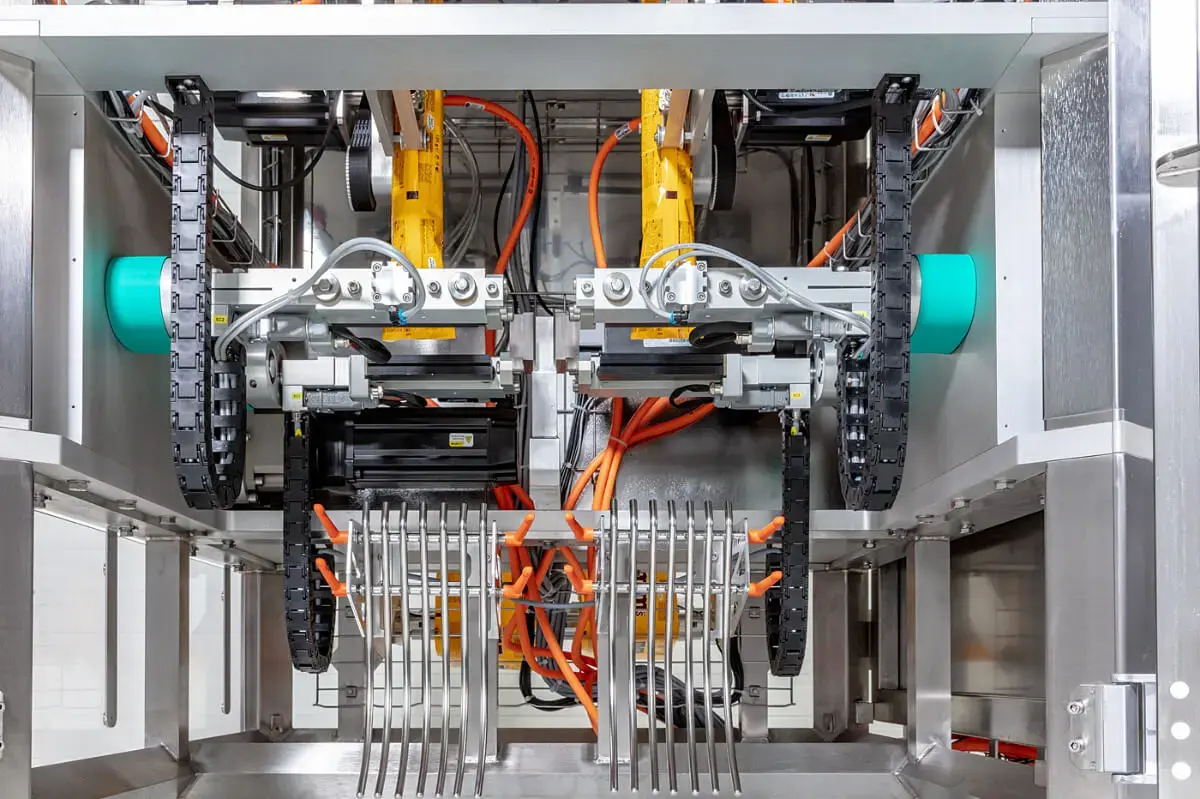

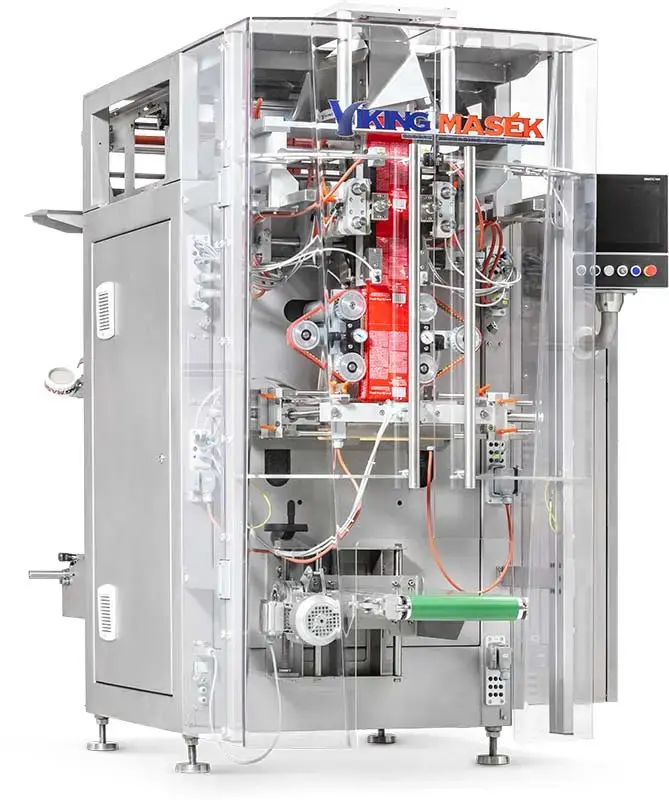

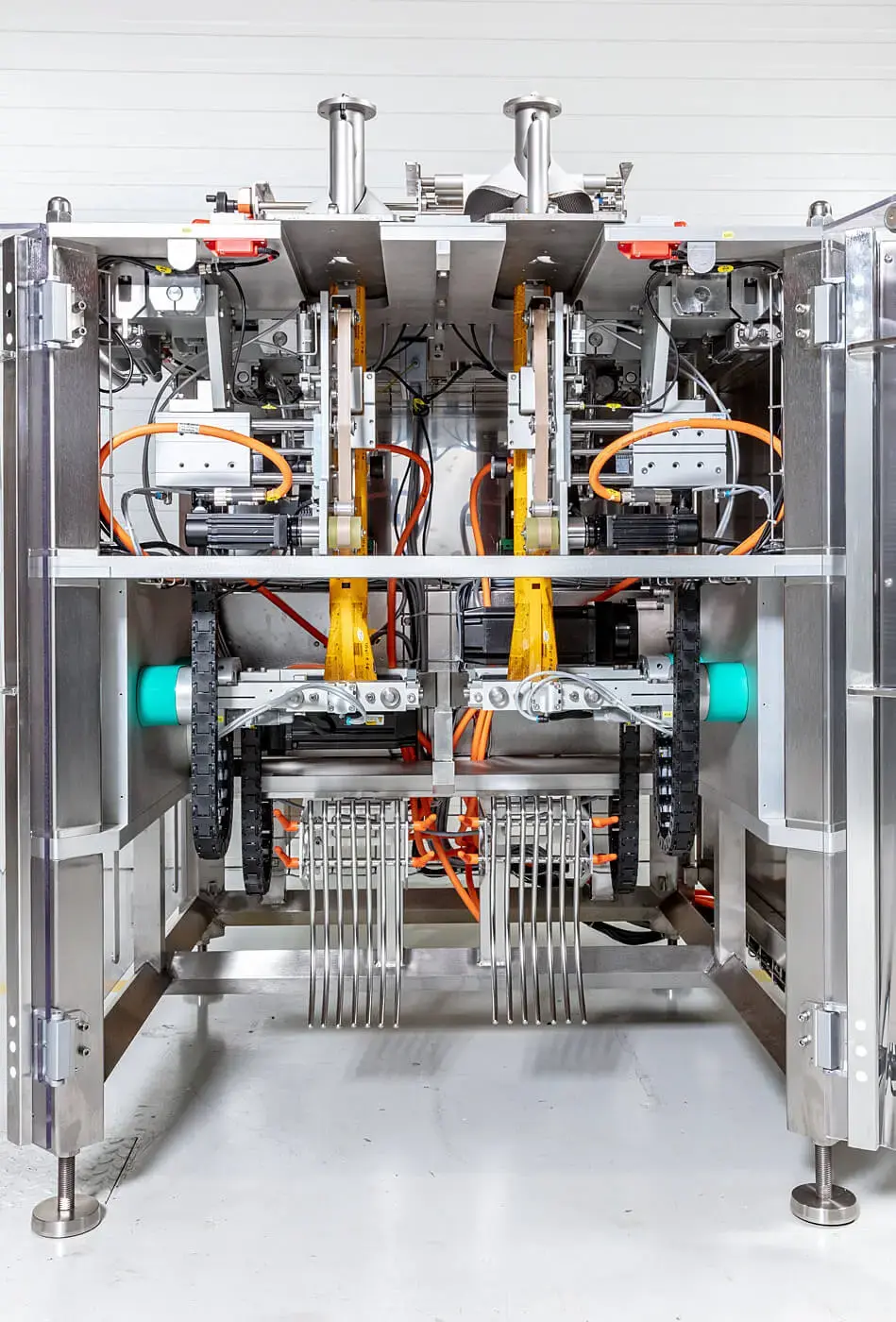

Twin Velocity is the world’s fastest continuous motion vertical VFFS machine, reaching speeds up to 540 bags per minute! Designed for ultra-high-speed packaging of dry goods like snacks, coffee, and more, it delivers smooth, vibration-free operation and exceptional reliability. With dual lanes, intuitive controls, and compact form factor, the Twin Velocity sets the standard for performance and precision in high-output packaging environments.

