Overview

Flow Wrappers for Irregular, Fragile, Sticky, and Hard-to-Handle Products

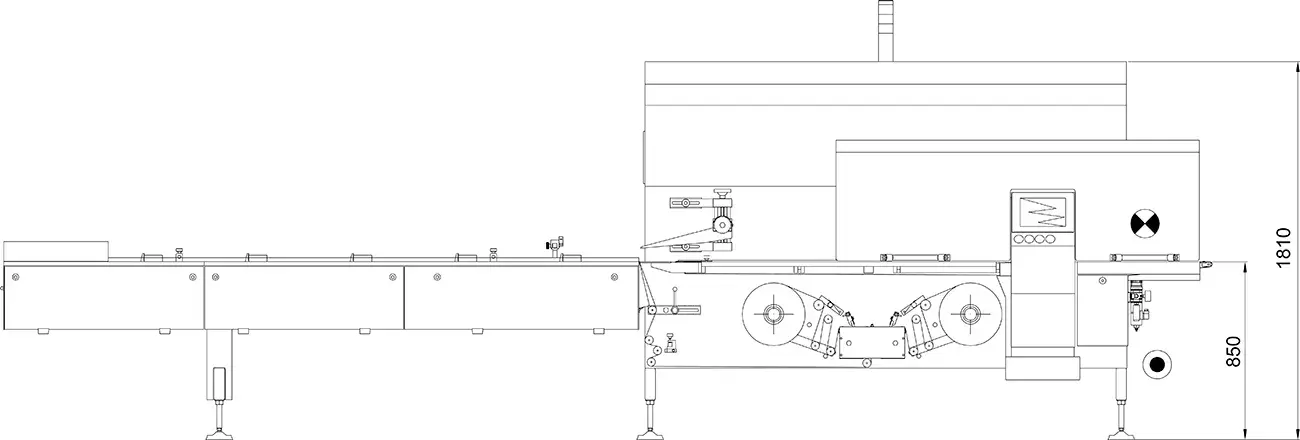

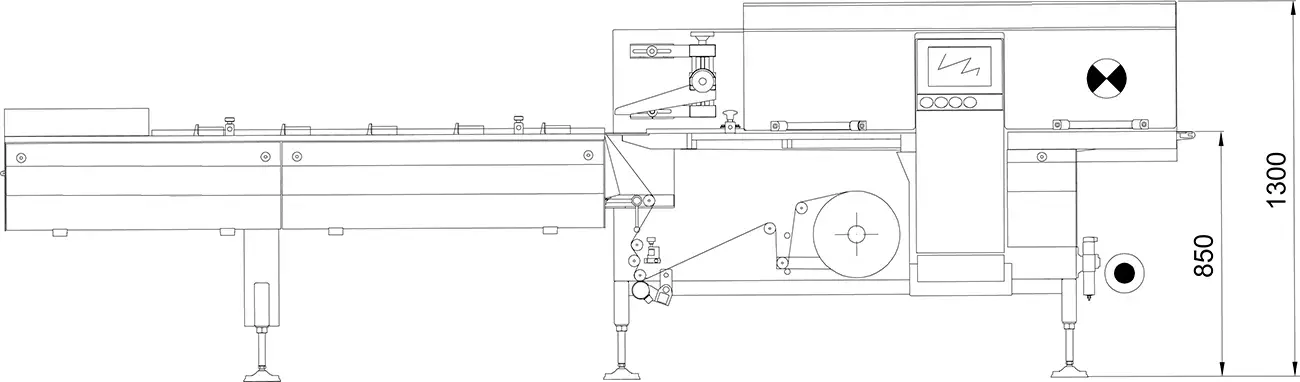

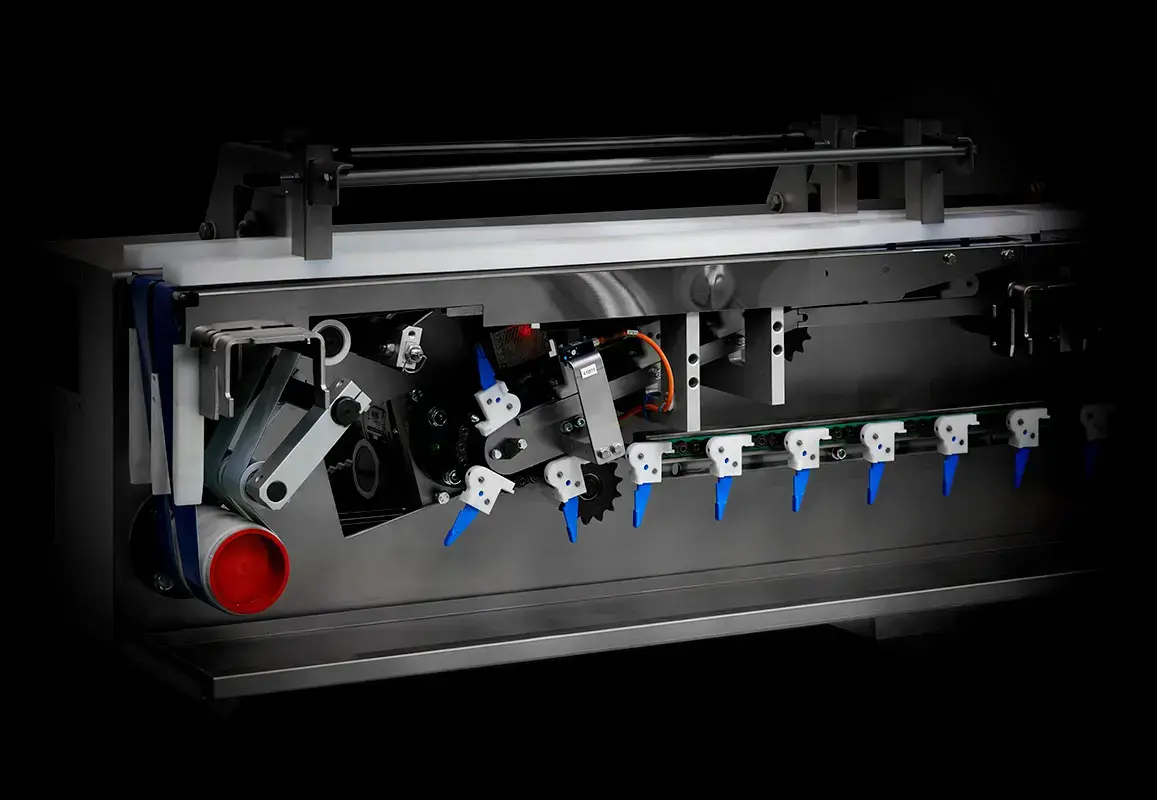

Built to handle even the most delicate and challenging products, the FW-60 and FW-600 Flow Wrappers (with bottom film reel holders) offer servo-driven performance and a shared modular platform for high flexibility, ease of use, and low maintenance across diverse production environments.

Key Features

- Optimized for delicate and challenging products

- Servo-driven technology for precision and adaptability

- Robust, cantilevered construction for hygiene and maintenance access

- Modular platform supports multiple configurations and accessories

- Compatible with a wide range of feeding systems and add-ons

- Designed for high performance and fast changeovers in demanding environments

Specs PDFs

Specifications

| Safety Compliance | CE Directive 98/37/CE CE Directive 89/336 CEE - 93/68/CEE CE Directive 72/23 CEE - 93/68/CEE EN 415-3 / EN 60204-1 / EN ISO 12100-1 / EN ISO 12100-2 / EN 294 / EN 418 |

