What is coefficient of friction (COF), and why is it important in packaging?

By Danielle Ohl on June 2, 2020

Friction. An invisible force that affects...well, everything.

It's especially important to be aware of friction forces when working with form fill seal packaging equipment, and especially when choosing packaging film to run on this machinery.

More specifically, it's critical to understand a packaging film's coefficient of friction (COF). Why? It can literally make or break the performance of your packaging line, which translates to more (or less) money in your pocket. Read on:

What is coefficient of friction?

We promise we won't get too in the weeds here...after all, we're packaging machine experts, not physicists. So we consulted with some COF experts.

According to the Newnes Engineering and Physical Science Pocket Book, coefficient of friction is the amount of friction existing between two surfaces. A low value of coefficient of friction means less force is required for sliding to occur. A higher value means more force is required. COF will be different depending on the materials that are interacting with each other.

For all you math lovers out there, here's the coefficient of friction formula:

μ = f÷N

Where μ is the coefficient of friction, f is the force of friction, and N is the normal force.

Coefficient of friction is broken down into two categories: Static and Kinetic. Here's the difference:

- Static COF is a measure of the force required to begin movement. In the packaging industry, static coefficient of friction is generally used to measure the friction between bags when they are stacked or cartoned (plastic on plastic).

- Kinetic COF is a measure of the force required to maintain movement. In the packaging industry, kinetic coefficient of friction is generally used for rolls of plastic films processed on form fill seal packaging machines (plastic on metal).

How do you measure coefficient of friction?

Coefficient of friction is usually measured using a friction testing device. Basically, the plastic packaging film is dragged across a stainless steel surface and the force required to move the film is measured. The person doing the testing then does some mathematical calculations to arrive at the coefficient of friction. The resulting number will range from 0 to 1.

Why is COF important in packaging?

So what does COF have to do with automated packaging lines? A lot. More specifically for form fill seal machines, packaging film COF refers to the level of 'slip' that the packaging material has when interacting with different parts of the machine.

