Overview

The Highest Throughput of All Viking Masek Automatic Pouch Machines

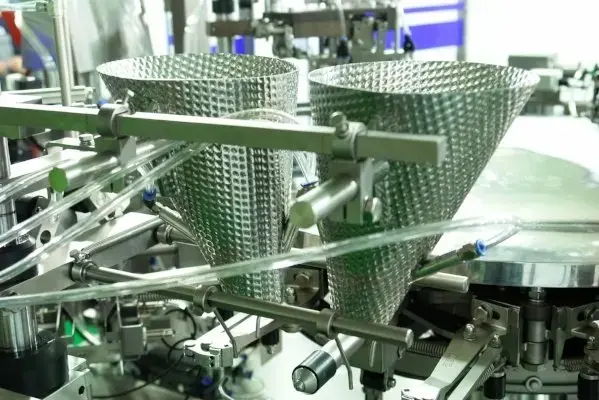

The Viking 8SQ-135 is a 4-lane, dual-rotary automatic pouch machine engineered to deliver the highest throughput in Viking Masek’s lineup — packing up to 200 bags per minute in a compact footprint. By combining 2 double-lane machines on a single platform, it's ideal for maximizing speed without expanding floor space.

Key Features

- Four-lane fill and seal system for ultra-high output

- Ideal for operations with limited space and high-volume needs

- Designed for pouch consistency, seal quality, and efficiency

- Optimized for packaging a variety of food, powder, or dry goods

Specifications

| Number of Stations | 8 |

|---|---|

| Number of Lanes | 4 (2 simplex rotary units) |

| Maximum Speed Per Minute (dry cycle) | 200 |

| Bag Gripping Range | 90-235mm |

| Maximum Bag Length | 350mm |

| Electrical Requirements | 3-Phase, 480V, Approx. 10Kw, 60/50Hz |

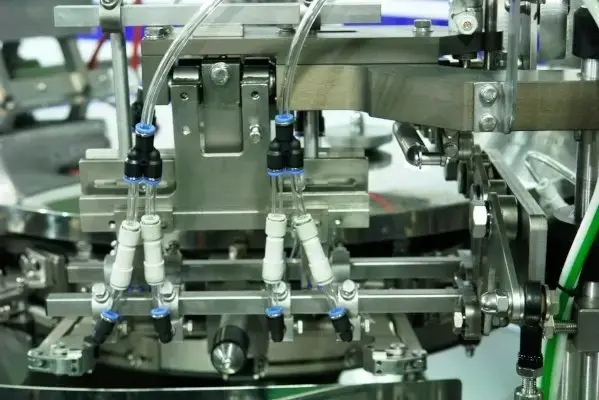

| Compressed Air | Approx. 900 NL/min, 5~6 kgf/cm2 |

Features

- Dual rotary units with 8 stations each, two bags per unit

- Fill and seal 4 bags at once

- Can accommodate 2 different products at once

- PLC control with touch screen operation

- Servo-driven Allen Bradley control platform

- Highly durable welded steel frame

- Production parameter memory including gripper size, machine speed, sealing temperature, and filling volume

- Pouch presence detection – no filling, no sealing

- Bag deflation with wire guide or push bars

- Automatic deoxidizer feeding station

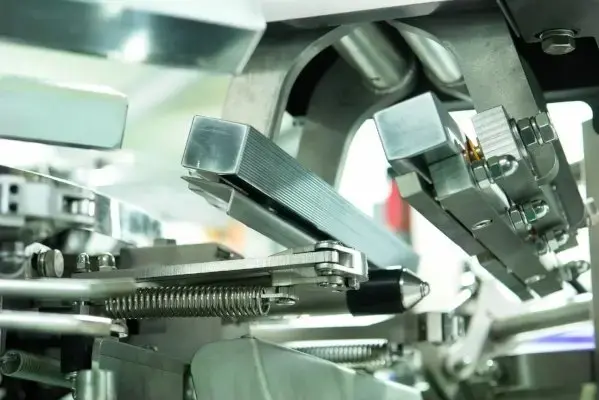

- Two step sealing process guarantees clean sealing

- Cooling station for liquid products

- Intuitive touch screen human interface (HMI)

Max Speed

200 bpm

Bag Size

Min 90 mm W x 120 mm L

Max135 mm W x 350 mm L

Compatible Applications

Food & Beverage

Health & Medical

Options

- Product filling – can be integrated with multi-head scales, volumetric fillers and auger fillers

- Fully interlocked safety guards

- Pre Sealing station for liquid or paste

- Zipper opening device

- Clean-in-place design

- Long raised rotary shaft extender for longer bags

- Extended bag magazine

- Date coding: emboss, hot stamp, inkjet or thermal transfer

- Quality control: checkweigher, metal detector, X-ray inspection

- Dust suction nozzles and dust collector

- Product settler

- Bag supporter for heavy fills

- Ethernet connectivity

- Washdown structure (IP65 or IP66)

- Steam or gas flush

- Rotary running clockwise model

- Bag rejection system

Let’s Talk

Exploring automation for the first time? Looking to simplify or expand a current system? Our team is here to help! No pressure — just a real-world conversation focused on what matters most to your business.