The Packaging Engineer’s Survival Guide: Adapting to a Changing Industry

By Lucas Daane on November 3, 2025

The packaging world is changing fast. Automation is advancing, labor is scarce, sustainability expectations are mounting, and packaging formats are getting more complex.

For packaging engineers, that means less time designing from scratch and more time managing projects, building business cases for automation, and ensuring operations keep running smoothly.

That’s the perspective Viking Masek’s Lucas Daane shared in Episode 5 of the Wrapping Things Up podcast. As Applications Engineering Manager, Lucas sees firsthand how engineers are evolving and the practical ways they can stay ahead.

How the Engineer’s Role Is Evolving

“In the past, customers have been designing systems for their processes on their own. They employ a lot of engineers to select and design equipment, then manufacture it themselves. We’ve seen a shift away from that in favor of focusing their efforts on the actual products.”

– Lucas Daane, Applications Engineering Manager

This shift dictates how engineers need to expand their thinking and skills.

“Being able to manage the scope of what you’re trying to accomplish and relay that information to a systems integrator that’s going to provide, install, train on, and maintain the equipment is really important.”

Three critical skills for engineers to develop include:

1. Project management: Defining scope, coordinating vendors.

2. Data-driven decision-making: Identifying downtime, defects, or labor inefficiencies.

3. Cross-functional communication: Translating technical issues into business outcomes.

Balancing Humans and Technology

Industry 4.0 focused on automation and data. Industry 5.0 adds humans back into the equation.

“Industry 5.0 is digging into how we coexist with all of this automation.”

Key results from the humans-technology balance are impactful:

- Improved user experience: Technology is designed to work with people, not replace them

- Talent reallocation: Technology frees humans from repetitive tasks to focus on other initiatives

- Safer collaboration: Cobots reduce injury risk while improving throughput

- Increased efficiency and uptime: Automation fills labor gaps

The 3 Biggest Disruptors Engineers Can’t Ignore

The pace of change in packaging isn’t just about technology. It’s also about the pressures shaping how systems are designed and run.

According to Lucas, three forces stand out as the biggest disruptors packaging engineers need to address:

1. Labor shortages: The most urgent disruptor; lack of reliable staffing leads to downtime, making automation essential.

2. Unique packaging formats: Increase engineering complexity; brands want differentiation on shelves, but it creates new system challenges.

3. Sustainability demands: Push for recyclable and reusable packaging materials changes system requirements and processes.

Engineers as Automation Influencers

Executives approve budgets, but engineers often shape automation decisions by presenting the data that frames problems, solutions, and ROI.

But moving too quickly could undermine the benefits of automation. Lucas cautions that engineers need to avoid these all-too-common pitfalls:

- Unclear scope often leads to spiraling costs

- Missing plant drawings may open the door to having insufficient space for equipment

- Utility gaps could fail to support equipment: no power, air, infrastructure, etc.

- Flexibility overload in trying to solve every problem with one system reduces effectiveness

