Overview

Simplify Packaging with the Compact, User-Friendly Viking-4SC-235

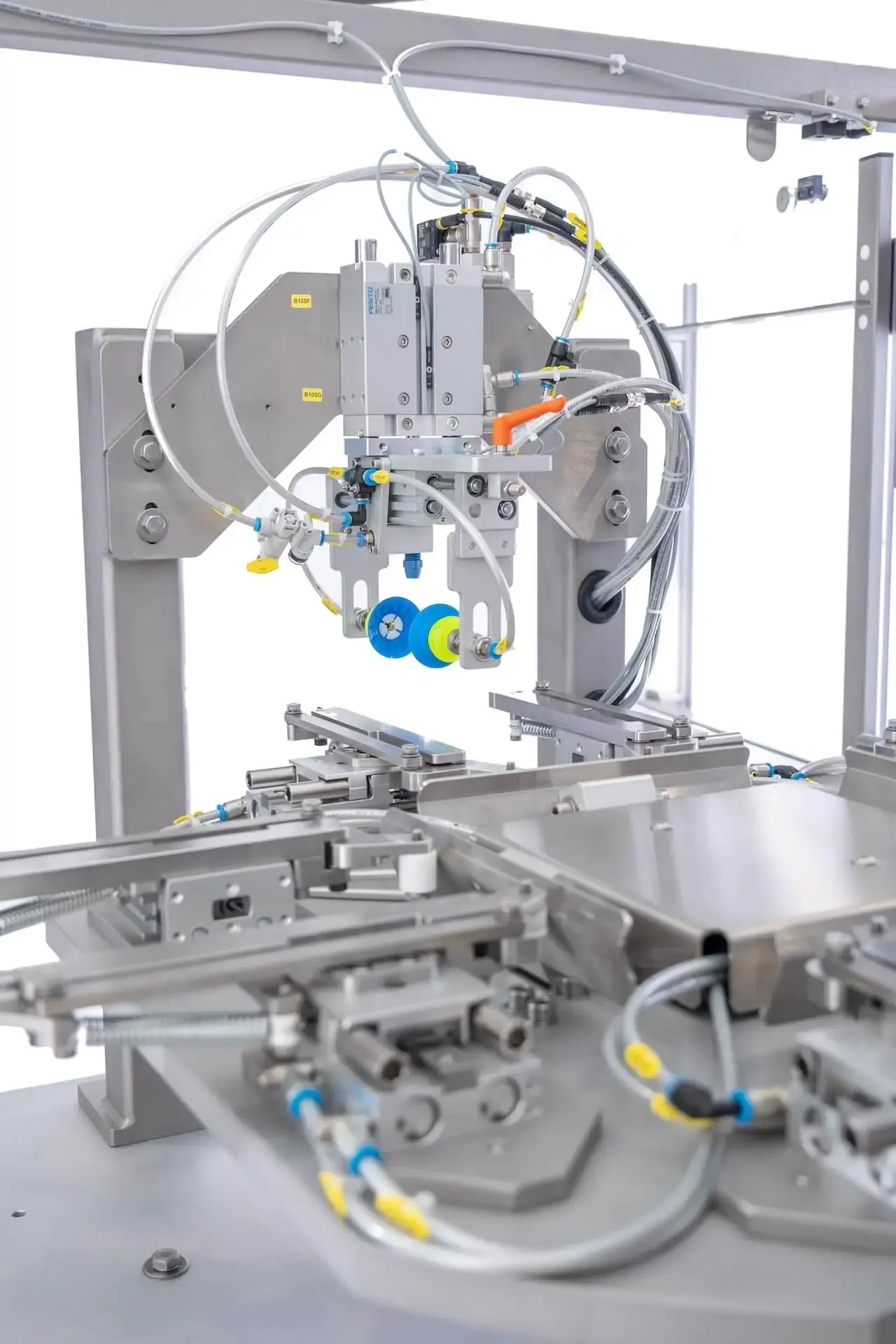

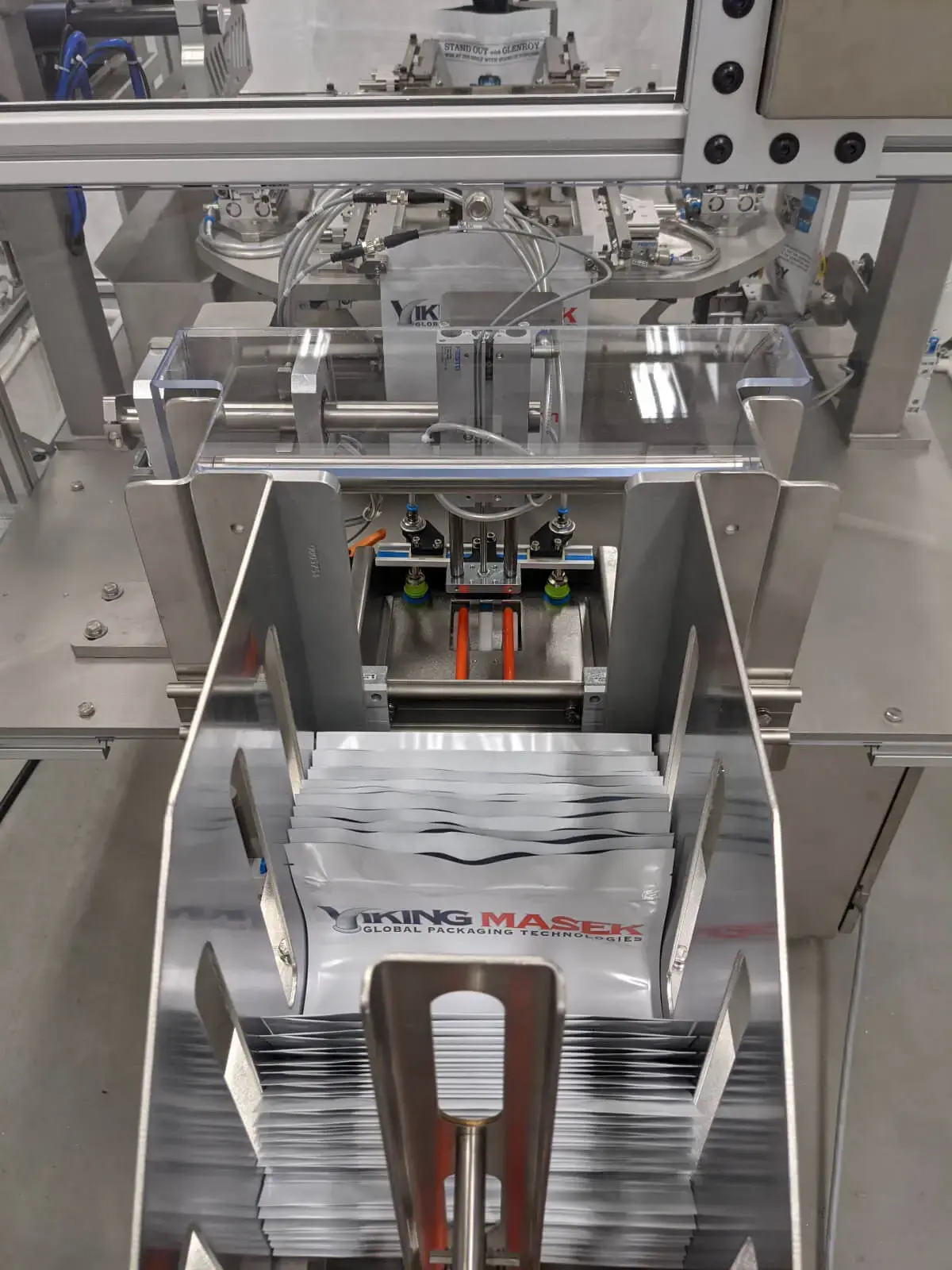

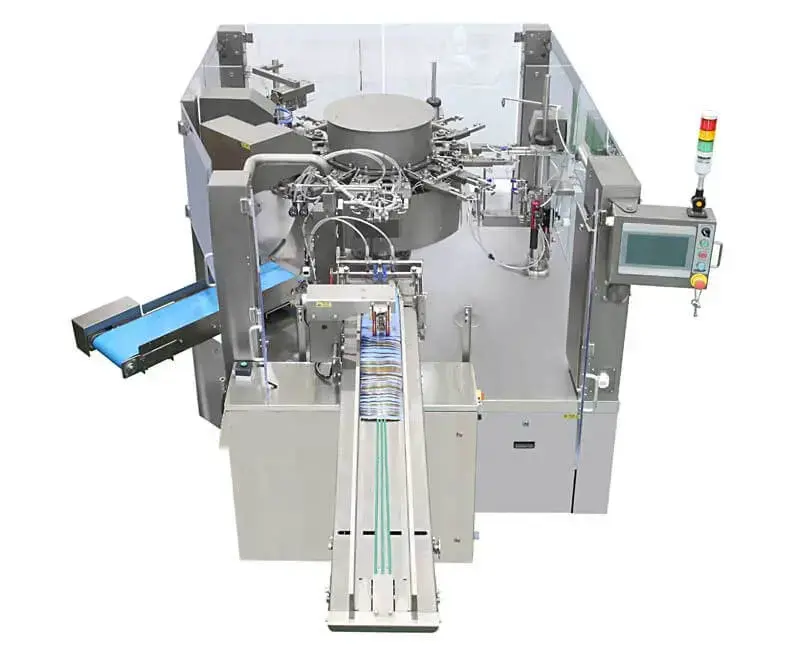

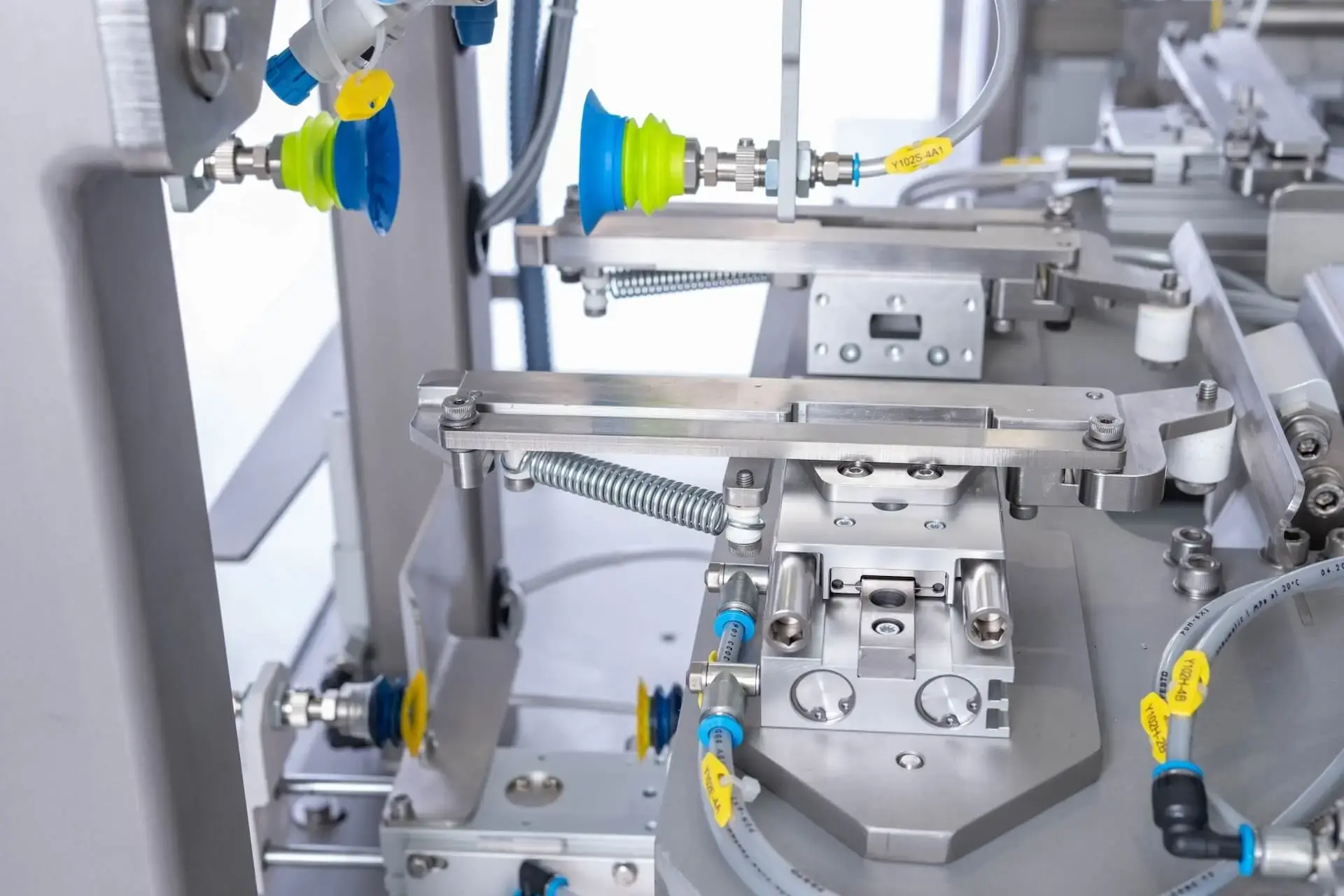

The Viking 4SC-235 is our most compact, user-friendly premade pouch machine, designed to simplify packaging for those new to automation. With a space-saving rotary design, intuitive touchscreen controls, and smart features like pouch presence detection and automated production memory, it’s the perfect entry point into efficient, modern packaging.

Key Features

- 4-station rotary system for single-bag operation

- Easy-to-use interface with 7" touchscreen and PLC control

