Overview

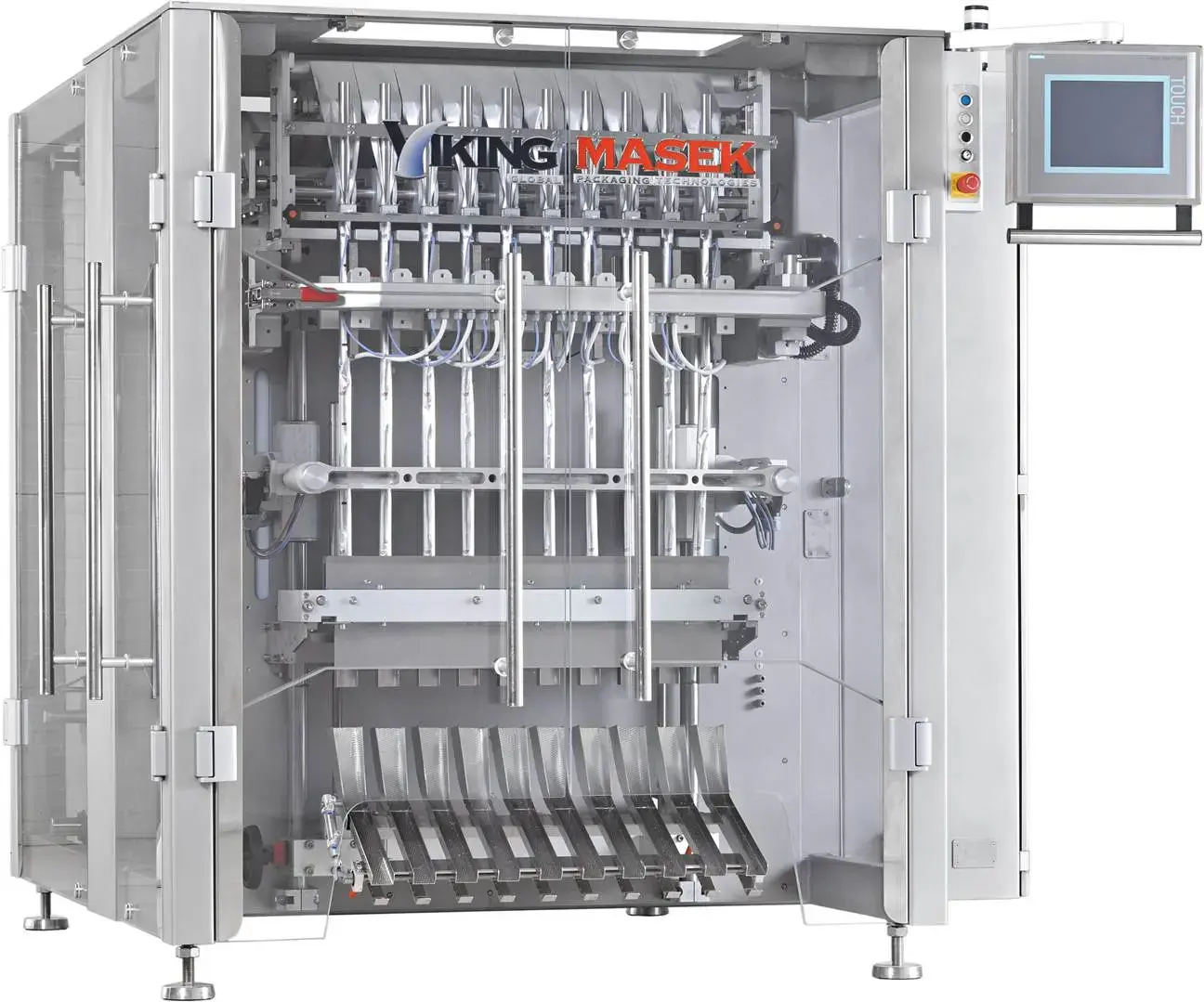

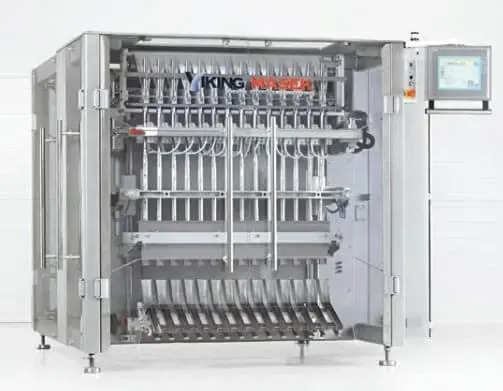

ST1200 Advanced, High-Performance Stick Pack Machine

The state-of-the-art ST1200 stick pack machine represents the pinnacle of packaging technology, capable of operating up to 20 lanes simultaneously for maximum production efficiency. Engineered to handle a diverse range of materials, from dense and fine powders to loose particulates, liquids, and gels, the ST1200 delivers exceptional flexibility and performance for modern production lines requiring high-volume output and versatility.

Key Features

- High-speed output with up to 20 simultaneous lanes

- Processes diverse materials including fine powders, particulates, liquids, and gels

- Customizable pouch formats with pour spouts, tear notches, and easy-open options

- Fully compatible with automated cartoning solutions

- Advanced technology for precision filling and consistent quality

Specifications

| Maximum Roll Diameter | 450 mm (17.75") |

|---|---|

| Maximum Roll Width | 1200 mm (47.24") |

| Weight | 1,600 kg (3,525 lbs) |

| Air Pressure | 6 bar (15 CFM at 90 PSI) |

| Power Supply | 10 kVA (480 V, three phase, 60 Hz., 20 AMPS) |

Features

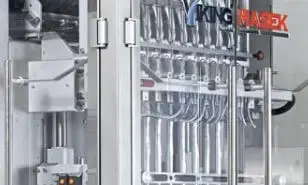

- Powered film unwind

- Film slitters and forming tubes - set per bag size

- Discharge chute

- Siemens or Allen Bradley control system

- Automatic film tracking

- Integrated inner light

- GMP construction

- Intuitive touch screen human interface (HMI)

Max Speed

50 cpm

Bag Size

Min 17 mm x 40 mm (0.67" x 1.57")

Max100 mm x 200 mm (3.94" x 7.88")

Compatible Applications

Health & Medical

Options

- Straight cut

- Zigzag cut

- Round cut

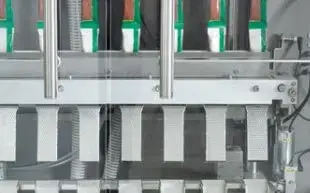

- Multi-lane volumetric filler, servo auger filler or servo liquid fillers

- Easy change-over parts and stainless storage cart

- Easy open features like tear notch or microperforation

- Various seal patterns and shapes

- Offset back seal

- Automatic stick pack length adjustment

- Individual discharge chutes

- Empty stick detection

- Empty stick rejection

- Dust suction nozzles

- Static elimination

- Film edge trimming and suction

- Embossing in the longitudinal seal

- Stainless steel construction

- Pharma construction (IQ/OQ)

- Robotic pick-and-place unit and automatic cartoning solutions

- Hot stamp, inkjet, or thermal transfer printer

- Infeed and outfeed conveyors

Let’s Talk

Exploring automation for the first time? Looking to simplify or expand a current system? Our team is here to help! No pressure — just a real-world conversation focused on what matters most to your business.