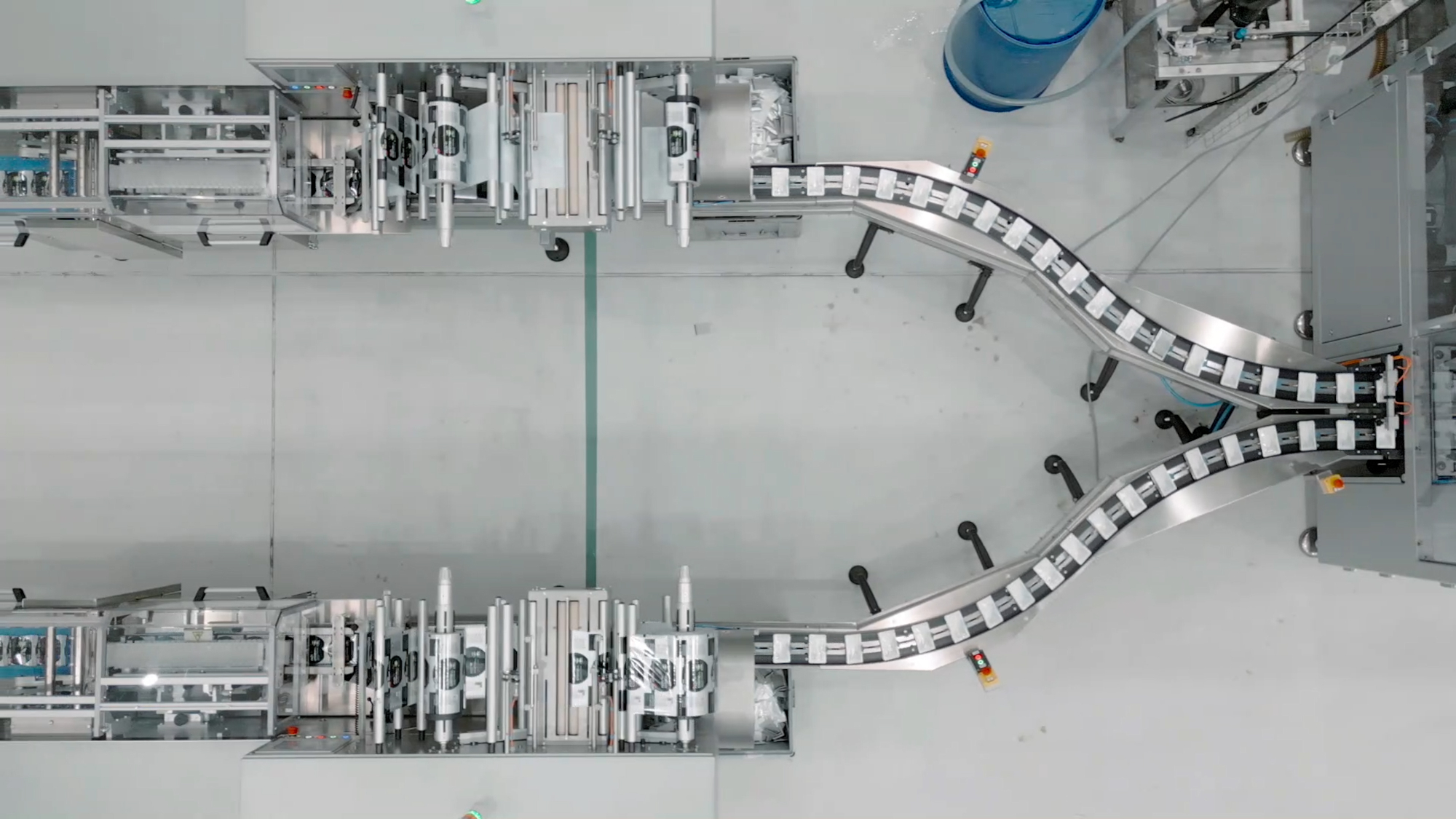

Why Turnkey Systems Are Gaining Ground

For many manufacturers, piecing equipment together from multiple vendors creates complexity and risk. That’s why more teams are implementing turnkey systems — complete, integrated solutions managed by a single partner.

Lucas finds this approach provides several benefits to engineers and customers:

- Lower project risk: Fewer transitions for engineers to manage

- Simplified accountability: One provider owns integration and troubleshooting

- More consistency: Better equipment fit, balanced processes, smoother operations

- Future-readiness: Turnkey systems scale more reliably as automation expands

Turnkey systems don’t replace engineering expertise but free it up. Instead of troubleshooting integrations, engineers can focus on strategy, ROI, and leading the next phase of packaging innovation.

Looking Ahead: Packaging Innovation

Innovation in packaging presents new challenges and new opportunities for engineers. Lucas pointed to how brands are rethinking pouches, spouts, and refillables in creative ways:

- Stand-cap and corner spout pouches for everyday items like sour cream, peanut butter, and guacamole

- Convenience-first ideas like pre-mixed pancake batter in a corner spout pouch: just unscrew the top and pour it into the pan

- Refillable formats for products like deodorant, designed to reduce single-use plastics

These innovations aren’t just marketing wins; they align with sustainability goals, eliminate unnecessary waste, and create a more convenient consumer experience. For engineers, that means designing systems that can handle new formats without sacrificing efficiency.

“What I love about automation is how it lets engineers flex their creative muscle. We can step into the role of advocate…not just solving problems, but making the case for innovative solutions that improve quality, uptime, and the overall process.”

6 Survival Strategies for Packaging Engineers

Ultimately, packaging engineers who thrive in the industry are the ones who adapt their role and expand their toolkit. Lucas shared a few survival strategies worth bookmarking:

1. Own the project, not just the design. Strong project management keeps scope creep in check and ensures smoother, collaborative vendor hand-offs.

2. Let data do the talking. ROI cases, downtime analysis, and throughput metrics give engineers the tangible influence to move automation decisions forward.

3. Balance human + tech. Cobots and smarter systems work best when engineers ensure technology complements — not replaces — people.

4. Spot the pitfalls early. Outdated plant drawings, unclear utilities, or asking systems to do “everything” can derail even the best automation plan.

5. Think turnkey when risk is high. Integrated solutions mean fewer surprises and more consistent performance.

6. Keep an eye on innovation. From refillables to spouted pouches, creative formats are reshaping what packaging lines must deliver.

Want more insights?

Listen to the full conversation with Lucas Daane on the Wrapping Things Up podcast, and catch up on past episodes that cover a broad range of topics.

FAQ: Packaging Engineers and Industry Change

How is the role of packaging engineers changing?

Packaging engineers are shifting away from in-house system design toward project management, vendor collaboration, and data-driven decision-making. Instead of building every component, engineers now focus on scope definition, ROI analysis, and ensuring packaging lines run smoothly with integrators.

How can engineers make a stronger case for automation?

Engineers can influence decision-makers by presenting clear process data — such as downtime, throughput, and quality issues — and framing automation as the solution. Starting with the “what” (problem) before the “how” (solution) makes ROI easier to demonstrate.

What skills should packaging engineers develop to stay relevant?

Key skills include project management, Six Sigma and data analysis, cross-functional communication, and emerging tools like augmented reality for training and troubleshooting.

Related Posts

Introducing Viking Masek's advanced flow wrapping equipment

How Packaging, Automation, and Supply Chains Advance Humanitarian Aid