- Stores production settings: gripper size, speed, temperature, volume

- No pouch, no fill, no seal logic for reduced waste

Specifications

| Number of Stations | 4 |

|---|---|

| Number of Lanes | 1 |

| Maximum Speed Per Minute (dry cycle) | 25 |

| Bag Gripping Range (mm) | 90-235mm |

| Maximum Bag Length (mm) | 508mm |

| Power Supply | 480V / 3 Ph / 60 Hz / 30 A) |

| Compressed Air | 20 cfm |

Features

- 4 stations, single bag

- Easy-to-use, simplified user experience

- Compact design

- PLC control with 7" touch screen operation

- Servo-driven Allen Bradley control platform

- Production parameter memory including gripper size, machine speed, sealing temperature, and filling volume

- Pouch presence detection – no filling, no sealing

- Food grade air filter for bag open air

- Intuitive touch screen human interface (HMI)

Max Speed

25 cpm

Bag Size

Min 90 mm W x 120 mm L

Max235 mm W x 508 mm L

Compatible Applications

Food & Beverage

Options

- Product filling – can be integrated with multi-head scales and auger fillers

- Zipper opening and/or closing

- Date coding

- Product settler

- Gas flush

- Discharge conveyor

- UL or CUL certification

- Accommodation of pouches with hole punch/tear notch

Let’s Talk

Exploring automation for the first time? Looking to simplify or expand a current system? Our team is here to help! No pressure — just a real-world conversation focused on what matters most to your business.