Overview

M250 VFFS Machine Packages Liquids and Dusty Products

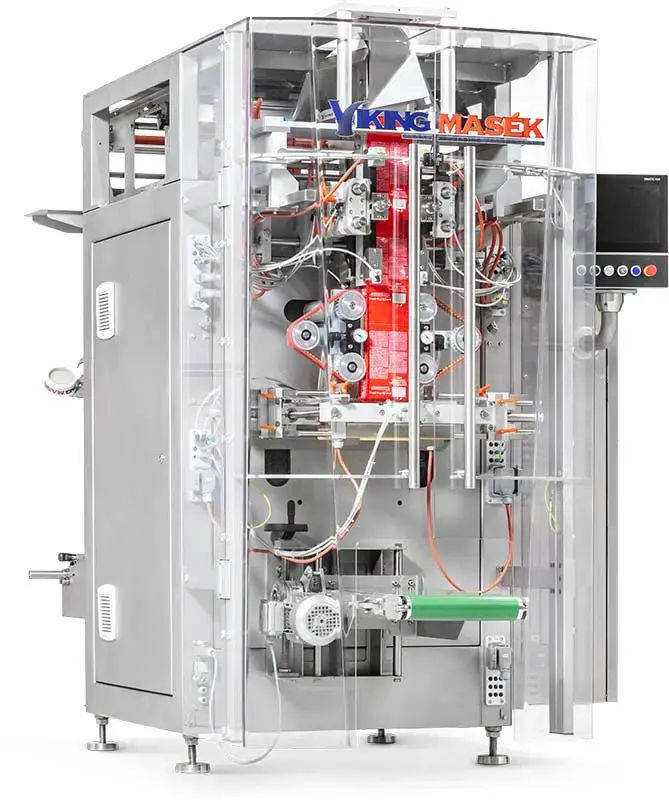

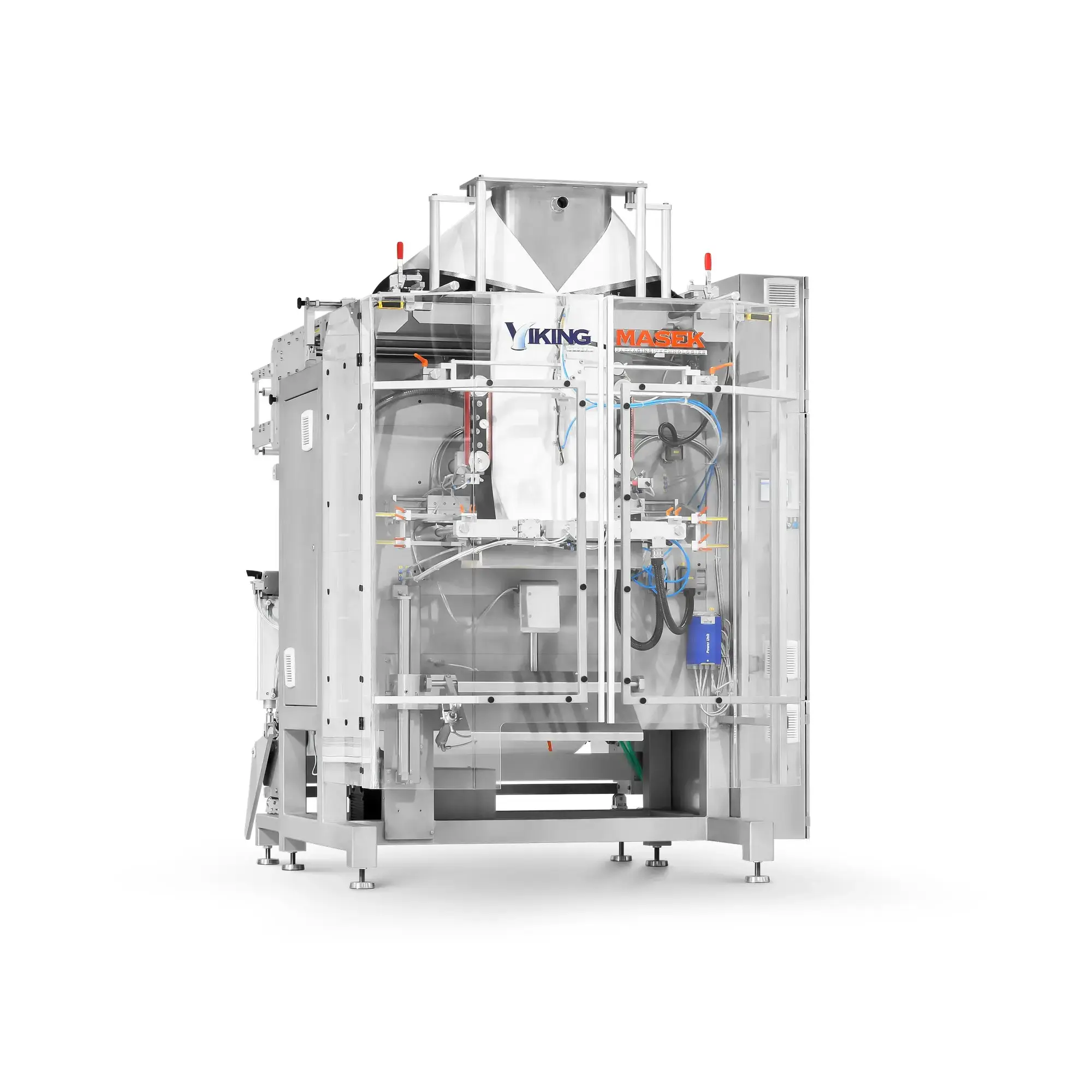

The rugged and reliable M250 VFFS bagger is designed for packaging in dusty, wet, or washdown-sensitive conditions. With an enclosed jaw drive and stainless steel frame, this versatile machine handles both solids and liquids, making it a top choice for coffee, cereal, cannabis, and more. Optional washdown construction ensures compliance with stringent food safety standards.

Key Features

- High-performance solution for dusty and wet environments

- Capable of packaging both solids and liquids

- Ideal for coffee, cereal, cannabis, and similar products

- Optional washdown build meets food safety cleaning requirements

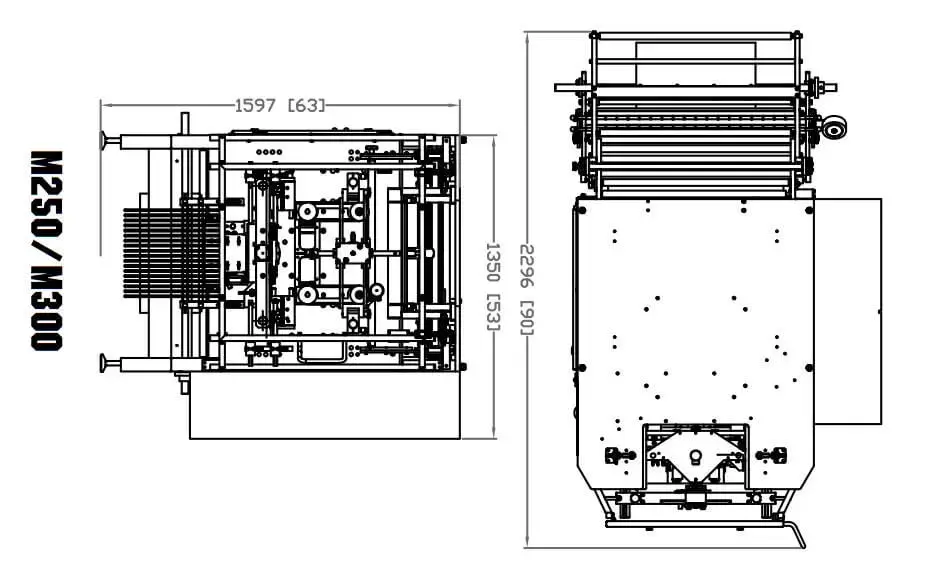

Specifications

| Maximum Roll Diameter | 500 mm (19.6") |

|---|---|

| Maximum Roll Width | 545 mm (21.4") |

| Weight | 750 kg (1,655 lbs) |

| Air Requirements | 6 bar (15-18 CFM at 90 PSI) |

| Power Supply | 6 kVA (480 V, three phase, 60 Hz., 20 AMPS) |

Features

- Robust stainless steel frame

- Enclosed, direct drive jaw actuation

- Siemens or Allen Bradley control

- Off-the-shelf components

- Minimal maintenance requirements

- Short film path

- Small machine footprint

