Overview

Stick Packs Fit a Wide Variety of Industry Needs

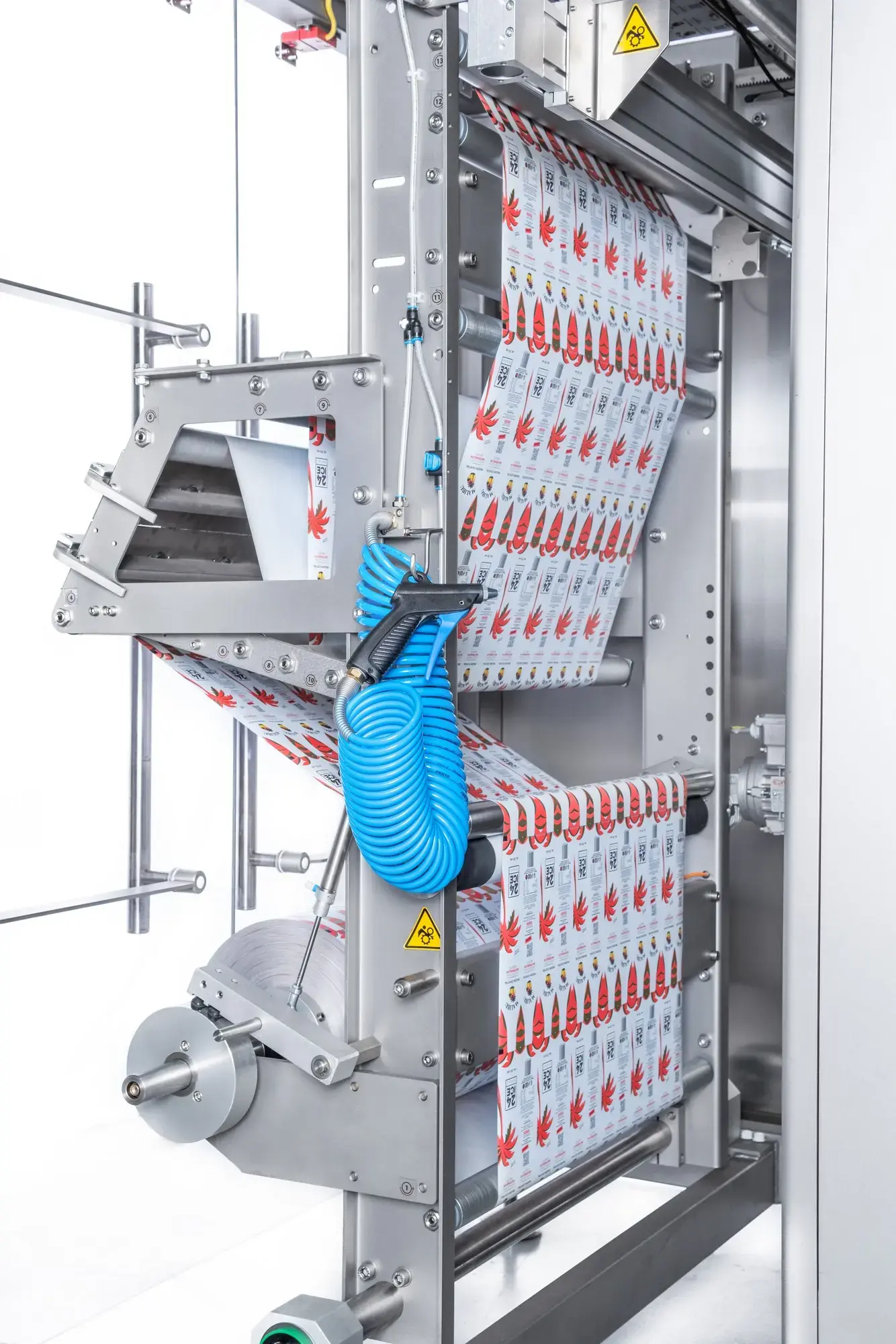

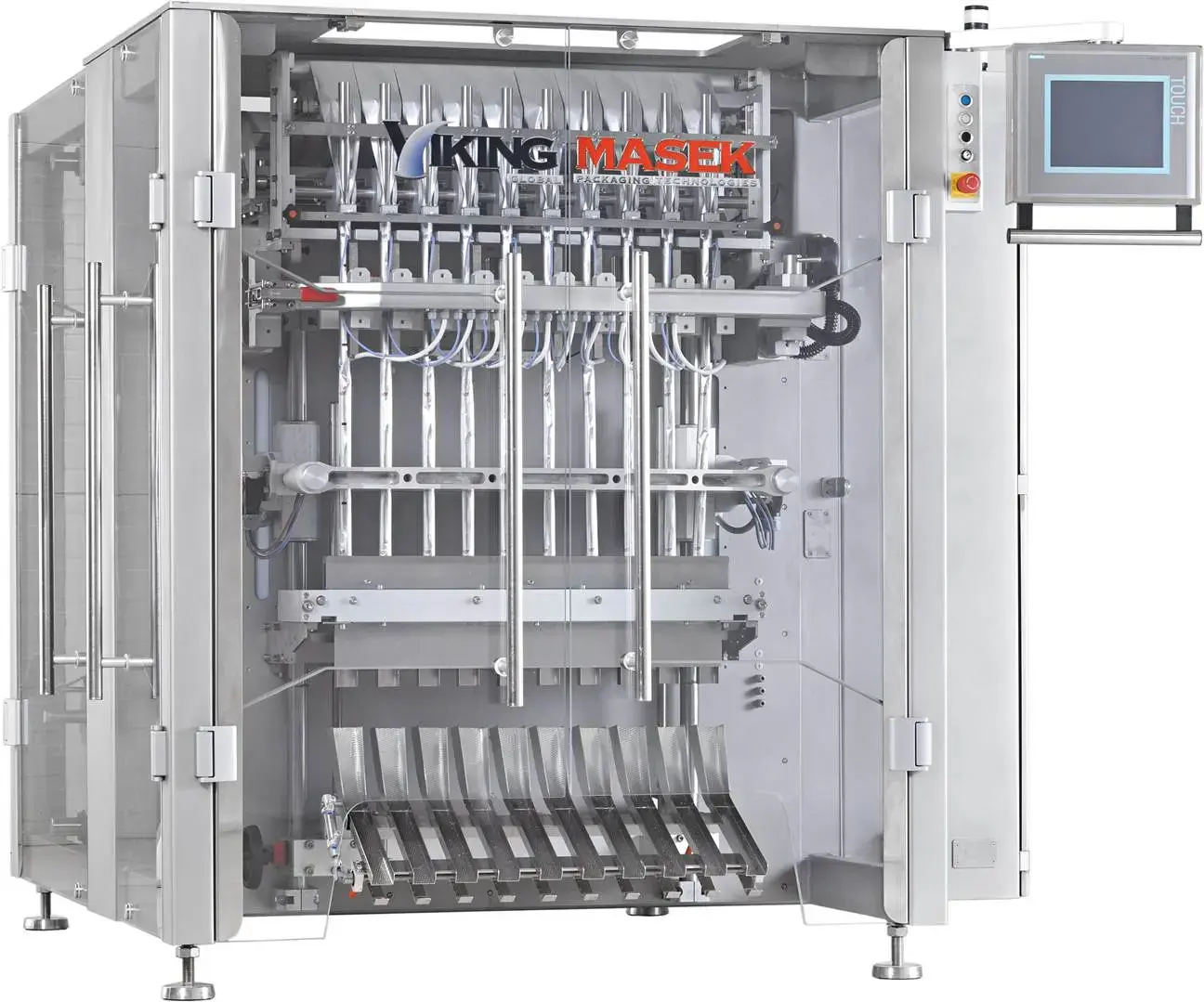

Looking for maximum flexibility in stick pack packaging? The servo-driven ST600 stick pack machine handles 2 to 14 lanes and supports both powder and liquid fillers, producing high-quality stick packs up to 60 mm wide and 200 mm long with ease. Designed for packaging coffee, drink mixes, cannabis, and more, the ST600 offers exceptional versatility and presentation.

