Find the Right Machine

Step One: What are you packaging?

Bakery

Candy

Cannabis

Food & Beverage

Cannabis

Health & Medical

Cereal, Nuts & Snacks

Cheese

Coffee

Fresh Fruit & Vegetables

Individual Quick Frozen (IQF)

Liquids

Meat, Poultry & Fish

Medical Devices & Supplies

Medical Testing Kits

Non-Food Products

Pasta, Beans & Rice

Pet Food & Treats

Pills & Capsules

Powders

Step Two: Choose Your Package

Flat Bottom

Pillow

Quad Seal

Stick Pack

Plow Down Tape Down

Premade Pouch

Three Side Seal

Four Side Seal

Standcap Pouch

Step Three: Choose Your container

Top Load Carton

End Load Carton

Sleeve

Tray

Wrap Around

1

Application

Coffee

2

Packaging

Premade Pouches

3

Container

Tray

Find the right machine

Your Solutions

Sorry, nothing matched your query. Our team is here and happy to help! Connect with our experts on your specific needs and we’ll help find the right solution together.

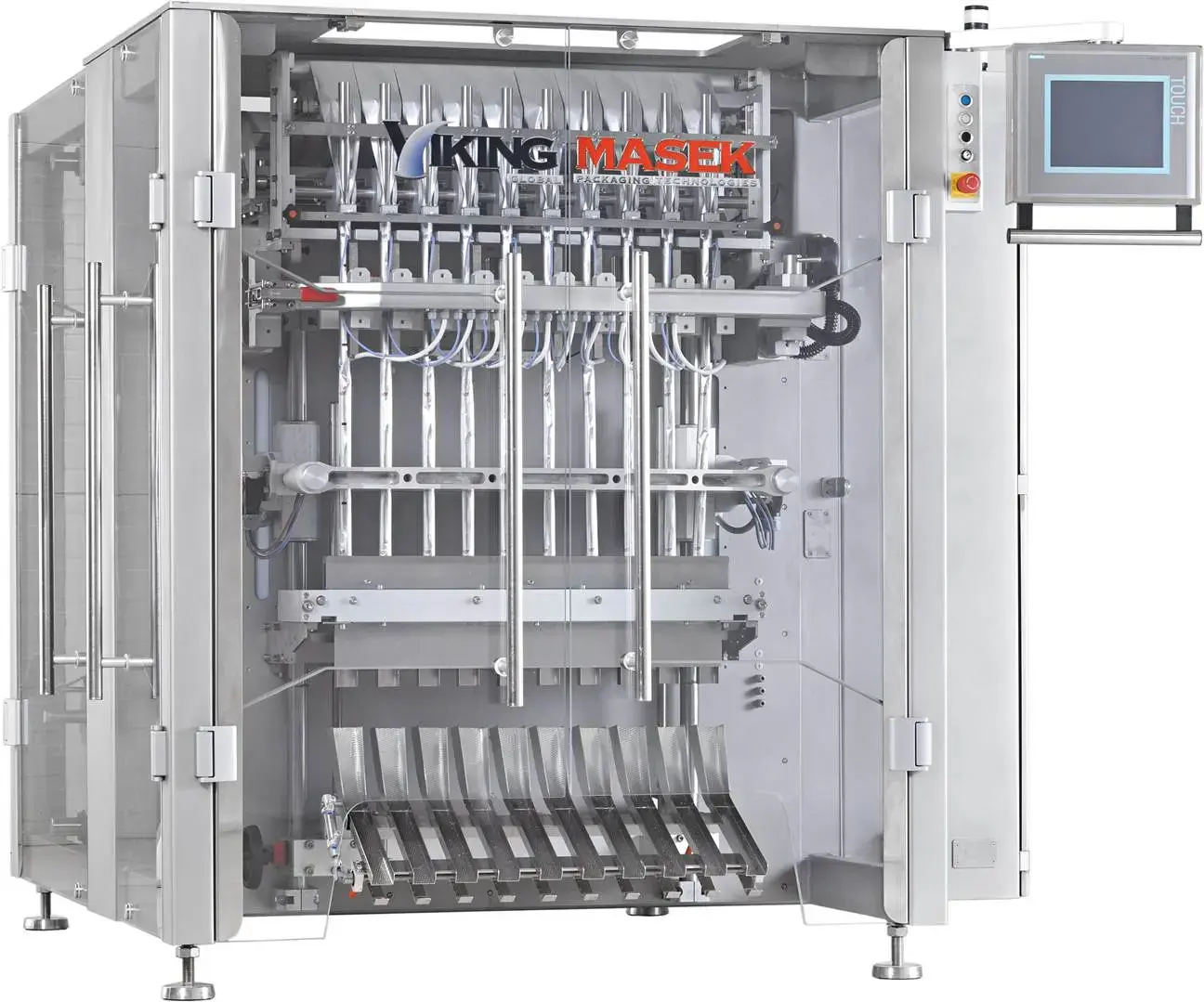

ST400

Stick Pack

Rugged ST400 multi lane stick pack machine for all product types, runs at speeds up to 50 cycles per minute.

