Optimizing packaging efficiency: The role of Flow Wrapping Machines in integrated systems

By Danielle Ohl on July 29, 2024

In the world of packaging, making things faster and more efficient is always a win.

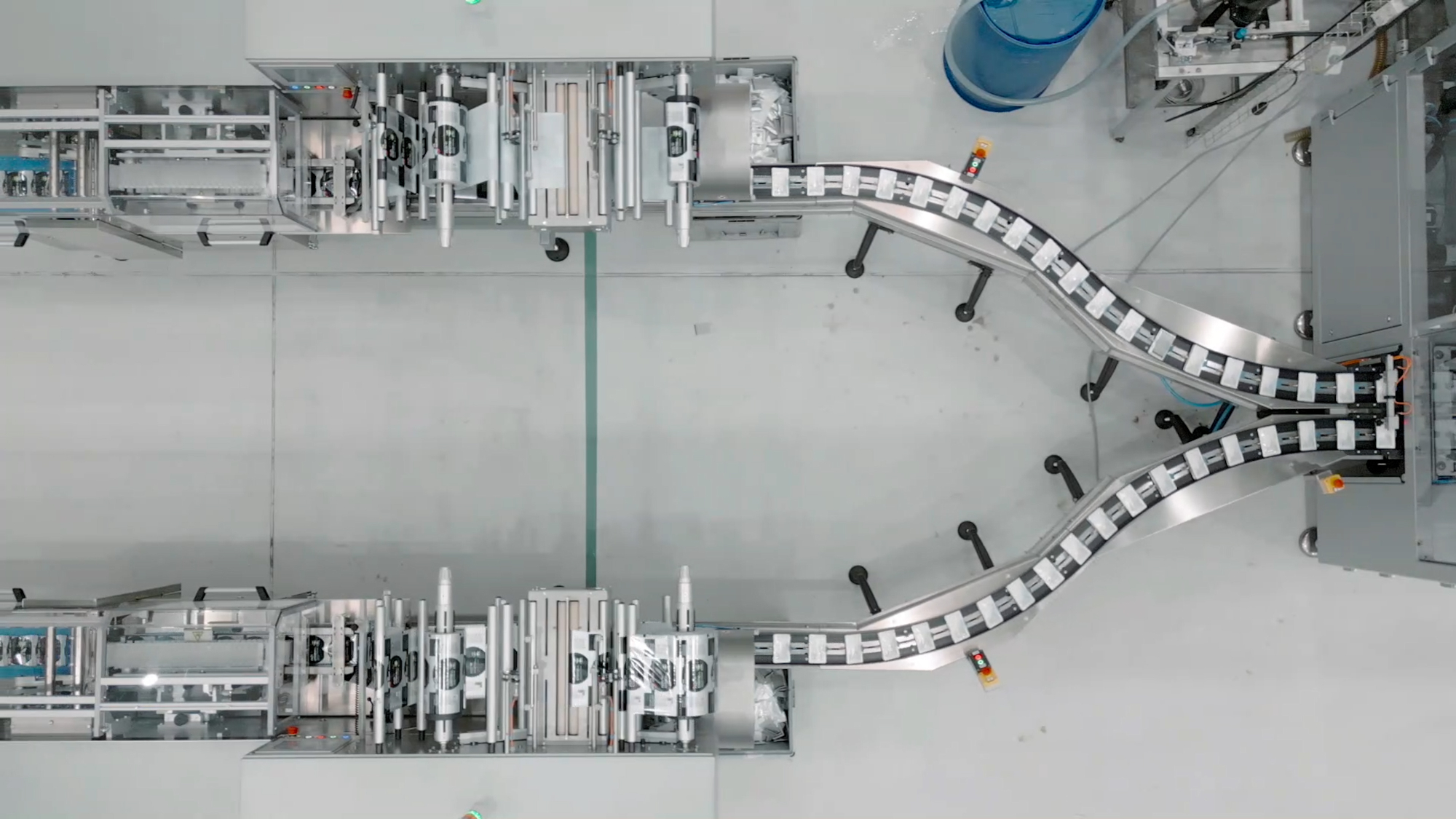

That's where flow wrapping machines come in. These machines are like the superheroes of the packaging line, quickly wrapping products in a sleek film to keep them fresh and looking great on the shelf.