Key Features

- Supports 2–14 lanes for multi-lane production

- Compatible with both powder and liquid fillers

- Produces stick packs up to 60 mm wide x 200 mm long

- Custom pouch options: pour spouts, tear notches, easy-open features

- Fully automated cartoning solutions available

- Engineered for efficiency, flexibility, and premium presentation

Specifications

| Maximum Roll Diameter | 450 mm (17.75") |

|---|---|

| Maximum Roll Width | 600 mm (23.62") |

| Weight | 800 kg (1,765 lbs) |

| Air Pressure | 6 bar (30 CFM at 90 PSI) |

| Power Supply | 6.5 kVA (480 V, three phase, 60 Hz., 20 AMPS) |

Features

- Powered film unwind with film tension control

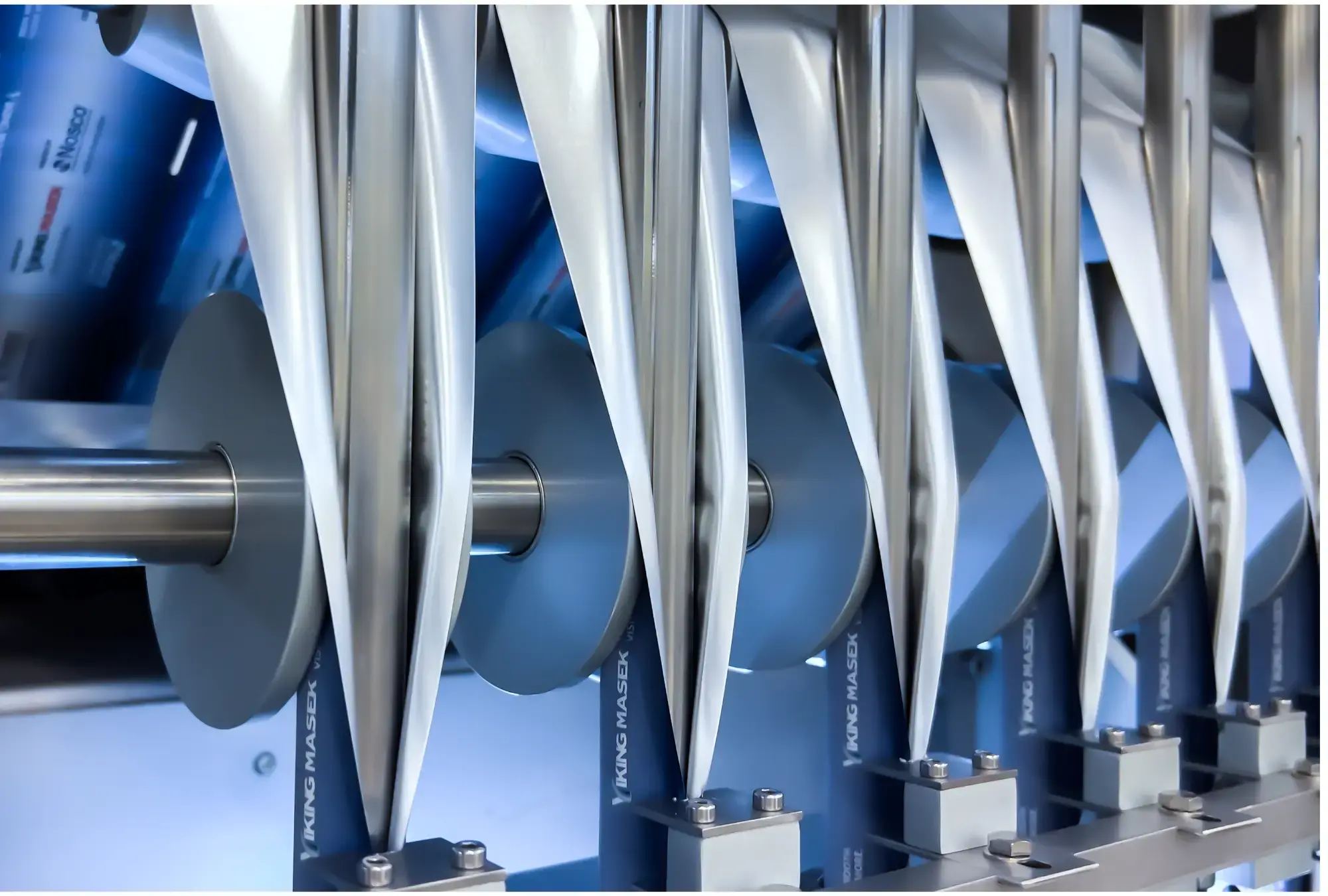

- Film slitters and forming tubes - set per bag size

- Discharge chute

- Siemens or Allen Bradley control system

- Automatic film tracking

- Integrated inner light

- GMP construction

- Easy change-over

- Intuitive touch screen human interface (HMI)

Max Speed

80 cpm

Bag Size

Min 17 mm x 40 mm (0.67" x 1.57")

Max60 mm x 200 mm (2.38" x 7.88")

Compatible Applications

Health & Medical

Options

- Straight cut

- Zigzag cut

- Round cut

- Multi-lane volumetric filler, servo auger filler, piston liquid filler, or servo liquid fillers

- Easy change-over parts and stainless storage cart

- Easy open features like tear notch or microperforation

- Various seal patterns and shapes

- Offset back seal

- Automatic stick pack length adjustment

- Individual discharge chutes

- Empty stick detection

- Empty stick rejection

- Dust suction nozzles

- Static elimination

- Film edge trimming and suction

- Embossing in the longitudinal seal

- Stainless steel construction

- Pharma construction (IQ/OQ)

- Robotic pick-and-place unit and automatic cartoning solutions

- Hot stamp, inkjet, or thermal transfer printer

- Infeed and outfeed conveyors

Let’s Talk

Exploring automation for the first time? Looking to simplify or expand a current system? Our team is here to help! No pressure — just a real-world conversation focused on what matters most to your business.