|---|---|

| Power Supply | 480V 3ph |

| Electrical Consumption | 12 - 32 amps |

| Air Consumption | 2 cfm @ 90 psi |

| Noise Level | Less than 80 db |

| Weight | Between 2,200 - 3,300 lbs |

Features

- Pusher conveyor

- Bottom reel holder

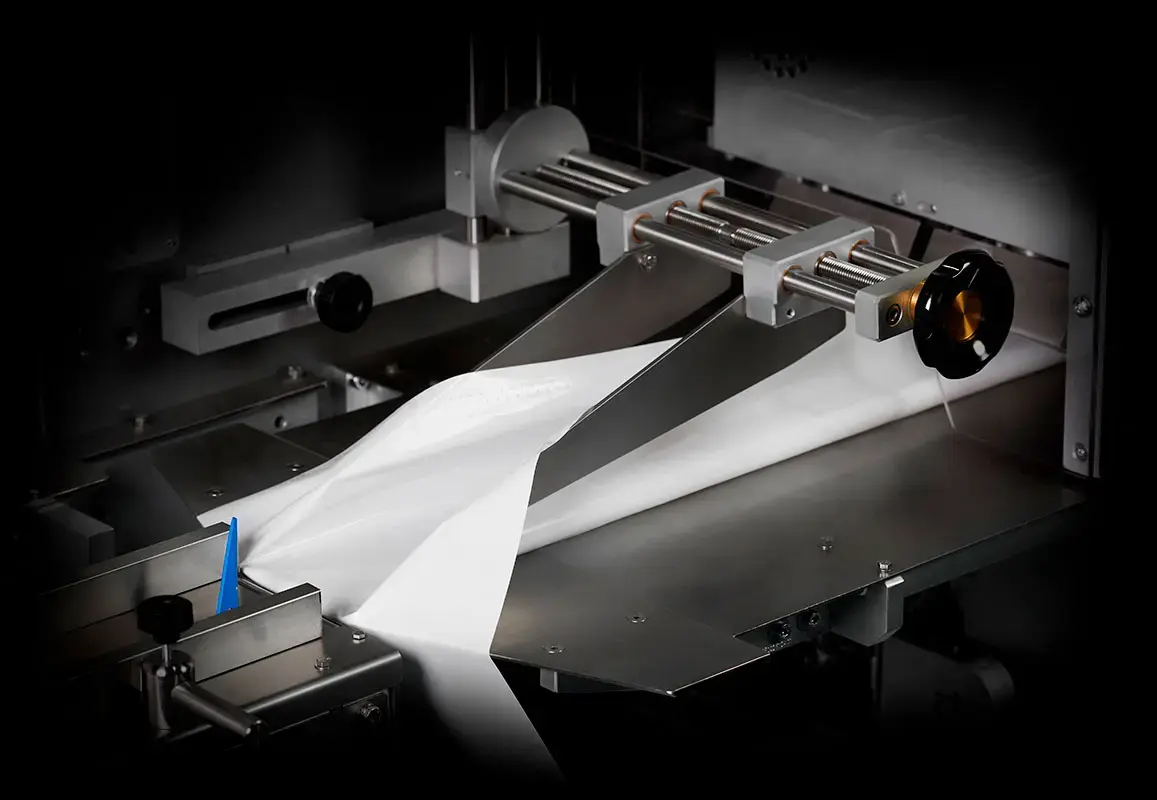

- Reel holder with reel edge alignment device

- Universal forming box

- Fin longitudinal sealing unit

- Longitudinal sealing unit

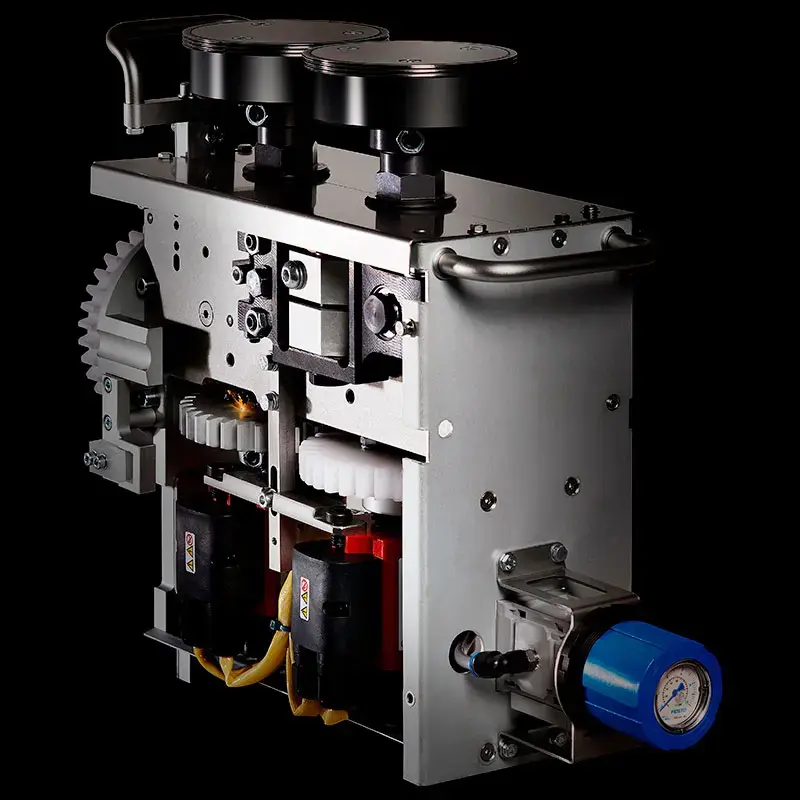

- Longitudinal welding module

- Outfeed conveyor with ejection

- Transmission cabinet

- Allen Bradley Controls

- Intuitive touch screen human interface (HMI)

- Outfeed conveyor

- End cutting and welding unit

- Easy changeover

- Modular construction

- Minimal maintenance requirements

- Poly configuration for polyethylene films

- Cold configuration for cold sealing films