Key Features

- Twin-lane design delivers speeds up to 540 bpm

- Provides smooth, vibration-free operation at all speeds

- Handles bags up to 145 mm (5.71") wide

- Built for maximum throughput with minimal downtime

Specifications

| Max. speed | 540 bpm |

|---|---|

| Weight | 1520 kb (3,350 lbs) |

| Bag width | 60 - 153 mm |

| Air pressure | 6 bar (20-25 SCFM at 90 PSI) |

| Bag length | 70-250 mm |

| Power supply | 480/3/60 |

Features

- 10" high performance (HMI)

- Robust stainless steel frame

- Patented rotary motion jaw technology

- Vertical seal and tracking

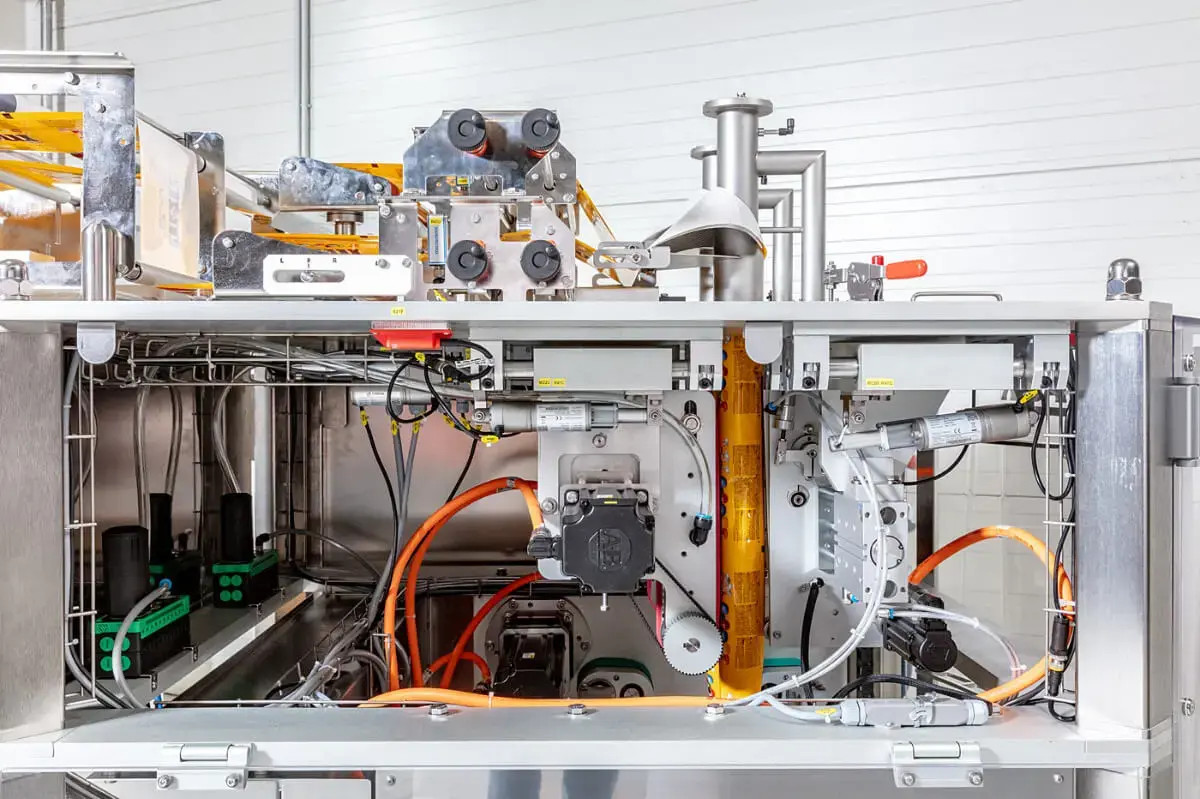

- Festo pneumatics

- Allen Bradley control system

- Servo jaw actuation

- New Teflon backseal system

- Vacuum pull belts

- Small footprint

- Short film path

- Minimal maintenance requirements

- Film unwind with tension control

- Product stagers

- Dual film roll path

- Splice detection

- Hinged electrical enclosure

- Forming tube detection

- Teflon band continuous motion vertical seal

- Bag deflators

- Photo eye for bag length controls

- Runs most film structures

- Storage for 100 product recipes

- Quick film splice table

- No tool change-over

- Off-the-shelf components

- Jaw jam detection

- Intuitive touch screen human interface (HMI)

Max Speed

540 bpm

Bag Size

Min 60 mm x 70 mm (2.36" x 2.76")

Max145 mm x 250 mm (5.71" x 9.84")

Compatible Applications

Food & Beverage

Options

- Washdown IP66 construction

- In-feed and take-away conveyors

- Gas flush

- Tear notch

- Round hole punch

- End-seal cooling air

- Static elimination

- Dual or single-lane discharge

- Integration with a variety of fillers, printers, metal detectors, label applicators, checkweighers

Let’s Talk

Exploring automation for the first time? Looking to simplify or expand a current system? Our team is here to help! No pressure — just a real-world conversation focused on what matters most to your business.