Whether it's food products, consumer goods, or pharmaceuticals, flow wrapping machines get the job done quickly and neatly. But the magic really happens when you team them up with other packaging equipment, turning your production line into a smooth-running operation.

Understanding Flow Wrapping Machines

Flow wrapping machines are used to package products in a horizontal motion, wrapping them in a protective film. They are ideal for packaging items in the food, medical, pharmaceutical, and consumer products industries.

Here's how they work: After the product is fed into the horizontal flow wrapping machine, the equipment beings to wrap a (usually plastic) film around the product, where the edges of the film are brought together to form a tube shape and sealed longitudinally. The wrapped product is conveyed horizontally to a sealing area where a bar seals the package shut, creating the bag's top and bottom seams. During this sealing process, the film is also cut to create individual packages. This method is efficient, maintains product freshness, and provides an appealing presentation.

Benefits of packaging equipment integration

While a flow wrapping machine can be the hero of your packaging line on its own, integrating it with other automated packaging machines can result in even greater efficiencies and higher profits for your business.

Packaging equipment commonly integrated with flow wrapping machines include:

- Carton and case packing machines. After your product is packaged on a flow wrapping machine, it can be transported downstream to automated carton or case packaging equipment that counts individual packages and packs them into boxes.

- Stick packaging machines. After your powder or liquid products are packaged on a stick pack machine, the packs can be conveyed to the flow wrapping machine where they are wrapped in an outer film. This process is ideal for bulk packaging or multi-packs of sticks.

- Vertical form fill seal (VFFS) machines. After your product is packaged on a flow wrapping machine, it can be transported to a vertical form fill seal machine and placed into bags in specific quantities. Another VFFS integration alternative is packaging products like coffee into filter bags on a VFFS machine and conveying the filter bags to a flow wrapping machine where they are wrapped in an outer film.

- Premade pouch machines. After your product is packaged on a flow wrapping machine, it can be transported to a premade pouch machine and placed into preformed bags in specific quantities.

- Another flow wrapping machine. After your product is packaged on a primary flow wrapper, the finished packs can be counted and collated, and then transported to a secondary flow wrapping machine for a final outer wrap.

- Custom solutions. Many types of automated packaging equipment can be combined to create a custom solution to meet your unique needs. For example, a salad kit could begin its life on VFFS machine where the individual components are packaged. Those components can then be counted, collated, and fed into a flow wrapping machine for an outer wrap, and then transported to another VFFS machine to complete the final salad kit product.

Steps for successful integration

Before considering integrating a flow wrapping machine with other packaging equipment, we recommend doing some serious vetting of potential machine manufacturers to find one that matches your needs and values. The supplier you choose should see you as a long-term partner and not just a number.

Viking Masek is a single-source provider of automated packaging systems. This means we source, quote, sell, integrate, and support each piece of your packaging system. We follow a Proven Partnership Process that prioritizes the needs of the client above all. The most important steps of our partnership and integration process are:

- Assess current packaging line: Viking Masek evaluates your existing equipment and processes to identify areas where integration can add value.

- Consult with experts: Viking Masek’s team designs a customized solution that fits your specific operational needs. Our experts can provide insights into machine compatibility, layout design, and system optimization.

- Implement technology solutions: We utilize advanced software and control systems that allow different machines to communicate and operate cohesively. This includes synchronization of speeds, coordination of material handling, and centralized monitoring.

- Training and support: Viking Masek’s team will ensure that your staff are adequately trained to operate and maintain your integrated packaging system. We provide crucial ongoing support for troubleshooting and optimization of system performance.

- Continuous evaluation and improvement: Through a Preventive Maintenance program, Viking Masek’s team regularly reviews the integrated packaging line’s performance to identify opportunities for further improvement.

Learn more about flow wrapping machine integration

Flow wrapping machines are game-changers in the packaging world, offering speed, efficiency, and a polished look for your products. By integrating these machines with other packaging equipment, you can create a seamless, simplified operation that boosts productivity and profitability.

Whether you're packaging food, consumer goods, or pharmaceuticals, the benefits of flow wrapping machines are clear. As you explore ways to enhance your packaging process, consider the power of integration and how it can transform your business. With the right setup, you’ll not only keep your products fresh and appealing but also streamline your entire operation.

Want to chat with a flow wrapping machine integration expert? Request a consultation today.

Request a free consultation >>Related Posts

Introducing Viking Masek's advanced flow wrapping equipment

Packaging Your Morning Pick-Me-Up