Overview

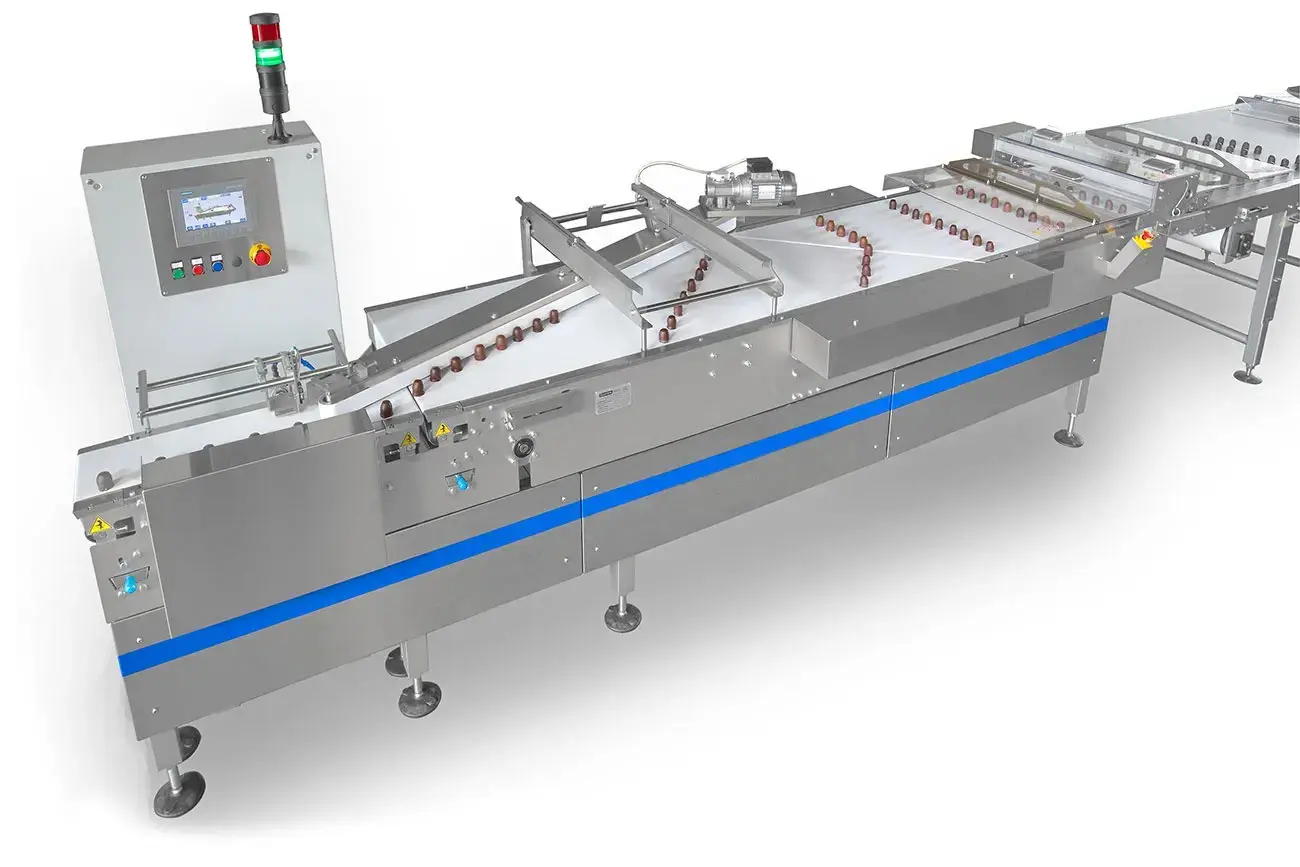

Conveyor Feeding Systems (CFS) Optimize Production

Improve productivity with Conveyor Feeding Systems (CFS) — RDS, POS, and DSS. Expertly designed to seamlessly integrate into your high-volume packaging line, the systems align disordered parts and synchronize speeds for efficient, optimized production.

Features

- Designed for high-volume packaging lines

- Align disordered products and synchronize speeds

- Enhance efficiency and overall productivity

- Support seamless integration into existing lines

- Intuitive touch screen human interface (HMI)

Compatible Applications

Food & Beverage

Health & Medical

Options

RDS (Row Distribution System)

Continuous high-volume production lines demand packaging systems which are able to accept products from the manufacturing process and deliver them to the wrapping machines without manual intervention.

- RDS-DT (Direct Transfer): Rows accelerated directly onto the stationary transverse distribution conveyor

- RDS-IT (Indirect Transfer): Rows accelerated onto a holding station and transferred onto the stationary distribution conveyor when requested by the system

- RDS-ST (Soft Transfer): Rows accelerated onto a holding station and, when requested by the system, transferred onto the stationary transverse distribution conveyor mounted to a trolley that moves laterally, allowing a soft product transfer — ideal for fragile, sticky, or very long products

RAD (Row Alignment Device)

Rows acceptable for automatic distribution are straightened and synchronized by an aligner device, then released to the distribution system.

RDD (Row Discharge Device)

Rows unacceptable for automatic distribution are discharged out of the line onto a transverse auxiliary conveyor via primary feeding conveyor retraction.

RRD (Row Re-feed Device)

Stored rows can be re-fed automatically on the last packaging leg, using one of two RRD versions based on the row rate, product characteristics, and length.

RSD (Row Storage Device)

Untransferred rows can be stored on a conveyor located at the end of the line, after the last transfer station.

