HFS: Handling Feeding Systems

Group, Assemble, and Feed Products for Optimal Flow Wrapping

Overview

Handling Feeding Systems (HFS) Make Packaging Processes Efficient and Fast

Streamline your packaging process with automated handling feeding systems — PAF, SAF, and RAF — engineered to treat products with precision and care during the packaging process. Designed for high flexibility, these systems handle everything from flat-packed to edge-stacked and rolled products across diverse production environments.

Features

- Automates product grouping, assembling, and feeding for flow wrapping

- Efficiently manages flat-packed, edge-stacked, and rolled products

- Ideal for diverse production environments

- Intuitive touch screen human interface (HMI)

Compatible Applications

Food & Beverage

Health & Medical

Options

PAF (Pile Automatic Feeder)

Viking Masek Horizontal Feeding Units are installed at the outfeed end of production lines. They group flat-lying products — biscuits, crackers, sandwich biscuits, toast slices, or cracker breads — into piles and transfer them into the infeed flights of flow-wrapping machines. These modular systems are available in various configurations based on the type of product and the output speed required. Operators can select the desired pile height, from a single layer up to the maximum stable stack, with adjustments made to accommodate product thickness. This height-adjustment feature can be activated without interrupting production, ensuring continuous and efficient operation.

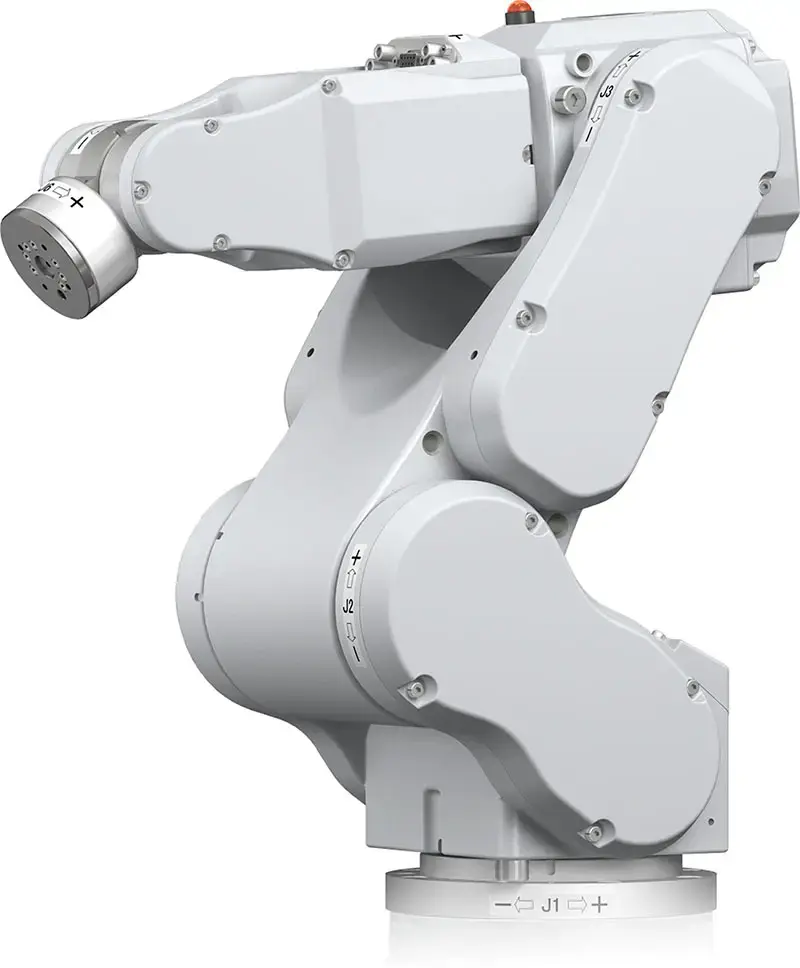

Four-Axis Horizontal Feeding Unit

Powered by four servomotors, the Four-Axis Horizontal Feeding Unit is the top-of-the-line model in its category. It offers maximum flexibility in configuring product piles and allows for pile height adjustments during operation. The machine operates in two main stages: first, product groups are assembled in an intermediate station; then, they are transferred into the in-feed of the flow-wrapping machine. This two-stage process ensures gentle handling and minimizes the risk of product damage.

Two-Axis Horizontal Feeding Unit

The Two-Axis Horizontal Feeding Unit is powered by two servomotors and allows for on-the-fly adjustment of product pile height during operation. The loading and feeding process is performed in a single movement, with piles transferred directly from the incoming lanes into the in-feed of the flow-wrapping machine.

