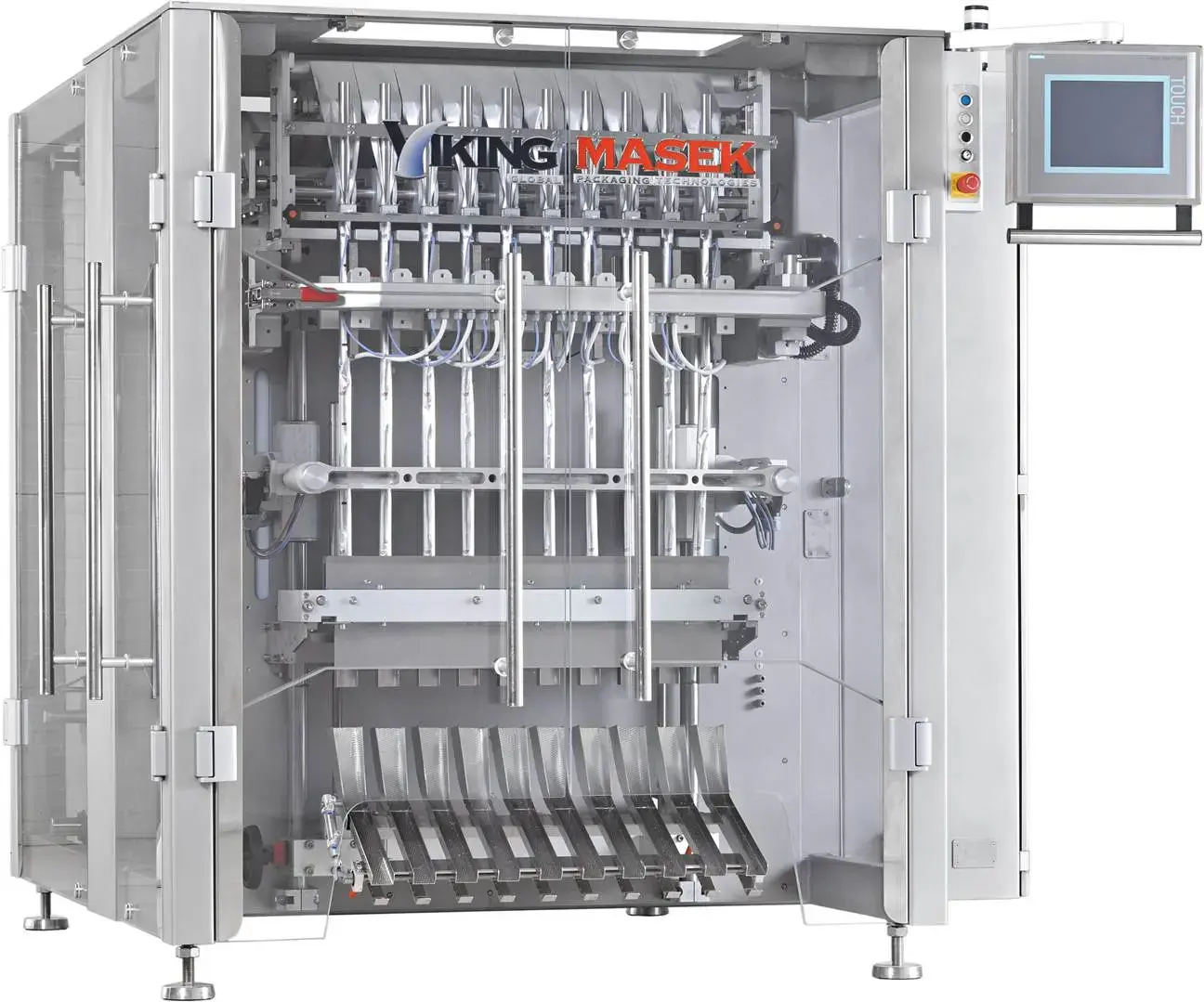

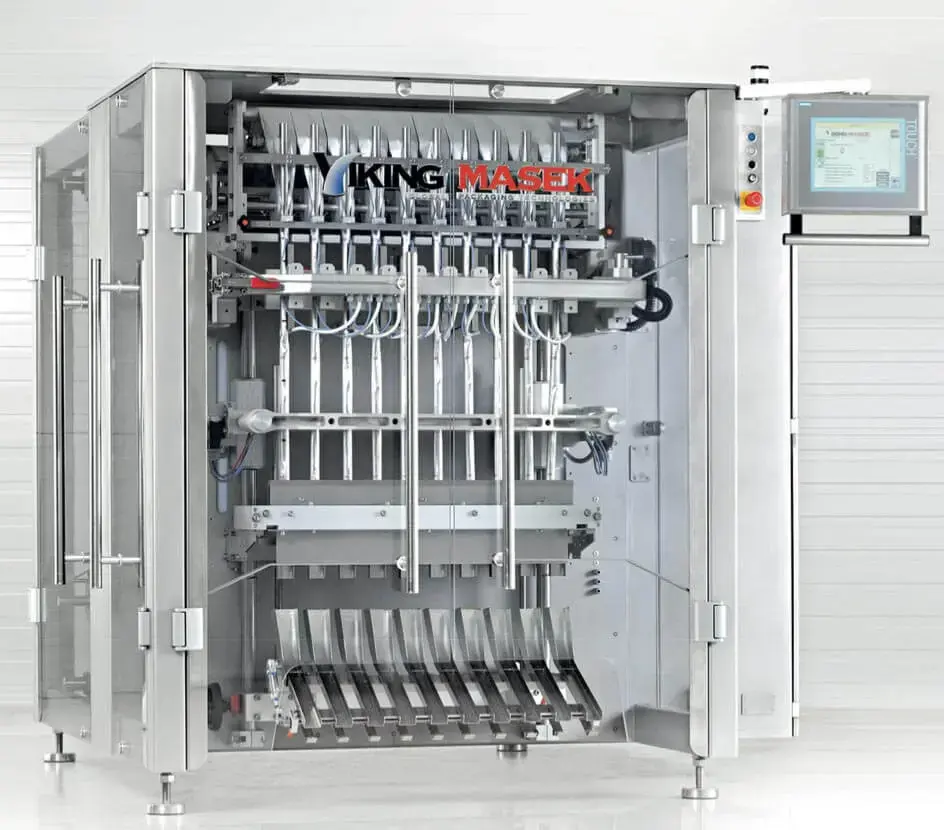

Overview

IQ/OQ Compliant Packaging for Pharma, Nutraceuticals, and CBD Products

Engineered for IQ/OQ compliance, the ST800 multi lane stick pack machine is the ideal solution for high-volume packaging of liquid or powdered pharmaceuticals, nutraceuticals, cannabis, and CBD products. With the ability to run 2 to 20 lanes, it delivers flexibility and precision for a wide range of applications and stick pack shapes.

Key Features

- IQ/OQ compliant for regulated industries

- Handles 2–20 lanes for large-scale production

- Supports both liquid and powder product types

- Customizable pouch formats: pour spouts, tear notches, easy-open features

- Available with fully automated cartoning solutions

Specifications

| Maximum Roll Diameter | 450 mm (17.75") |

|---|---|

| Maximum Roll Width | 800 mm (31.49") |

| Weight | 1,200 kg (2,650 lbs) |

| Air Pressure | 6 bar (30 CFM at 90 PSI) |

| Power Supply | 6.5 kVA (480V, three phase, 60 Hz., 20 AMPS) |

Features

- Powered film unwind with film tension control

- Film slitters and forming tubes - set per bag size

- Discharge chute

- Siemens or Allen Bradley control system

- Automatic film tracking

- Integrated inner light

- GMP construction

- Easy change-over

- Intuitive touch screen human interface (HMI)

Max Speed

80 cpm

Bag Size

Min 17 mm x 40 mm (0.67" x 1.57")

Max80 mm x 200 mm (3.15" x 7.88")

Compatible Applications

Health & Medical

Options

- Straight cut

- Zigzag cut

- Round cut

- Multi-lane volumetric filler, servo auger filler or servo liquid fillers

- Easy change-over parts and stainless storage cart

- Easy open features like tear notch or microperforation

- Various seal patterns and shapes

- Offset back seal

- Automatic stick pack length adjustment

- Individual discharge chutes

- Empty stick detection

- Empty stick rejection

- Dust suction nozzles

- Static elimination

- Film edge trimming and suction

- Embossing in the longitudinal seal

- Stainless steel construction

- Pharma construction (IQ/OQ)

- Robotic pick-and-place unit and automatic cartoning solutions

- Hot stamp, inkjet, or thermal transfer printer

- Infeed and outfeed conveyors

Let’s Talk

Exploring automation for the first time? Looking to simplify or expand a current system? Our team is here to help! No pressure — just a real-world conversation focused on what matters most to your business.