ST600

Stick Pack

Servo-driven ST600 stick pack machine w/ available powder and liquid fillers for stick packs up to 60mm wide x 200mm long, at speeds up to 80 cycles per minute.

ST800

Stick Pack

Multilane, IQ/OQ compliant ST800 stick pack machine for packaging large runs of liquid or powdered pharmaceuticals, nutraceuticals, and cannabis/CBD products.

ST1200

Stick Pack

Large capacity, high performance ST1200 stick pack machine packages up to 20 lanes simultaneously, at speeds of up to 50 cycles per minute.

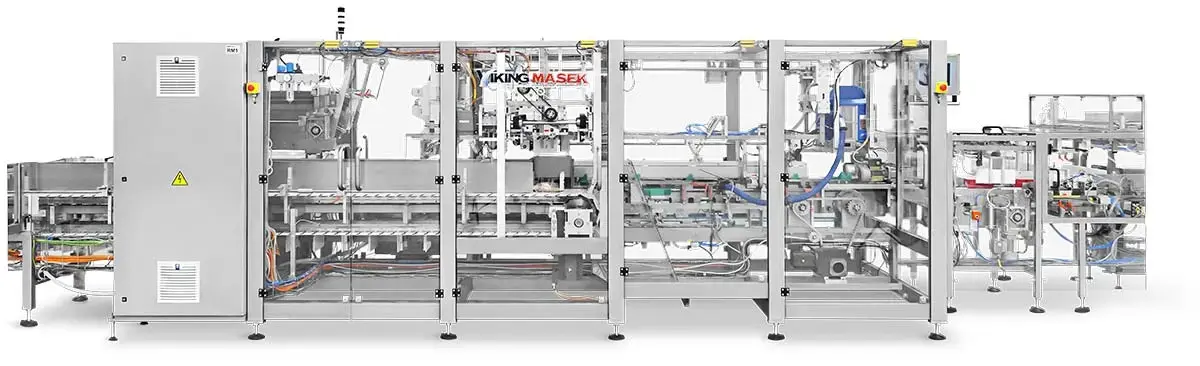

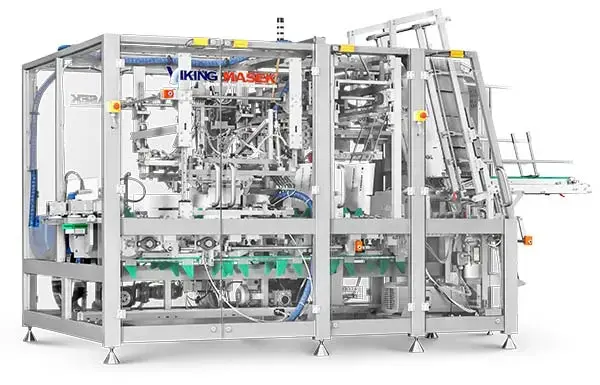

CAM

Cartoning & End-of-Line Automation

Servo-driven, stainless steel endload automatic cartoner with continuous or intermittent motion completes packaging machines.