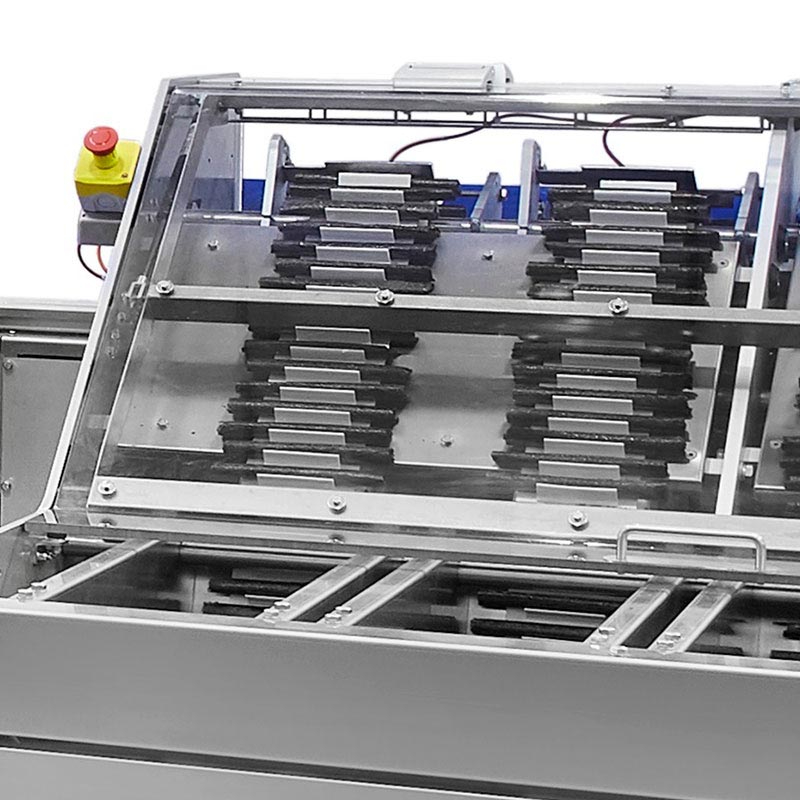

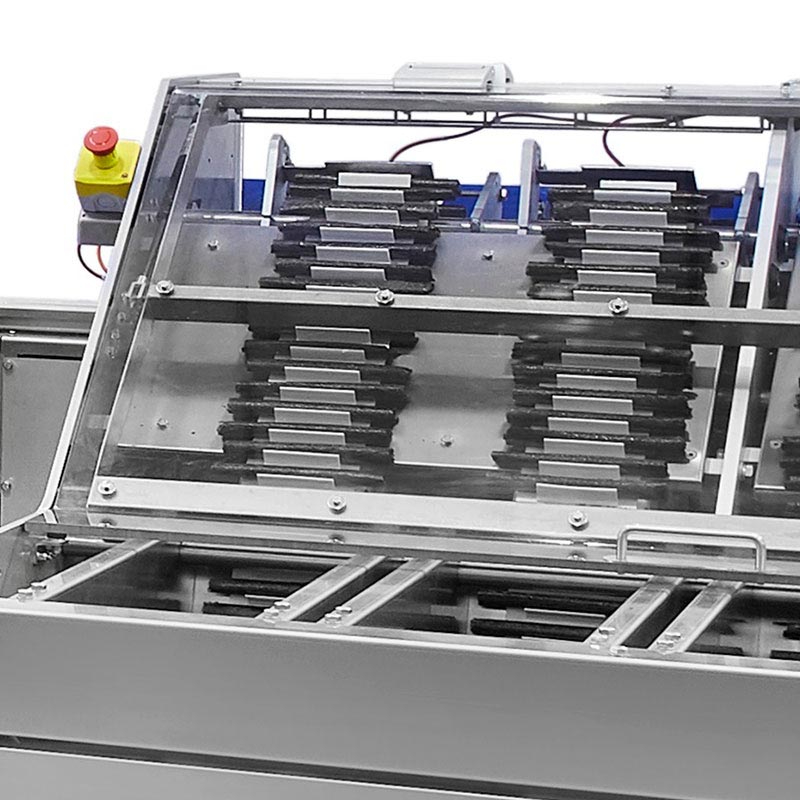

SAF (Slug Automatic Feeder)

The Viking Masek Vertical Loading and Feeding Units are installed at the out-feed end of production lines to assemble products on edge into slugs and transfer them into a flighted conveyor using the Viking Masek 90° Transfer Module. Designed for handling products such as biscuits, crackers, sandwich biscuits, toast slices, and cracker breads, these systems feature a stack length adjustment function that compensates for variations in product thickness and can be activated without stopping production. The modular design is available in various configurations — from as few as 2 or 3 channels up to 16 — depending on the number of incoming lanes and the required output speed. In addition to feeding overwrapping machines via the 90° Transfer Module, the Vertical Feeding Unit can also place products directly into cardboard or plastic trays.

RAF (Roll Automatic Feeder)

The Viking Masek Automatic Feeder for breadsticks receives product directly from the production line and feeds it into the flow-wrapping machine according to the required pack size and breadstick count. The process begins by unloading breadsticks from baking trays and transferring them via a conveyor system to the Feeding Unit. This unit features multiple product hoppers, each designed to match the shape of the breadsticks and the desired output speed. Each hopper is equipped with a release flap, and pack counts are managed using photocells. As stainless steel carrier-equipped conveyors pass in front of the photocells, the correct number of breadsticks is counted and directed into each hopper.

Related Machines

Let’s Talk

Exploring automation for the first time? Looking to simplify or expand a current system? Our team is here to help! No pressure — just a real-world conversation focused on what matters most to your business.