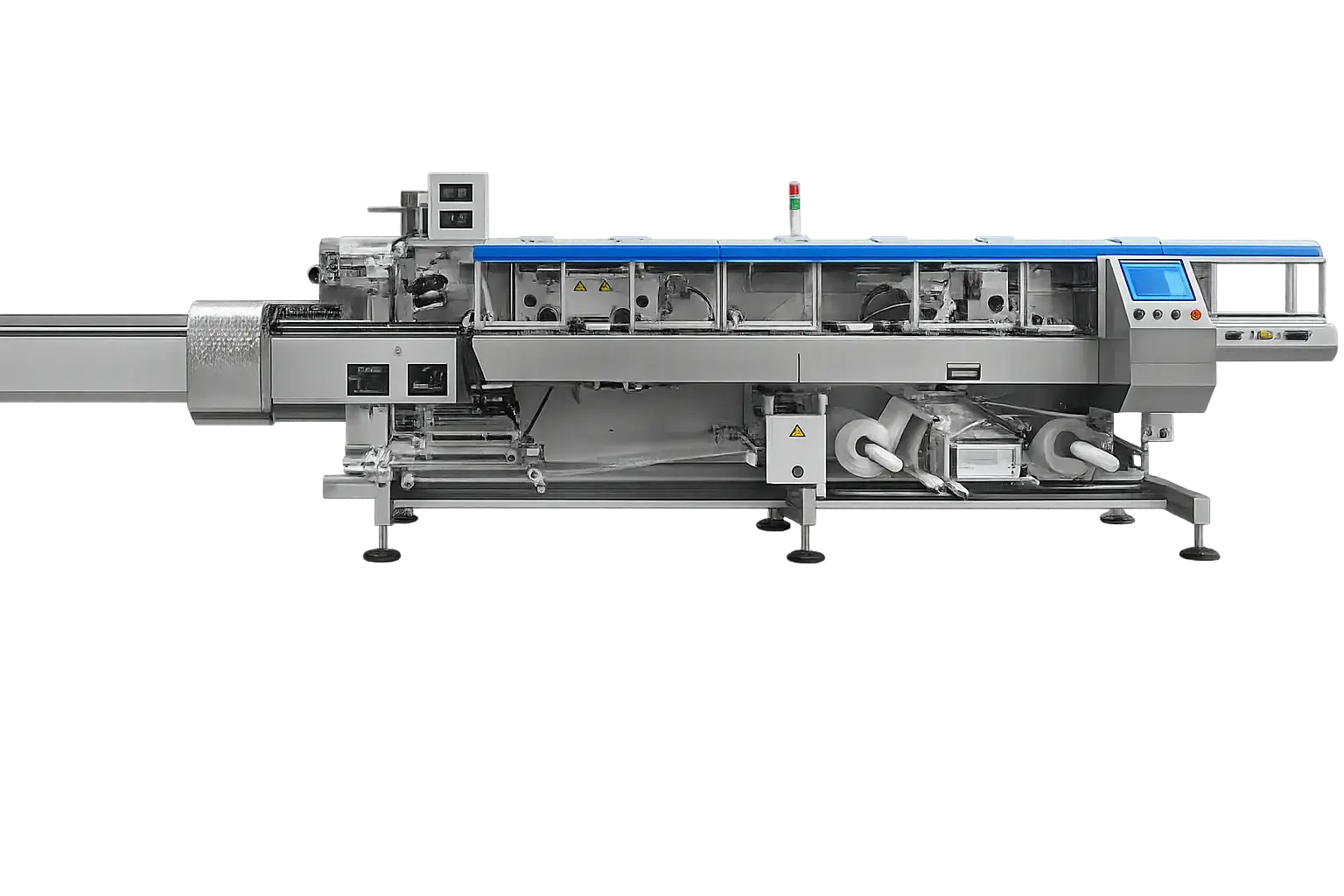

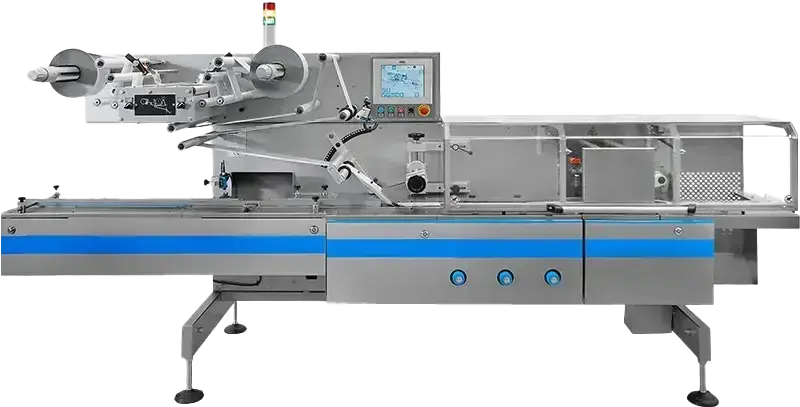

FW-600

High-Speed Horizontal Flow Wrapper for Irregular, Sticky, and Delicate Products

Overview

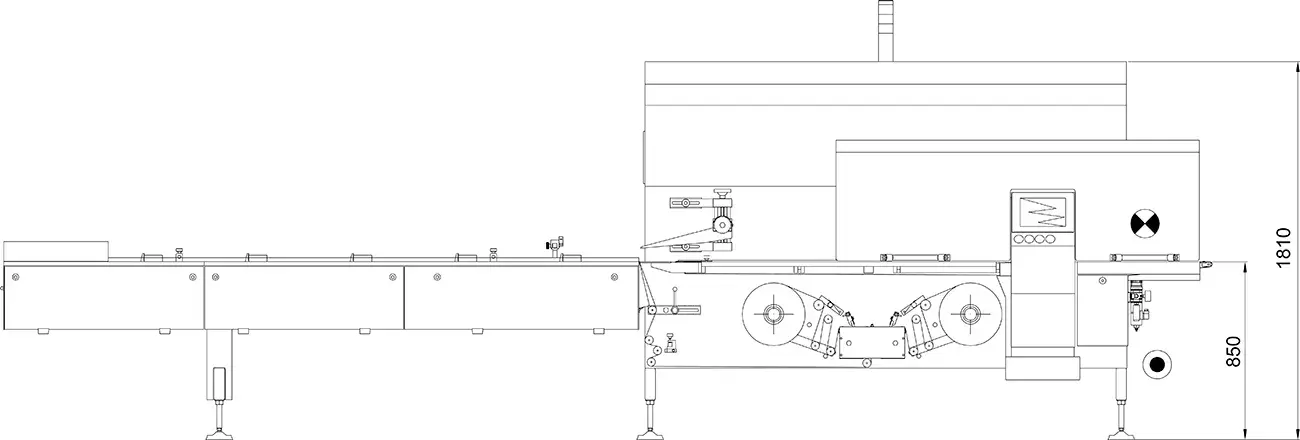

The FW-600 is built to package irregular, sticky, and delicate products with speed and precision. A bottom film reel holder and servo-driven controls ensure smooth operation, and the stainless steel frame, modular layout, and easy changeovers make it ideal for high-speed production environments. With output up to 500 bpm, the FW 600 offers flexibility, performance, and reliability for demanding packaging lines.

