Overview

Effortless Large Bag Packaging with M500 VFFS Machine

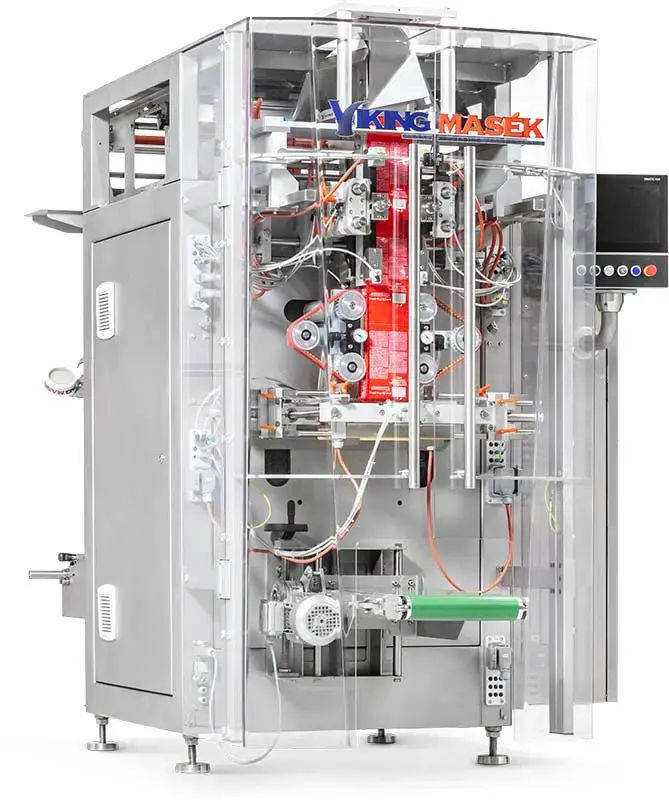

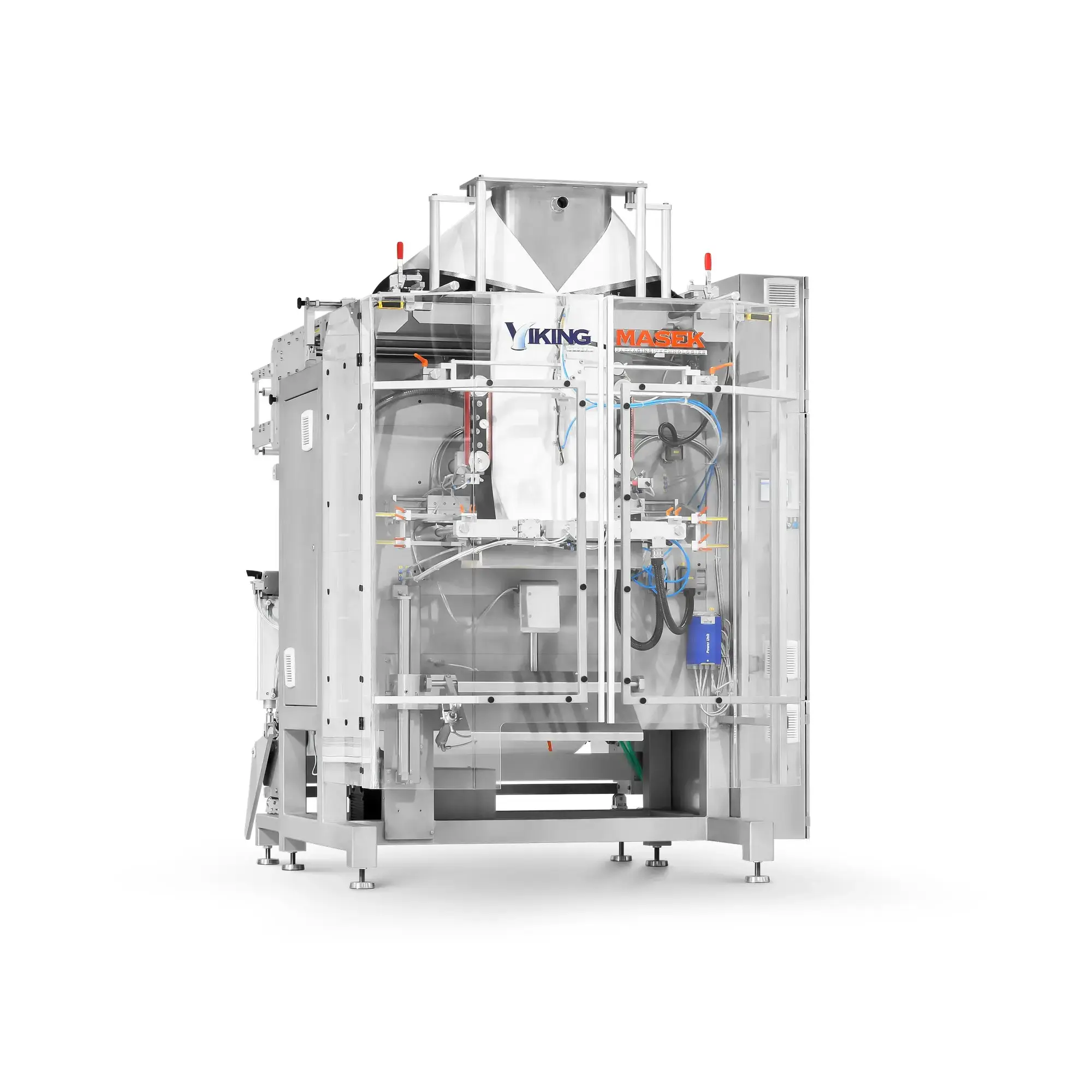

The M500 is a versatile, operator-friendly VFFS machine engineered for large bag packaging. Ideal for dusty products and built for low maintenance and maximum uptime, it forms premium quad seal, flat bottom, and stand-up bags with ease. Designed to reduce downtime and cost while delivering exceptional shelf appeal, the M500 is a high-efficiency solution for businesses that demand both performance and presentation.

Key Features

- Designed for large-format bags, including quad seal, flat bottom, and stand-up styles

- Capable of adding zippers, tear notches, perforations, and carry handles

- Operator-friendly with minimal maintenance needs

- Produces custom bags at a fraction of the cost of premade alternatives

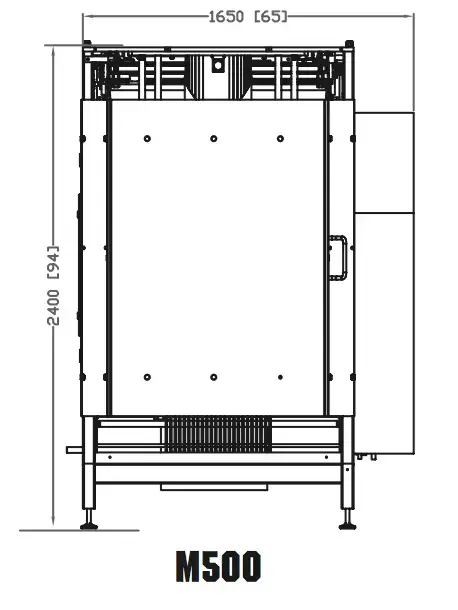

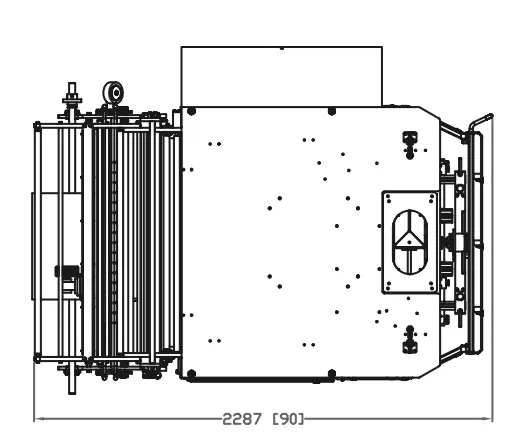

Specifications

| Maximum Roll Diameter | 500 mm (19.6") |

|---|---|

| Maximum Roll Width | 1,030 mm (40.5”) |

| Air Requirements | 12-18 SCFM @ 90 PSI w/o vac |

| Power Supply | Standard 208-240V, single phase, 60 Hz., 20 AMPS |

Features

- Robust, stainless steel frame

- Mechanical direct drive jaw actuation