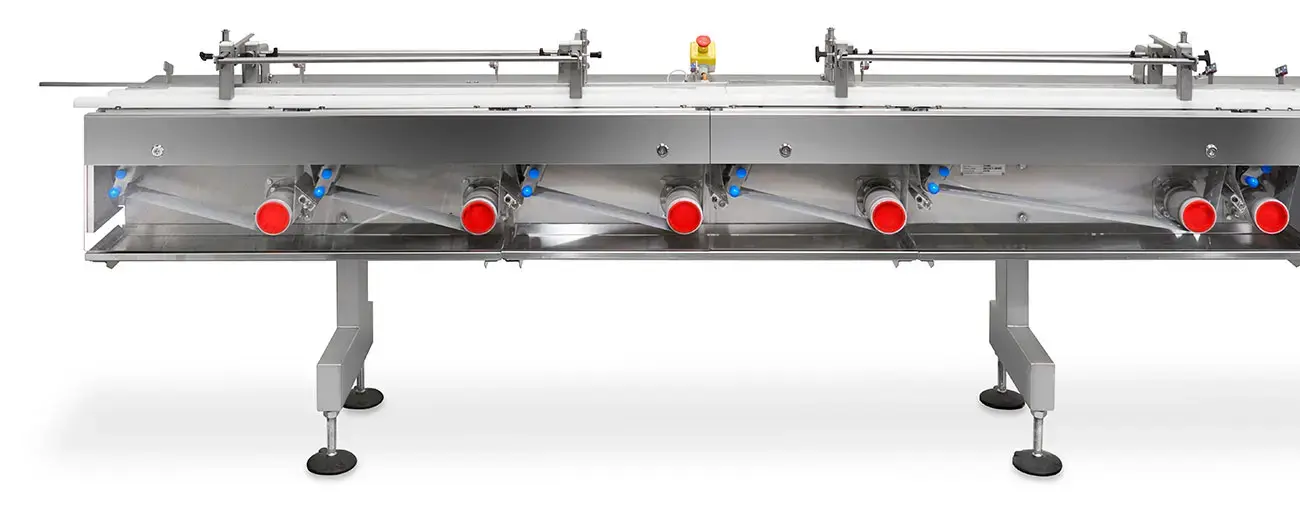

POS (Product Orientation System)

Depending on a product’s characteristics and length, it may arrive in partially oriented rows or in a completely random pattern. Viking Masek offers various product orientation solutions with “stretching” systems that use sequential speed variation, and specially shaped or motorized guides to properly align the products.

DSS (Different Speed Synchronizer)

DSS systems are designed to modulate speeds along the production line and packaging processes to maintain smooth product flow, prevent disruptions, and seamlessly integrate all machines.

Five options are available:

- HSS: High speed synchronizer

- MSS: Medium speed synchronizer

- HPS: High pressure synchronizer

- PLS: Pressure less synchronizer

- LPS: Low pressure synchronizer

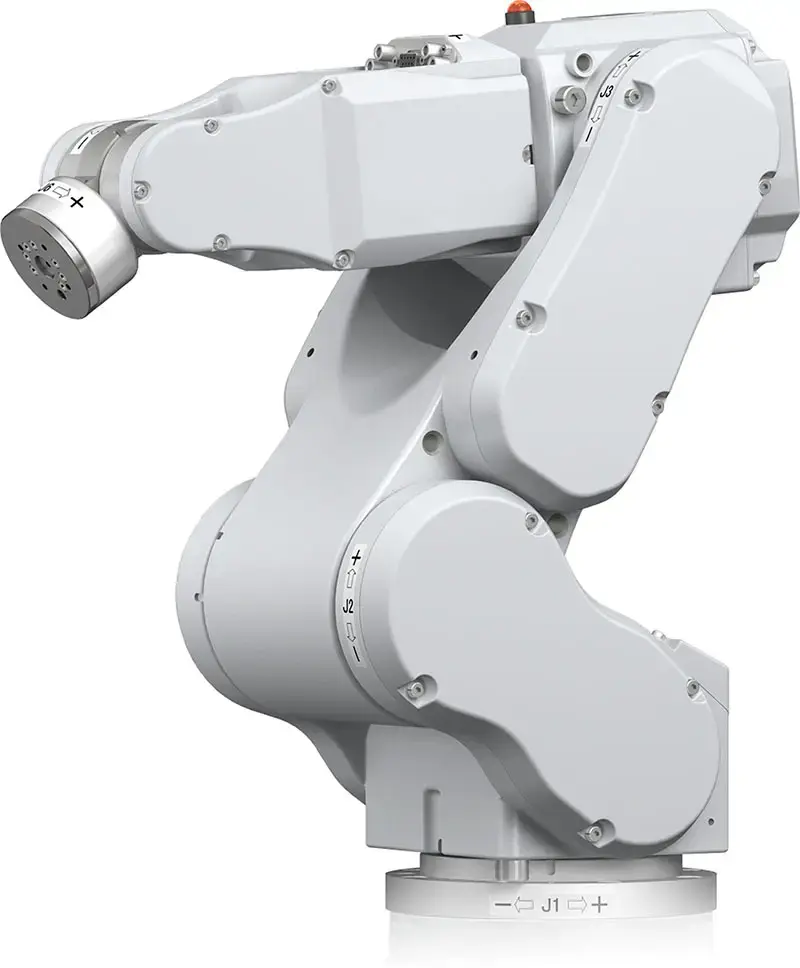

Related Machines

Let’s Talk

Exploring automation for the first time? Looking to simplify or expand a current system? Our team is here to help! No pressure — just a real-world conversation focused on what matters most to your business.