Key Features

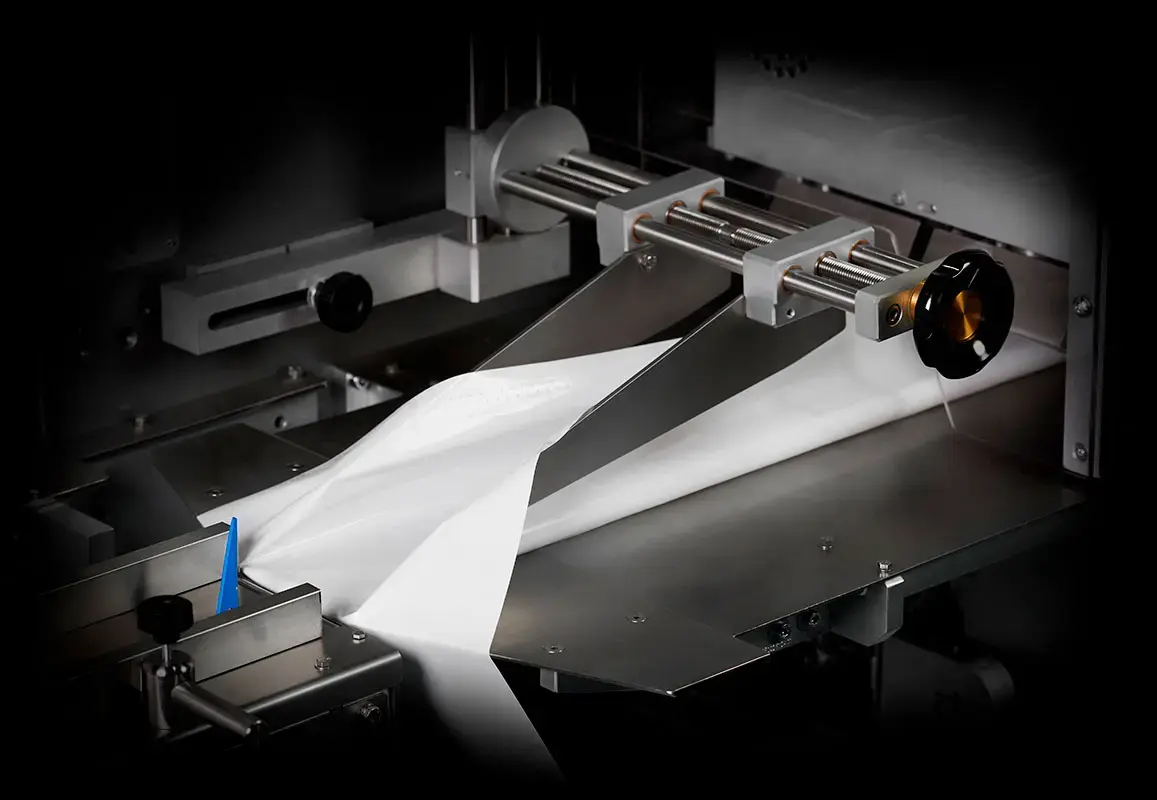

- Bottom film reel holder for smooth product handling

- Servo-driven controls with speeds up to 500 bpm

- Handles sticky, delicate, or irregular products

- Modular stainless steel construction

- Tool-free changeovers with 10.4” touchscreen HMI

- Low maintenance with robust, hygienic design

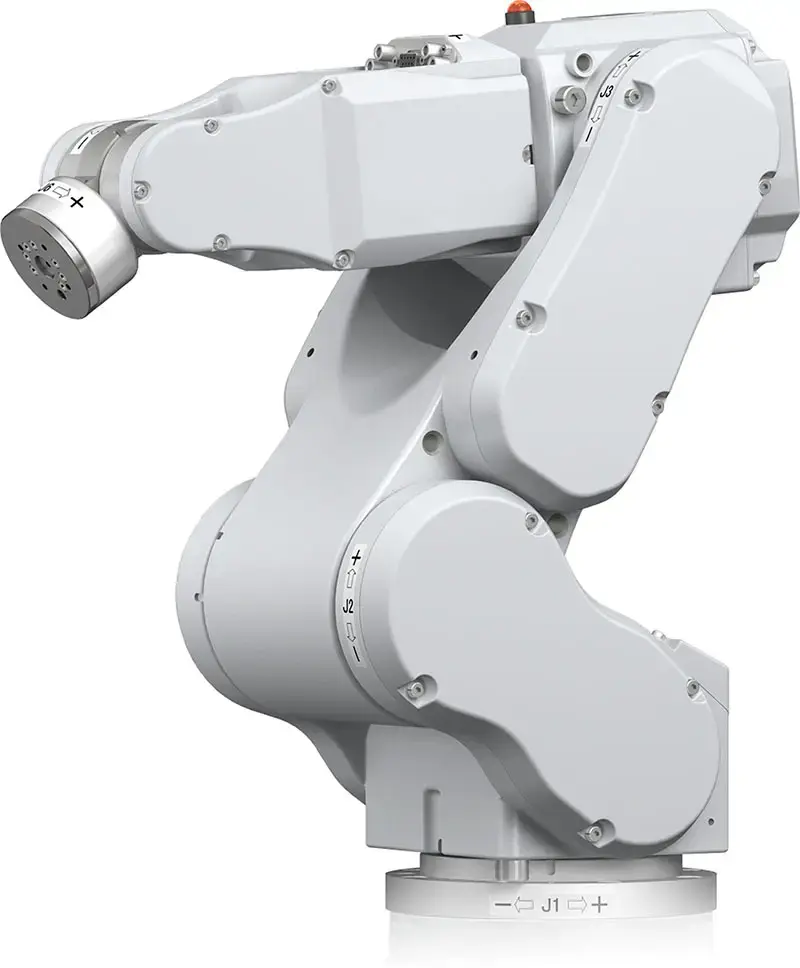

Looking for Automated Infeed Options?

To maximize the efficiency and speed of the 600 series flow wrapper, Viking Masek manufactures a variety of automatic infeed options. Whether you have multiple rows of product that need to move to single file, need your product placed into stacks, robotically placed onto the infeed, or something completely custom, Viking Masek will create a solution to fit your production needs, space allowed, and labor reduction needs.