- Off-the-shelf components

- Minimal maintenance requirements

- No tool changeover

- Self-centering pull belts

- VFD powered film unwind

- Quick film splice table

- Product stagers

- End-seal cooling air

- Bag deflators

- Photo eye and encoder

- Automatic film tracking

- Jaw obstruction detection

- Siemens or Allen Bradley controls

- Storage for 100 product recipes

- Intuitive touch screen human interface (HMI)

Max Speed

70 bpm

Bag Size

Min 150 mm x 100 mm (5.91" x 3.94")

Max500 mm x 600 mm (19.68" x 23.62")

Compatible Applications

Options

- Quad seal bag assembly

- Bag-in-Bag configuration

- Flat bottom bag assembly

- Washdown construction

- Vacuum pull belts

- Automatic film tracking

- Fold-down/tape-down unit

- Hole punch (Euro slot and round)

- Load shelf

- Product settler

- Gas flush

- Static elimination

- Degassing valve applicator

- Tear notch

- Remote diagnostics

- In-feed and take-away conveyors

- Integration with variety of fillers, printers, metal detectors, label applicators, and checkweighers

Let’s Talk

Exploring automation for the first time? Looking to simplify or expand a current system? Our team is here to help! No pressure — just a real-world conversation focused on what matters most to your business.