Overview

The High-Speed Duplex Premade Pouch Filler and Sealer for rapid Mid-Capacity Production

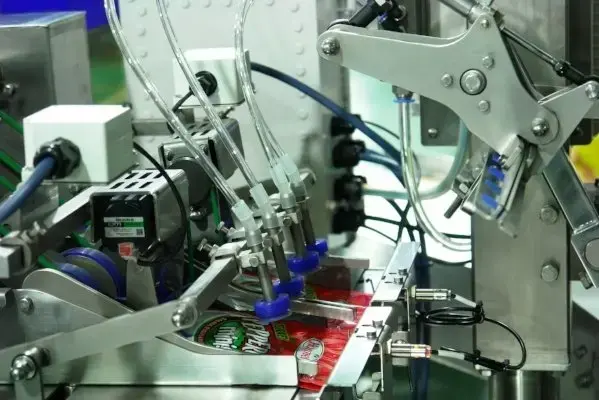

The Viking 8SD-135 is a high-speed, 8-station duplex rotary premade pouch machine engineered for rapid, dual-bag filling and sealing. Customized to meet specific production needs, this system delivers speeds of up to 100 cycles per minute, making it an excellent choice for mid-capacity production environments.

Key Features

- Speeds up to 100 CPM, ideal for mid-capacity production environments

- Saves settings: gripper size, sealing temp, speed, and fill volume

- Pouch presence detection ensures waste-free operation

- Bag deflation system via wire guide or push bars

Specifications

| Number of Stations | 8 |

|---|---|

| Number of Lanes | 2 |

| Maximum Speed Per Minute (dry cycle) | 100 |

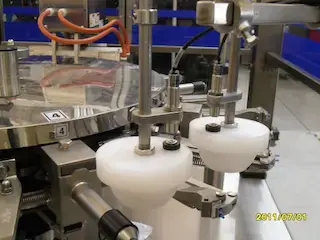

| Bag Gripping Range (mm) | 90-135mm |

| Maximum Bag Length (mm) | 350mm |

| Electrical Requirements | 3-Phase, 480V, Approx. 8.5 Kw, 60Hz |

| Compressed Air | Approx. 900 NL/min, 5~6 kgf/cm2 |

Features

- 8 stations, dual bags

- PLC control with touch screen operation

- Servo-driven Allen Bradley control platform

- Highly durable welded steel frame

- Production parameter memory including gripper size, machine speed, sealing temperature, and filling volume

- Pouch presence detection – no filling, no sealing

- Bag deflation with wire guide or push bars

- Automatic deoxidizer feeding station

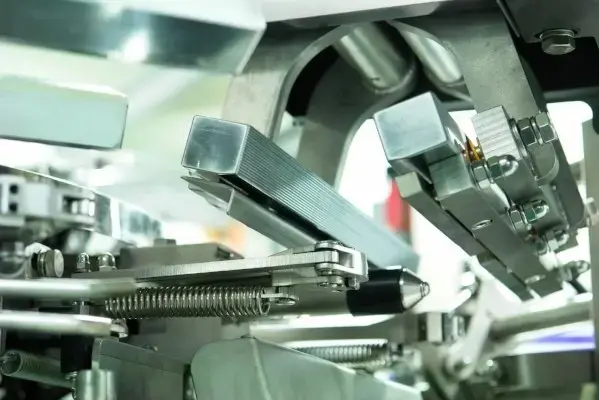

- Two step sealing process guarantees clean sealing

- Cooling station for liquid products

- Intuitive touch screen human interface (HMI)

Max Speed

100 bpm

Bag Size

Min 90 mm W x 120 mm L

Max135 mm W x 350 mm L

Compatible Applications

Food & Beverage

Health & Medical

Options

- Proprietary Viking robotic pick & place bag infeed system

- Product filling – can be integrated with multi-head scales, volumetric fillers and auger fillers

- Fully interlocked safety guards

- Pre Sealing station for liquid or paste

- Zipper opening device

- Clean-in-place design

- Long raised rotary shaft extender for longer bags

- Extended bag magazine

- Date coding: emboss, hot stamp, inkjet or thermal transfer

- Quality control: checkweigher, metal detector, X-ray inspection

- Dust suction nozzles and dust collector

- Product settler

- Bag supporter for heavy fills

- Ethernet connectivity

- Washdown structure (IP65 or IP66)

- Steam or gas flush

- Rotary running clockwise model

- Bag rejection system

- Collating discharge conveyor

Let’s Talk

Exploring automation for the first time? Looking to simplify or expand a current system? Our team is here to help! No pressure — just a real-world conversation focused on what matters most to your business.