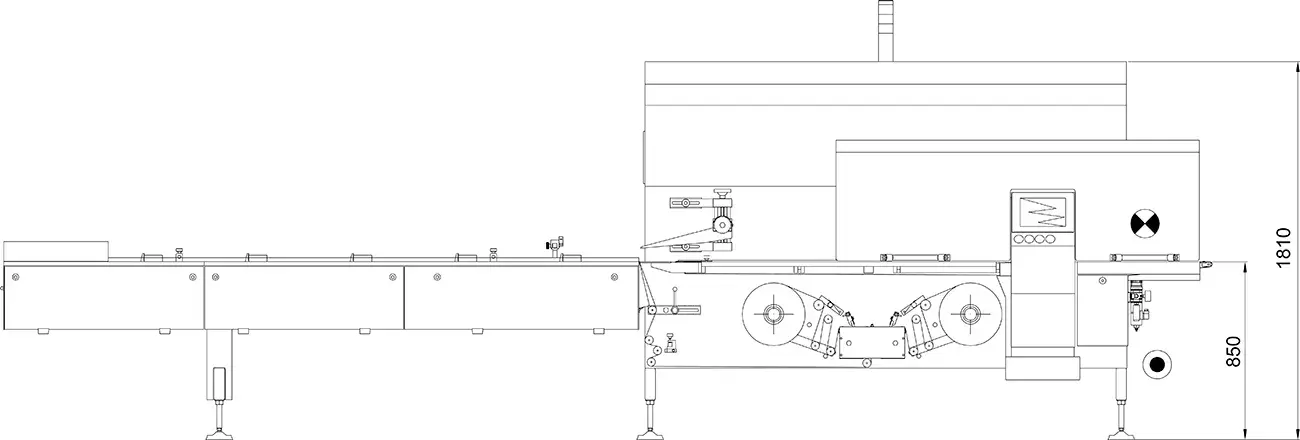

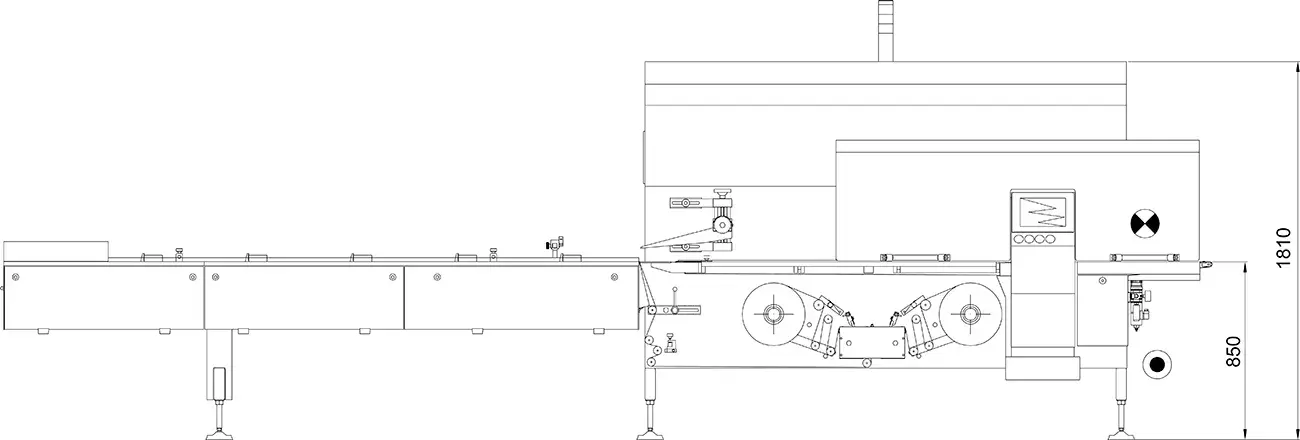

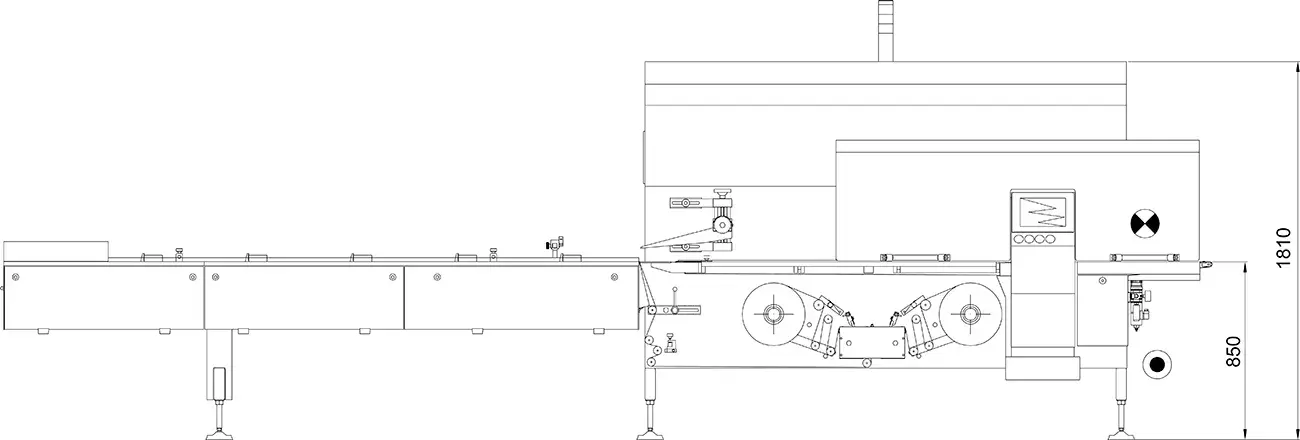

Specifications

| Bag width | 10 - 406 mm (0.39" - 16") |

|---|---|

| Bag length | 50 - 550 mm (1,96" - 21,65") |

| Weight | 1000 - 1500 kg (2205 - 3307 lb) |

| Air pressure | 6 bar (15–18 CFM at 90 PSI) |