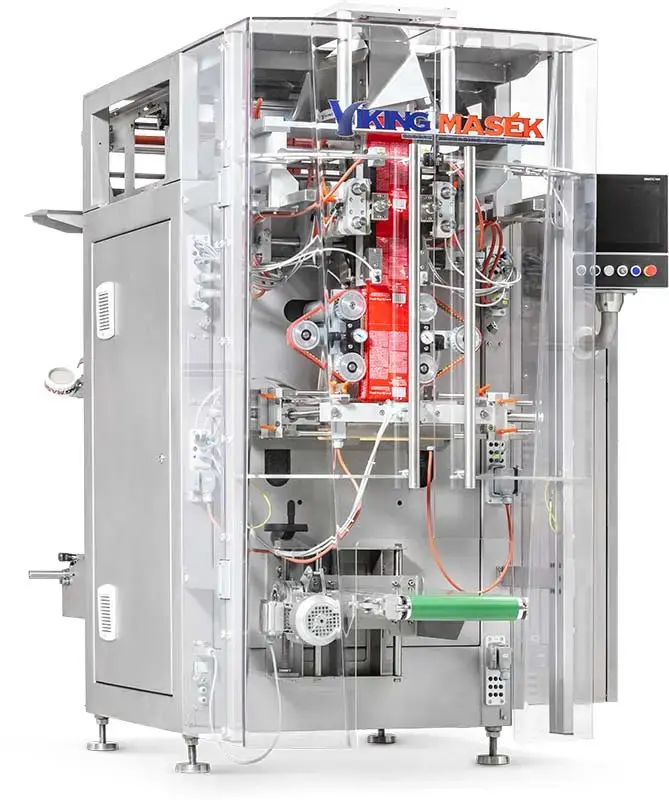

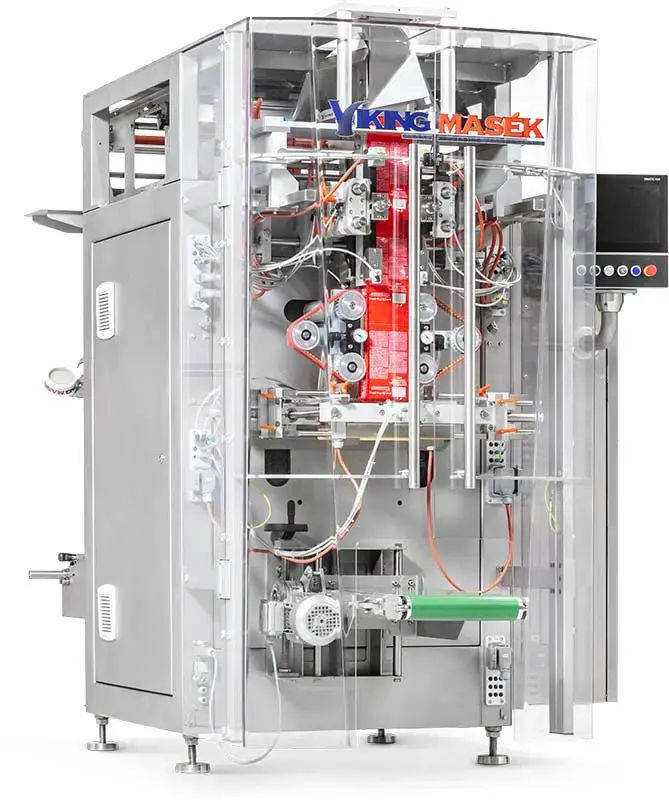

E300

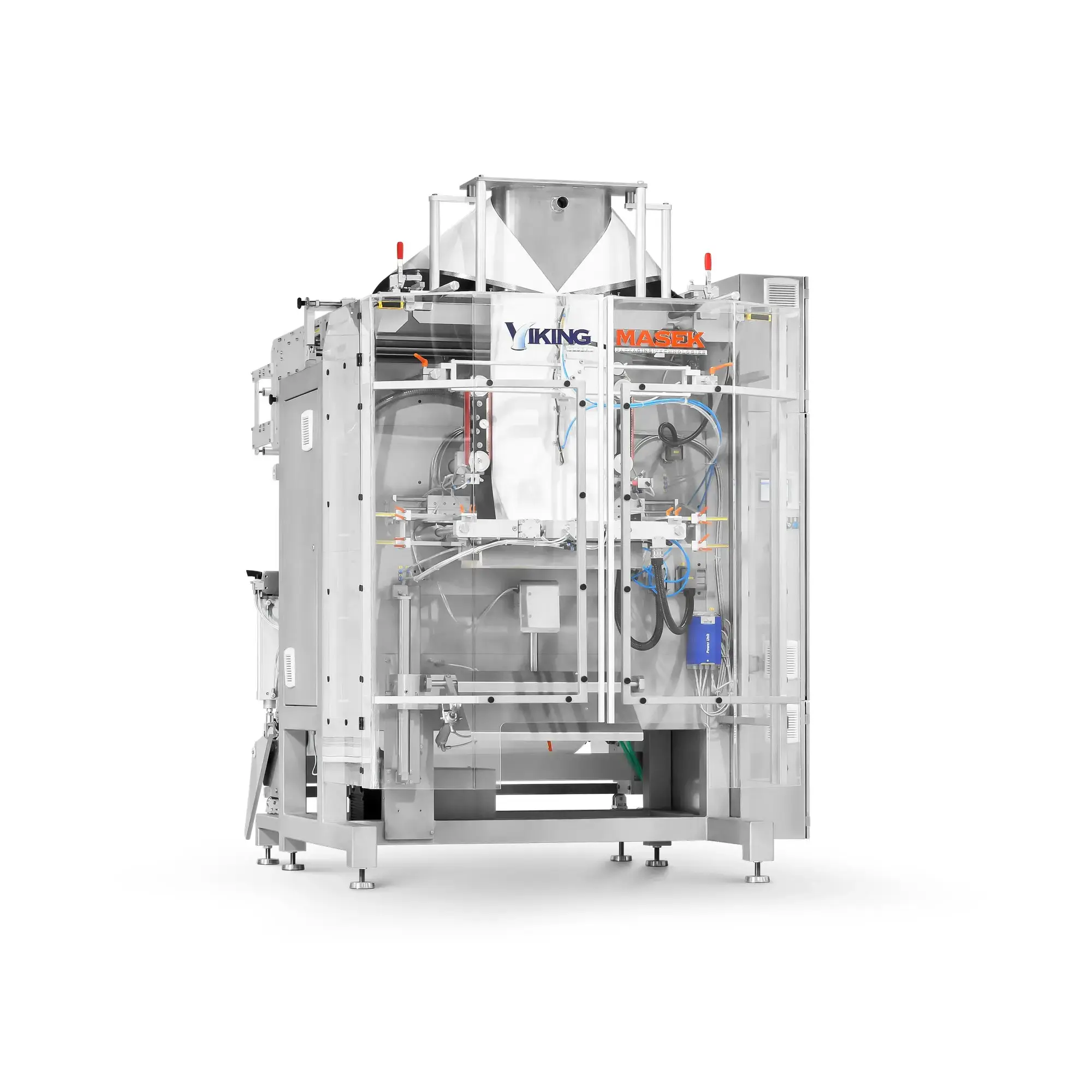

Vertical Form Fill Seal | Intermittent Motion

VFFS machine with a rugged stainless steel frame, servo drive, and minimal maintenance needs. Capable of bagging food and non-food products at up to 100 BPM.

ES400

Vertical Form Fill Seal | Intermittent Motion

Rugged, ultra-sanitary VFFS machine withstands the harshest washdown procedures to package fruit, vegetables, and fresh meats at speeds up to 60 BPM.

M250

Vertical Form Fill Seal | Intermittent Motion

Rugged M250 VFFS bagger with enclosed jaw drive is perfect for packaging in dusty or wet environments.

M250 BIB

Vertical Form Fill Seal | Intermittent Motion

Rugged bag-in-bag M250 BIB VFFS machine easily handles fractional packs of coffee, candy, or snacks at up to 100 cycles per minute.

M300c

Vertical Form Fill Seal | Continuous Motion

The M300c continuous motion VFFS machine combines robust, stainless steel design with packaging versatility, handling bags from 60mm to 300mm at 200 BPM.

M300i

Vertical Form Fill Seal | Intermittent Motion

Durability meets versatility in the stainless steel, closed frame M300i VFFS vertical bagger available in intermittent and continuous motion.

M400

Vertical Form Fill Seal | Intermittent Motion

Versatile M400 VFFS packaging machine for liquids, powders, and solids forms many bag styles and performs flawlessly in dusty or wet environments.

M500

Vertical Form Fill Seal | Intermittent Motion

Versatile, flexible VFFS packaging machine makes large, quad seal bags and is ideal for packaging dusty products.

S650

Vertical Form Fill Seal | Intermittent Motion

Rugged, stainless steel S650 VFFS machine with an enclosed servo-drive jaw offers versatile bulk bag packaging that stacks cleanly and easily onto pallets.

Liquid Sigma

Vertical Form Fill Seal | Continuous Motion

With a servo-driven airless fill squeegee sealing system, the Liquid Sigma 300 continuous motion bagger is designed to package liquids such as soups and sauces.

Velocity

Vertical Form Fill Seal | Continuous Motion

The Velocity is the fastest VFFS packaging machine in the world, running at speeds up to 300 BPM and handling package sizes up to 300mm wide.

Twin Velocity

Vertical Form Fill Seal | Continuous Motion

The world’s fastest continuous motion VFFS machine, the Velocity Twin bags snacks, coffee, and other dry goods at up to 540 BPM in package sizes up to 145mm.