- No tool change-over

- Self-centering pull belts

- Automatic film tracking

- VFD powered film unwind

- Quick film splice table

- Product stagers

- End-seal cooling air

- Bag deflators

- Photo-eye and encoder

- Tri-fold guard door

- Jaw obstruction detection

- Runs most film structures

- Storage for 100 product recipes

- Intuitive touch screen human interface (HMI)

Max Speed

140 bpm

Bag Size

Min 60 mm x 60 mm (2.3" x 3.1")

Max250 mm x 400 mm (9.8" x 15.75")

Compatible Applications

Food & Beverage

Health & Medical

Options

- Bag-in-bag configuration

- Flat bottom bag assembly

- Horizontal jaw for up to 340 mm (13.39") wide bag

- Impulse sealing for poly film structures

- Washdown IP66 construction

- Vacuum pull belts

- Hole punch (Euro slot or round)

- Fold-down/tape-down unit

- Load shelf

- Product settler

- Gas flush

- Static elimination

- Degassing valve applicator

- Tear notch

- Remote diagnostics

- In-feed and take-away conveyors

- Zipper applicator

- Integration with variety of fillers, printers, metal detectors, label applicators, and checkweighers

Let’s Talk

Exploring automation for the first time? Looking to simplify or expand a current system? Our team is here to help! No pressure — just a real-world conversation focused on what matters most to your business.