| Power supply | 380-440 VAC / 3 Ph / 50-60 HZ |

Features

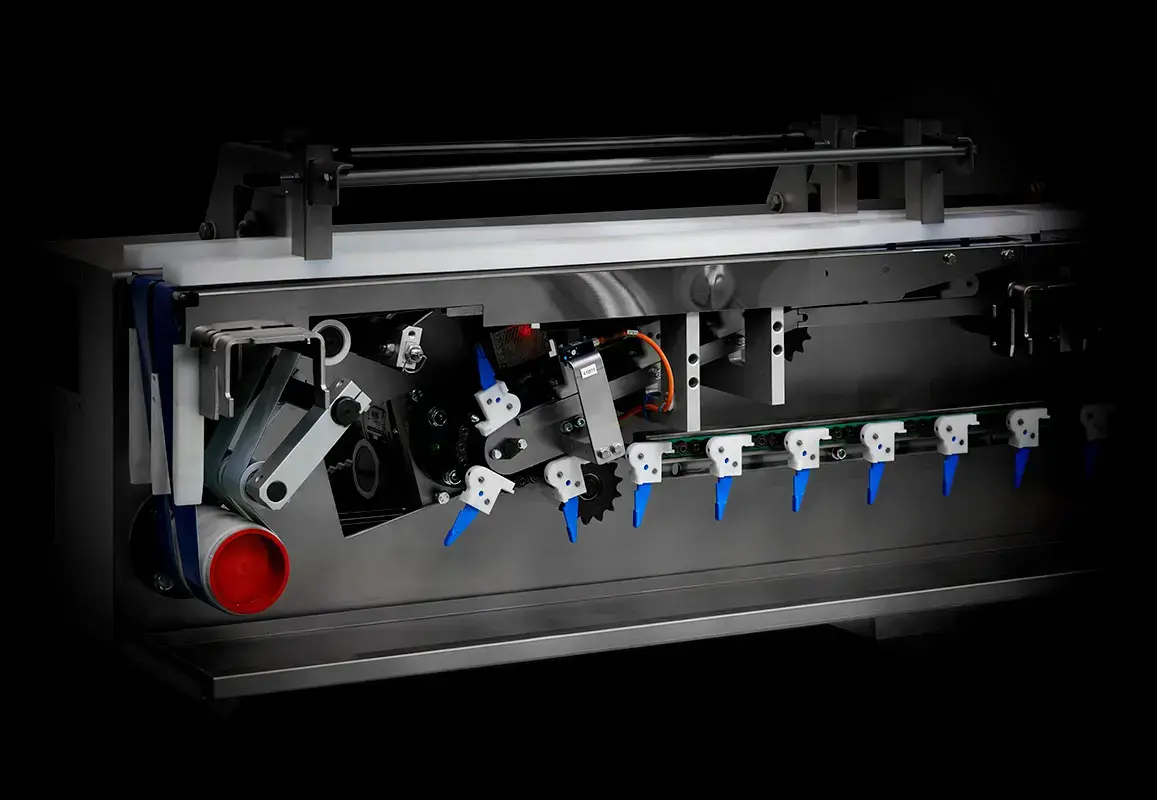

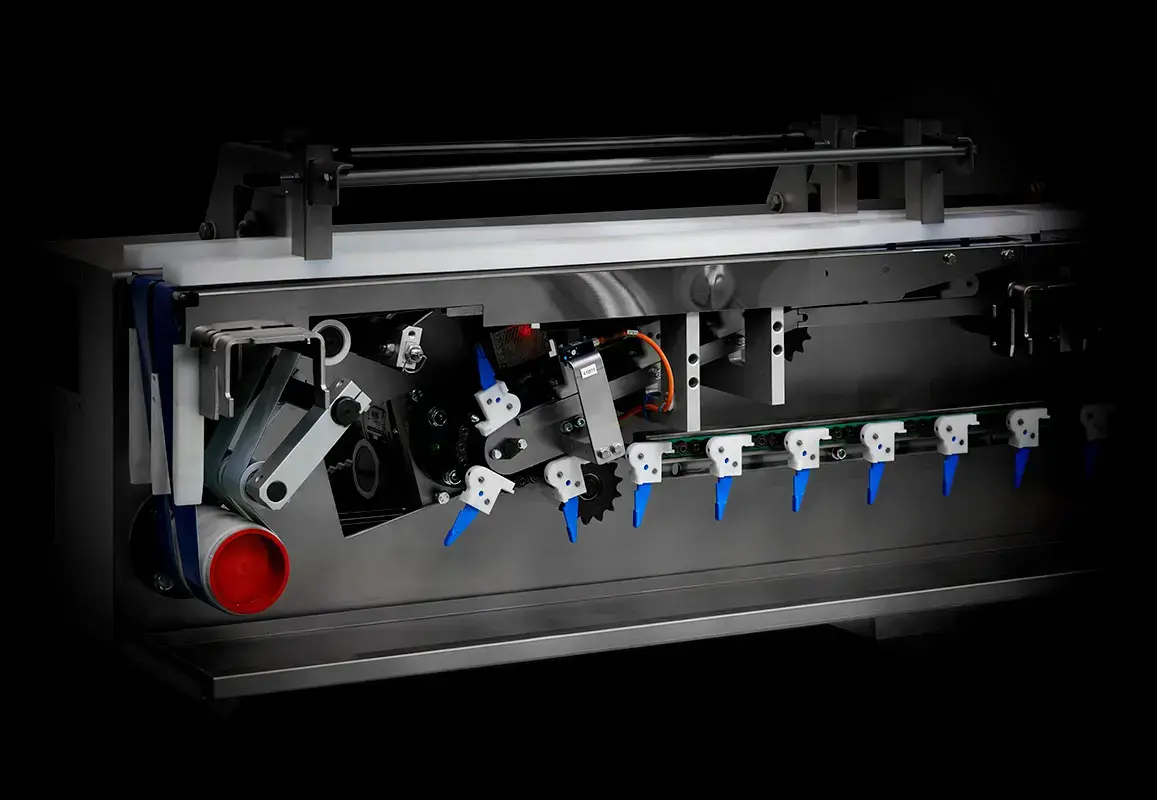

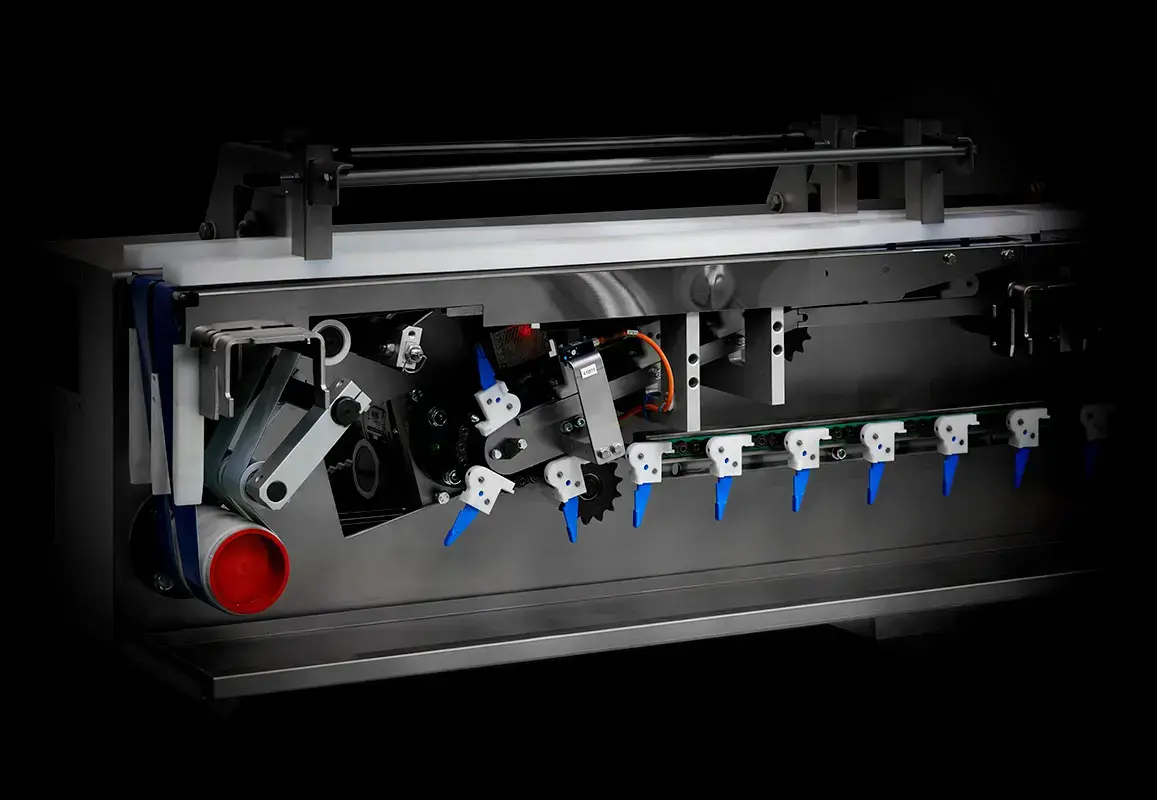

- Pusher conveyor

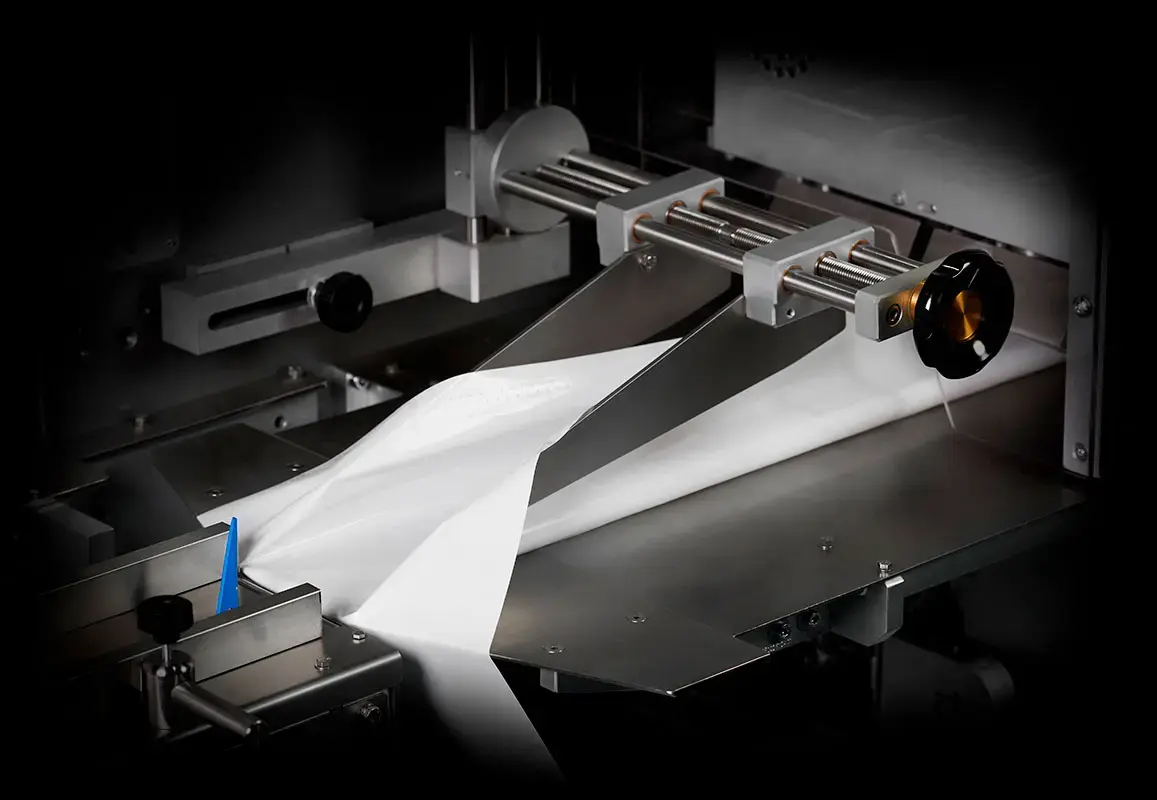

- Bottom reel holder

- Universal forming box

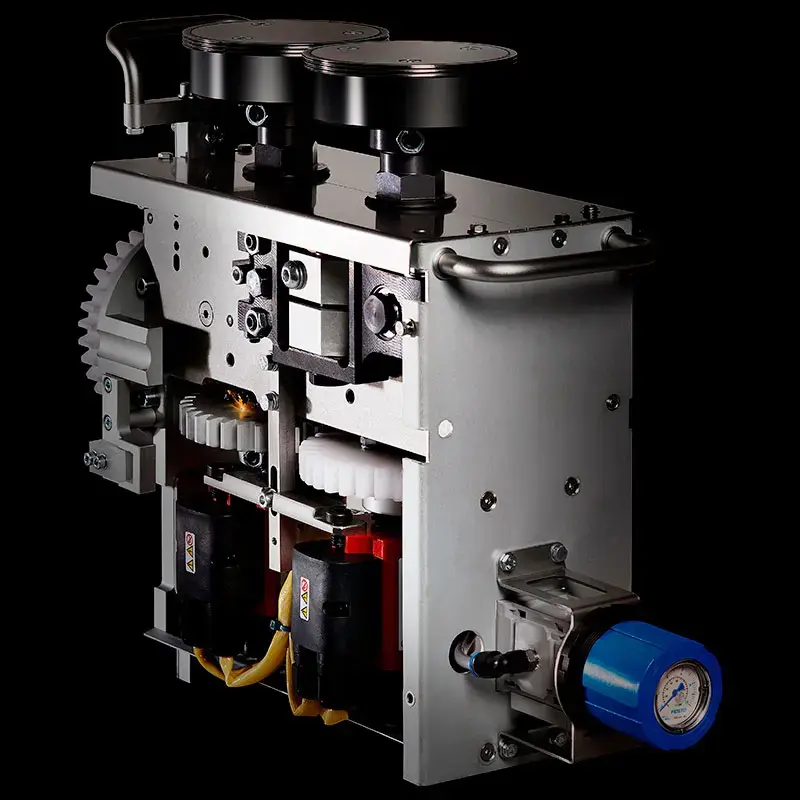

