Overview

Liquid Sigma Guarantees Airless Packaging of Liquids

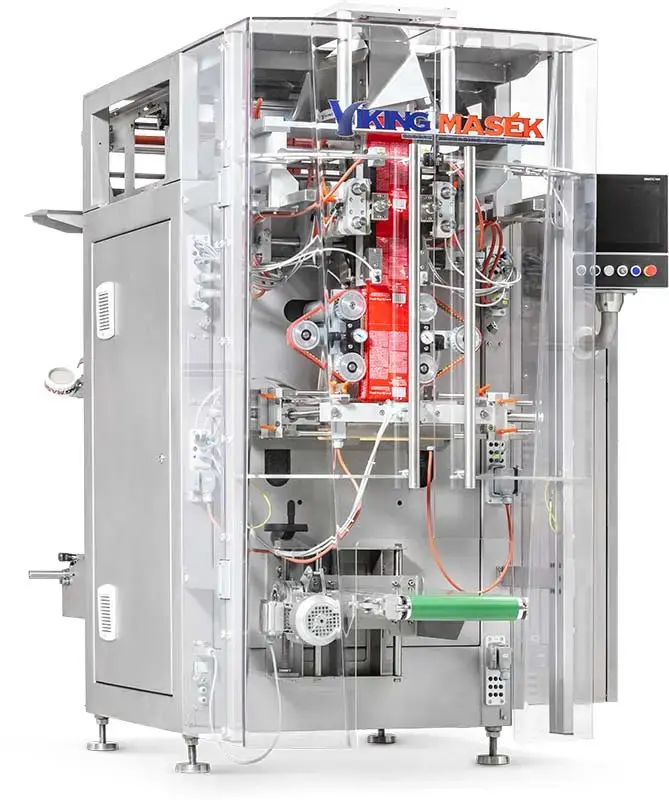

The Viking Masek Liquid Sigma is a continuous motion VFFS machine specifically designed for clean, efficient packaging of liquids such as soups, sauces, and condiments. Its servo-driven, airless squeegee sealing system ensures hygienic seals and smooth operation, even at high speeds. With a center-mounted filling tube, counterbalanced sealing profile, and intuitive controls, the Liquid Sigma delivers unmatched performance and reliability for demanding liquid applications.

Key Features

- Designed specifically for liquid products such as soups, sauces, and condiments

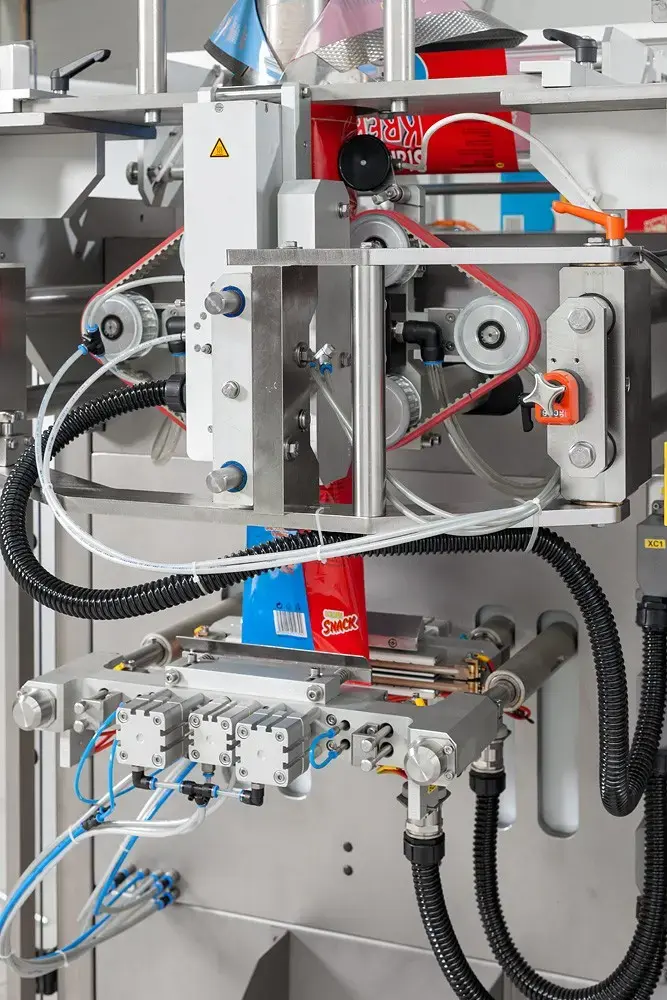

- Servo-driven airless squeegee sealing system for mess-free, hygienic packaging

- Continuous motion operation for smooth, high-speed performance

- Center-mounted filling tube with counterbalanced seal bar for vibration-free runs

- Delivers clean seals and high throughput with industry-leading reliability

Specifications

| Maximum Roll Diameter | 450 mm (17.75") |

|---|---|

| Maximum Roll Width | 645 mm (25.3") |

| Weight | 1,814 kg (4,000 lbs) |

| Air Pressure | 12-18 SCFM at 90 PSI |

| Power Supply | Standard 480V, three phase, 60 Hz. |

Features

- Robust stainless steel frame and parts

- Sanitary design for complete washdown

- Continuous motion

- Enclosed, servo drive jaw actuation

- Servo driven squeegee sealing system for clean, airless liquids packaging

- Open frame design for easy cleaning

- Servo drive for main machine functions

- Vacuum pull belts

- Automatic film tracking

- VFD powered film unwind

- Off-the-shelf components

- Minimal maintenance requirements

- Product stagers

- End-seal cooling air

- Bag deflators

- Photo-eye and encoder

- Film splice table

- Jaw obstruction detection

- Allen Bradley controls

- Storage for 100 product recipes

- Intuitive touch screen human interface (HMI)

Max Speed

60 bpm

Bag Size

Min 60 mm x 120 mm (2.36" x 4.72")

Max300 mm x 1,000 mm (15.75" x 39.37")

Compatible Applications

Options

- Hole punch (Euroslot or Round)

- Tear notch

- Remote diagnostics

- Integration with variety of fillers, printers, metal detectors, label applicators, and checkweighers

Related Machines

Let’s Talk

Exploring automation for the first time? Looking to simplify or expand a current system? Our team is here to help! No pressure — just a real-world conversation focused on what matters most to your business.