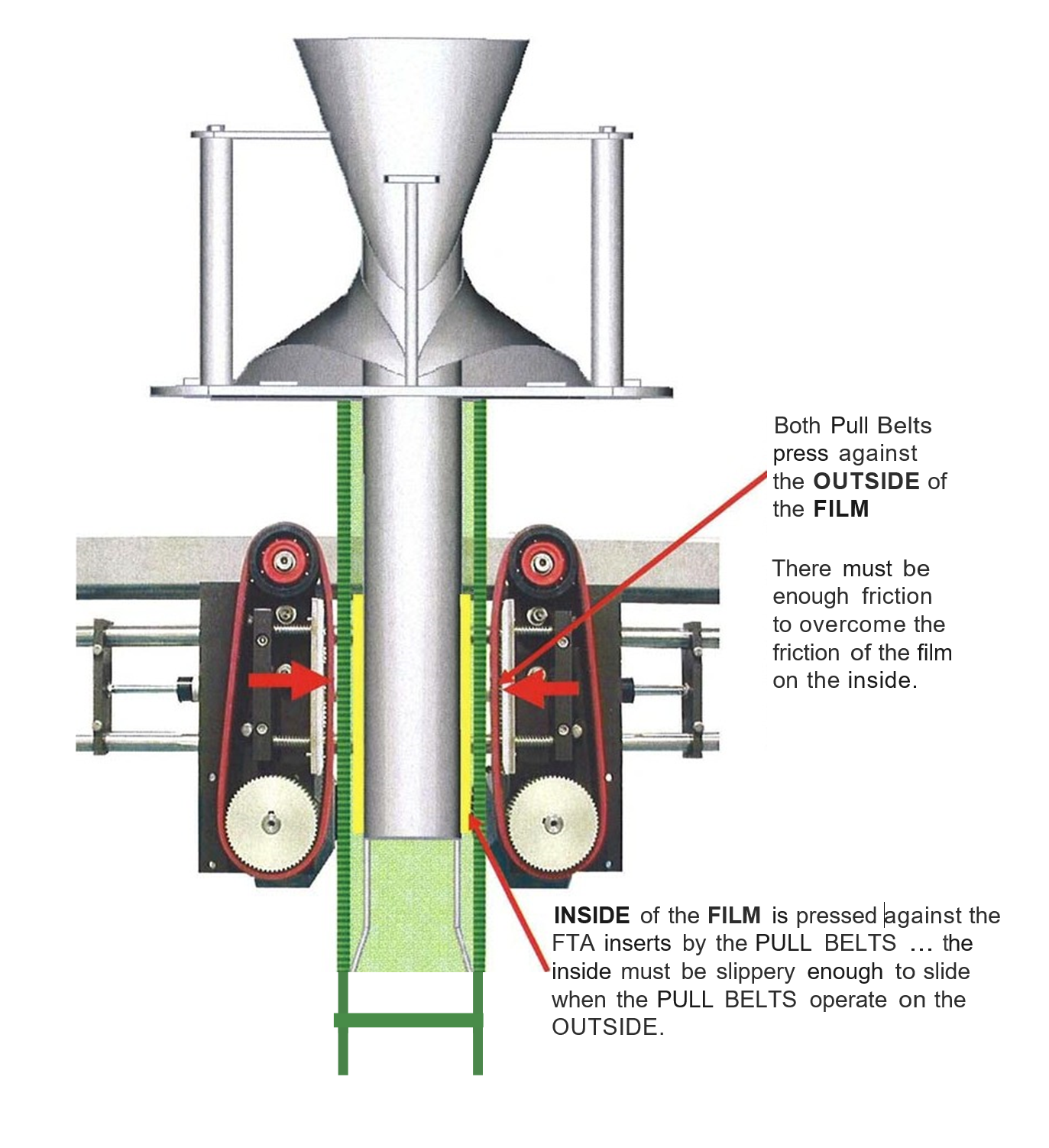

For vertical form fill seal machines in particular, packaging film interacts with a machine component called pull belts. The pull belts press against the outside of the film, sandwiching it between the belts and the forming tube, helping to draw it through the packaging system. To optimize performance, there must be enough friction on the outside of the film to overcome the friction on the inside. In other words, the inside of the film must be 'slippery' enough to be able to slide over the forming tube assembly (FTA) when the pull belts draw the film through the machine. The image below illustrates this concept:

What is the ideal range for VFFS film coefficient of friction?

The packaging material processed through a vertical form fill seal (VFFS) machine must be within an ideal range for COF in order to be compatible with the machinery. Below are industry-accepted ranges for ideal coefficient of friction values:

Inside COF: 0.200 – 0.300

Outside COF: 0.300 – 0.400

‘Perfect film’ will have a COF difference of 0.100 from inside to outside, with the outside being the higher number. However, film suppliers indicate that ‘perfect film’ is nearly impossible to achieve in practice. The most important thing is to make sure your film is always more slippery on the inside than the outside.

What happens if inside COF is higher than outside?

In short, this is bad. When inside coefficient of friction is higher than outside, a number of VFFS machine malfunctions can occur, including:

- Pull belt slippage

- Excessive pull belt wear

- Reduction in packaging speed

- Poor film web tension

- Inconsistent package dimensions

- Film tracking problems

- Seal problems (leakers)

- Film registration problems

- 'Squealing' noises when the machine is in motion

To put it simply, if the packaging film's inside COF is higher than outside COF, your VFFS machine may not be able to run consistently and efficiently, if at all.

Reduce the risk of VFFS film issues

Many VFFS machine issues, including packaging film mismatch, can be proactively minimized with proper planning from the very beginning. When it's time to source a new VFFS packaigng machine, nail down all vital specifications first with our project planning worksheet:

Get your FREE project planner >>Related Posts

Top this: How Domino’s packages its toppings 60% faster

Optimizing packaging efficiency: The role of Flow Wrapping Machines in integrated systems