- Fin longitudinal sealing unit

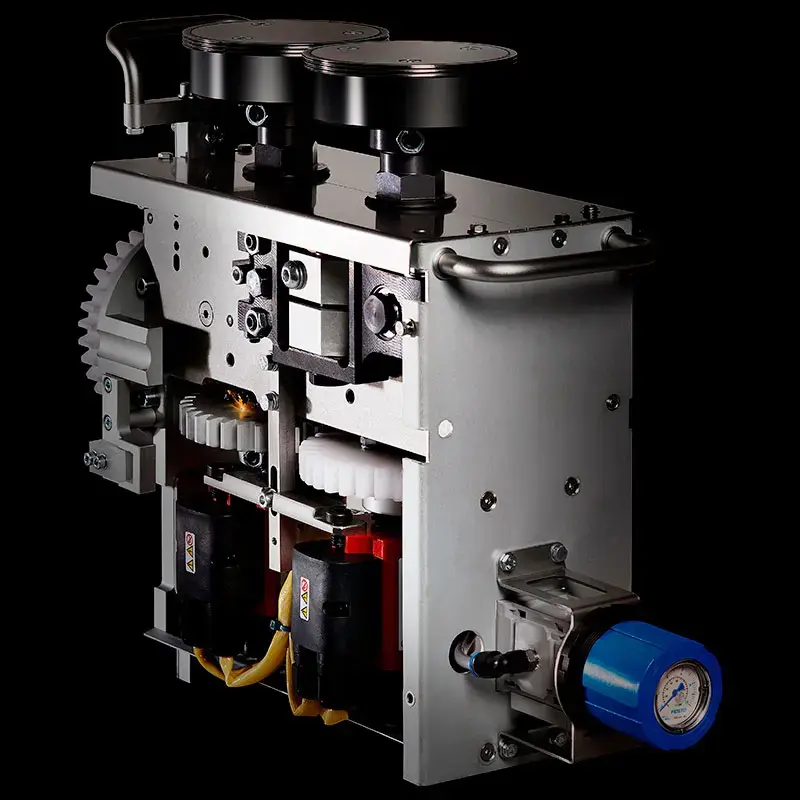

- End cutting and welding unit

- Longitudinal welding module

- Outfeed conveyor

- Transmission cabinet

- 10.4” Touch Screen (HMI)

- Easy changeover

- Modular construction

- Minimal maintenance requirements

- Automatic film splice

- Robust stainless steel build

Max Speed

500 bpm

Bag Size

Min 10 x 50 mm (0.39" × 1.96")

Max270 × 550 mm (10.2" × 21.65")

Compatible Applications

Food & Beverage

Health & Medical

Options

- Poly configuration for polyethylene films

- Cold configuration for cold sealing films

- Box Motion configuration for hermetic sealing

- Robotic handling for right hand execution

- Integration with feeders

- Integration with ancillary equipment

Related Machines

Let’s Talk

Exploring automation for the first time? Looking to simplify or expand a current system? Our team is here to help! No pressure — just a real-world conversation focused on what matters most to your business.