- Box Motion configuration for hermetic sealing

- Robust stainless steel build

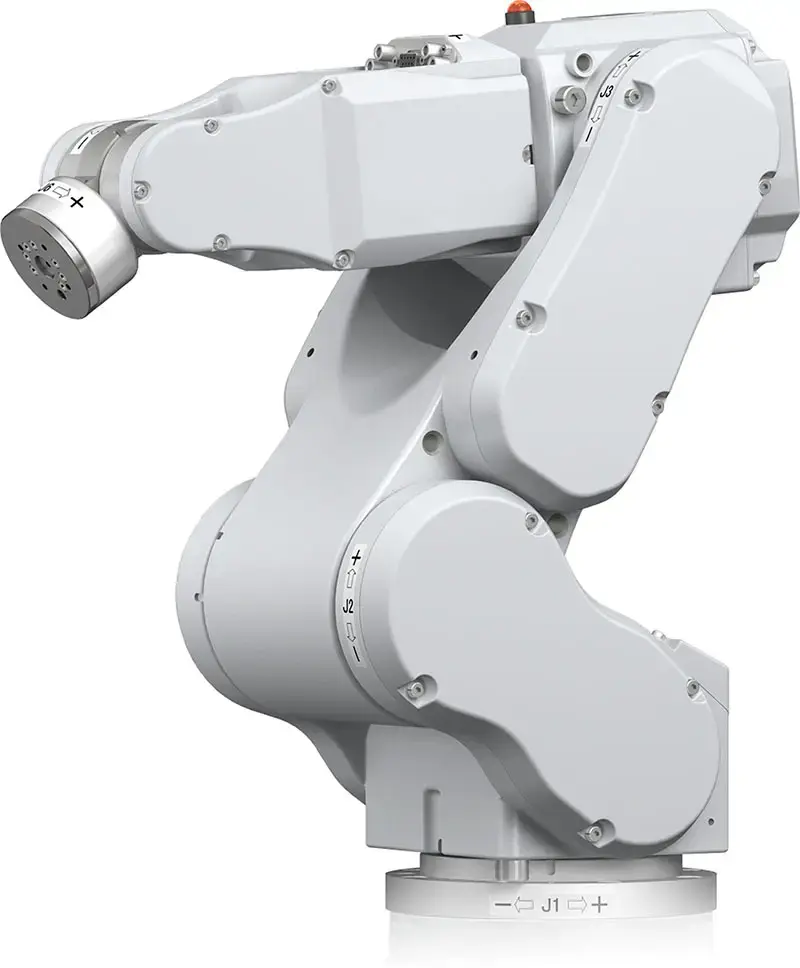

- Robotic handling configuration for right hand execution

- Integration with feeders

- Integration with ancillary equipment

- Automatic film splice

Compatible Applications

Food & Beverage

Health & Medical

Options

- Poly configuration for polyethylene films

- Cold configuration for cold sealing films

- Box Motion configuration for hermetic sealing

- Robotic handling for right hand execution

- Integration with feeders

- Integration with ancillary equipment

Related Machines

Let’s Talk

Exploring automation for the first time? Looking to simplify or expand a current system? Our team is here to help! No pressure — just a real-world conversation focused on what matters most to your business.