7SU-240

Versatile, Two-Lane rotary Machine Fills and Seals Premade Pouches For a Variety of Applications

Overview

Increase Your Throughput, Quality, and Bottom Line

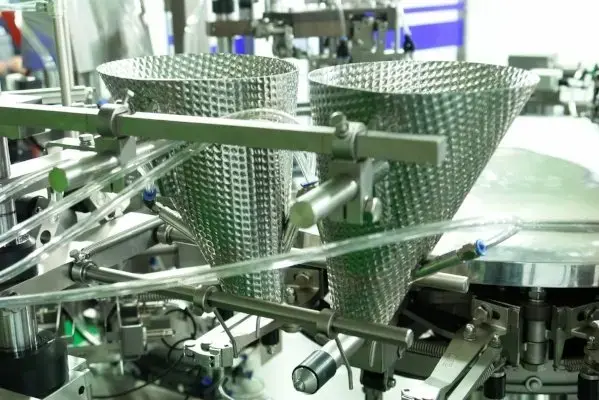

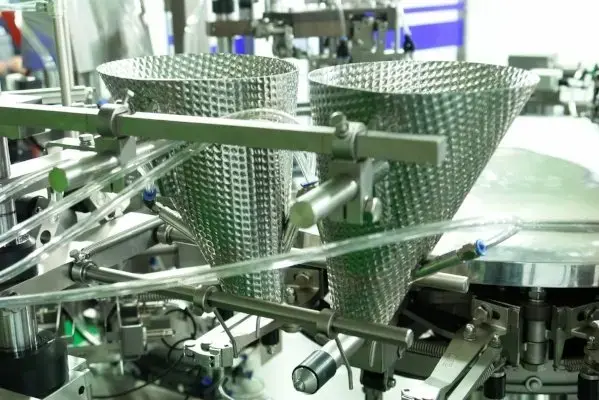

The Viking 7SU-240 is a two-lane rotary premade pouch machine designed for high-speed, efficient filling and sealing of preformed pouches up to 165 mm wide. With duplex output and speeds reaching 100 cycles per minute, it's an ideal solution for industries requiring both precision and performance in medium-format pouch applications.

Key Features

- Two-lane rotary system for dual pouch output

- Speeds up to 100 CPM for rapid production

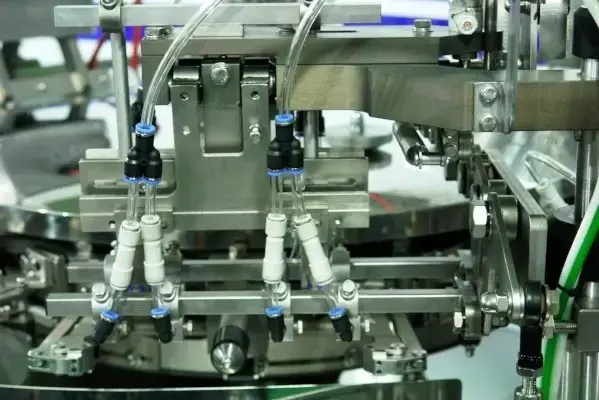

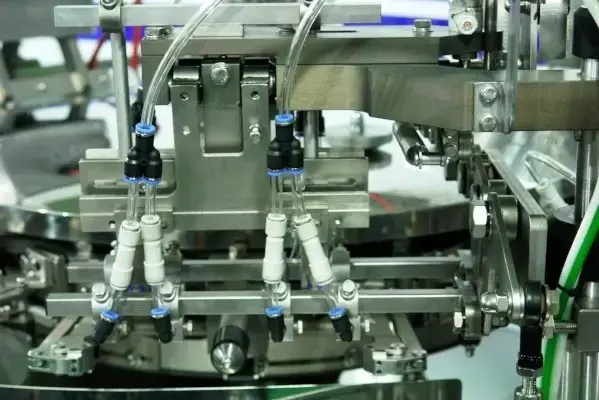

- Compatible with multi-head scales, augers, and volumetric fillers

- Optional cooling station available for liquid product compatibility

Specifications

| Number of Stations | 7 |

|---|---|

| Number of Lanes | 2 |

| Maximum Speed Per Minute (dry cycle) | 80 |

| Bag Gripping Range (mm) | 100-240mm |

| Maximum Bag Length (mm) | 350mm |

| Electrical Requirements | 3-Phase, 480V, Approx. 10 Kw, 60Hz |

| Compressed Air | Approx. 1,00NL/min, 8kgf/cm2 |

Features

- 7 stations, dual bags

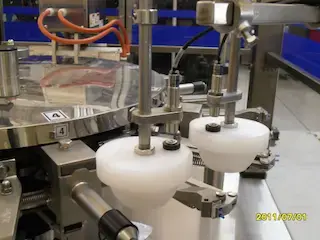

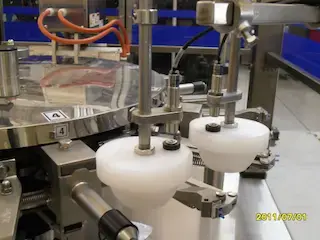

- Dual grippers (no center gripper)

- PLC control with touch screen operation

- Servo-driven Allen Bradley control platform

- Highly durable welded steel frame

- Production parameter memory including gripper size, machine speed, sealing temperature, and filling volume

- Pouch presence detection – no filling, no sealing

- Bag deflation with wire guide or push bars

- Automatic deoxidizer feeding station

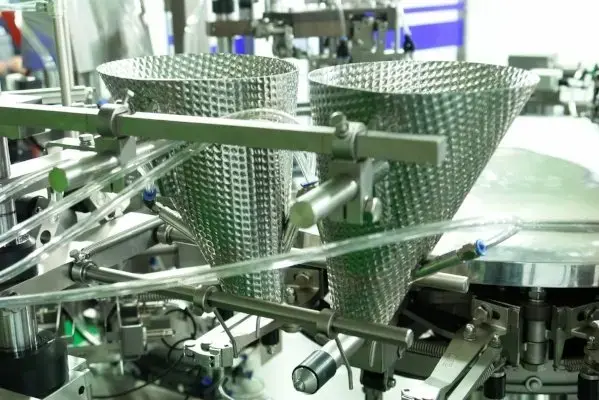

- Two step sealing process guarantees clean sealing

- Cooling station for liquid products

- Intuitive touch screen human interface (HMI)

Max Speed

80 bpm

Bag Size

Min 100 mm W x 120 mm L

Max240 mm W x 350 mm L

Compatible Applications

Food & Beverage

Health & Medical

Options

- Proprietary Viking robotic pick & place bag infeed system

- Product filling – can be integrated with multi-head scales, volumetric fillers and auger fillers

- Fully interlocked safety guards

- Pre Sealing station for liquid or paste

- Zipper opening device

- Clean-in-place design

- Long raised rotary shaft extender for longer bags

- Extended bag magazine

- Date coding: emboss, hot stamp, inkjet or thermal transfer

- Quality control: checkweigher, metal detector, X-ray inspection

- Dust suction nozzles and dust collector

- Product settler

- Bag supporter for heavy fills

- Ethernet connectivity

- Washdown structure (IP65 or IP66)

- Steam or gas flush

- Rotary running clockwise model

- Bag rejection system

- Collating discharge conveyor

Let’s Talk

Exploring automation for the first time? Looking to simplify or expand a current system? Our team is here to help! No pressure — just a real-world conversation focused on what matters most to your business.