Overview

Custom Premade Pouch Machines that Align with Your Industry

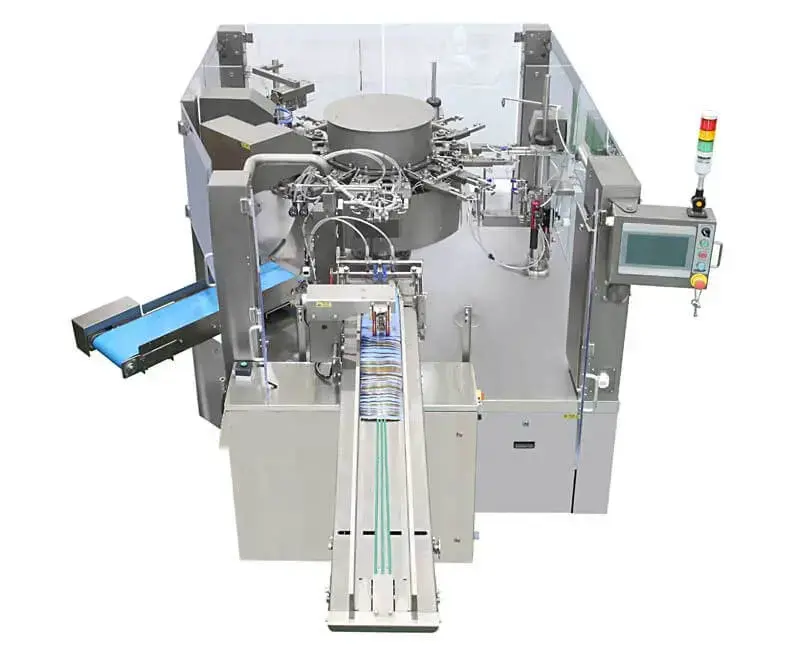

The Viking 8S-350 is a customizable rotary premade pouch machine built to meet the needs of various industries — from powders to food products. Capable of filling and sealing bags up to 350 mm wide at speeds of up to 50 cycles per minute, this 8-station solution offers advanced automation, flexibility, and clean, reliable sealing for high-performance pouch packaging.

Key Features

- 8-station rotary platform for single-bag production

- Stores production parameters: gripper size, speed, sealing temp, fill volume

- Deoxidizer feeding station included for freshness-sensitive products

- Integrates with multi-head scales, auger, or volumetric fillers

Specifications

| Number of Stations | 8 |

|---|---|

| Number of Lanes | 1 |

| Maximum Speed Per Minute (dry cycle) | 50 |

| Bag Gripping Range (mm) | 160-320mm |

| Maximum Bag Length (mm) | 420mm (500mm with extender) |

| Power Supply | 6480 V / 3 Ph 50/ 60 Hz / 35 A |

| Compressed Air | 21 cfm |

Features

- 8 station, single bag

- PLC control with touch screen operation

- Highly durable welded steel frame

- Production parameter memory including gripper size, machine speed, sealing temperature, and filling volume

- Pouch presence detection – no filling, no sealing

- Bag deflation with wire guide or push bars

- Automatic deoxidizer feeding station

- Product filling – can be integrated with multi-head scales, volumetric fillers and auger fillers

- Two step sealing process guarantees clean sealing

- Cooling station for liquid products

- Intuitive touch screen human interface (HMI)

Max Speed

50 bpm

Bag Size

Min 160 mm W x 150 mm L

Max320 mm W x 420 mm L

Compatible Applications

Food & Beverage

Health & Medical

Options

- Proprietary Viking robotic pick & place bag infeed system

- Product filling – can be integrated with multi-head scales, volumetric fillers and auger fillers

- Fully interlocked safety guards

- Pre Sealing station for liquid or paste

- Zipper opening device

- Clean-in-place design

- Long raised rotary shaft extender for longer bags

- Extended bag magazine

- Date coding: emboss, hot stamp, inkjet or thermal transfer

- Quality control: checkweigher, metal detector, X-ray inspection

- Dust suction nozzles and dust collector

- Product settler

- Bag supporter for heavy fills

- Ethernet connectivity

- Washdown structure (IP65 or IP66)

- Steam or gas flush

- Rotary running clockwise model

- Bag rejection system

- Stand-up discharge

Let’s Talk

Exploring automation for the first time? Looking to simplify or expand a current system? Our team is here to help! No pressure — just a real-world conversation focused on what matters most to your business.