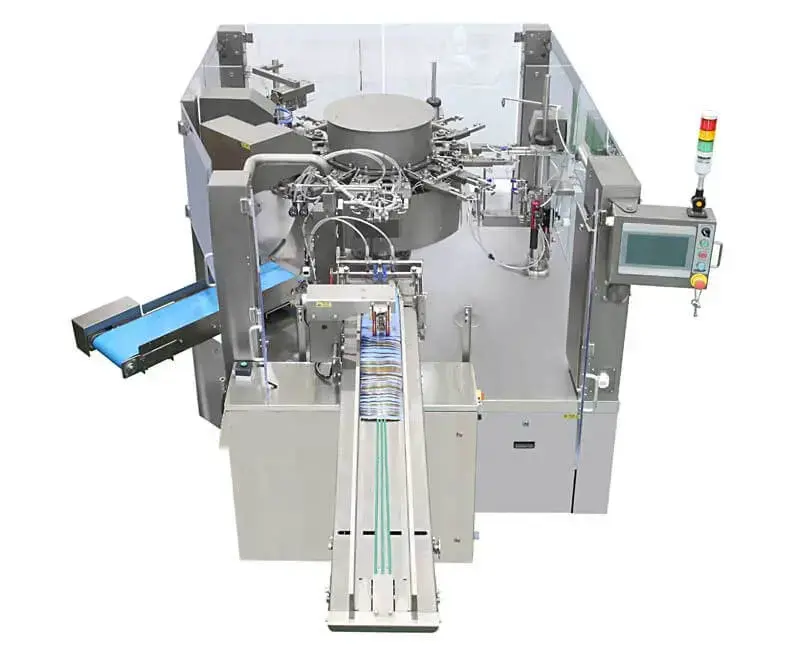

4SC-235

Premade Pouch | Simplex

With its compact design and ease of use, the Viking 4SC-235 premade pouch machine simplifies packaging, especially for those new to packaging automation.

8SG-200A

Premade Pouch | Simplex

The Viking-8SG-200A automatic rotary premade pouch filler and two-step sealer is ideal for packaging powders and food products into bags from 100mm–200mm.

8S-235

Premade Pouch | Simplex

Our most popular simplex premade pouch filler and sealer, the Viking 8S-235 handles bags up to 235mm at speeds up to 60 BPM — including Standcap Pouch pouches.

8S-285

Premade Pouch | Simplex

The Viking-8S-285 automatic rotary premade pouch machine is ideal for packaging powders and food products into bags ranging from 130mm–285mm wide.

8S-320

Premade Pouch | Simplex

The Viking 8S-320 8-station single bag automatic rotary premade pouch machine fills and seals powders and food products in bags up to 350mm wide at up to 50 BPM.

8S-450

Premade Pouch | Simplex

The Viking-8S-450 automatic rotary premade pouch machine fills and seals powders and food products in bags up to 500mm wide, at speeds up to 40 BPM.

8SD-135

Premade Pouch | Duplex

Customized to your requirements, the rapid 8-station, dual bag Viking-8SD-135 automatic rotary premade pouch machine quickly fills and seals bags at up to 100 BPM.

10S-235

Premade Pouch | Simplex

The Viking-10S-235 10-station automatic rotary premade pouch filler and sealer is ideal for packaging applications that require extra fillers and options.

8SD-165

Premade Pouch | Duplex

The Viking-8SD-165 automatic rotary premade pouch machine fills and seals bags up to 165mm wide, at speeds up to 100 BPM, increasing throughput and quality.

7SU-240

Premade Pouch | Duplex

The Viking-7SU-240 2-lane automatic rotary premade pouch machine fills and seals bags up to 240mm wide, at speeds up to 80 BPM for applications in any industry.

8SU-180

Premade Pouch | Duplex

The Viking 8SU-180 automatic rotary premade pouch machine bags powders, liquids, and food products in bags up to 180 mm wide, at speeds up to 80 BPM.

8SU-240

Premade Pouch | Duplex

The Viking-8SU-240 2-lane automatic rotary premade pouch machine fills and seals bags up to 240mm wide, at speeds up to 80 BPM for applications in any industry.

8SQ-135

Premade Pouch | Quadruplex

The Viking 8SQ-135 4-lane automatic rotary premade pouch machine fills and seals 4 bags at one time on its 2 rotary tables, for speeds of up to 200 BPM.

8SQ-285

Premade Pouch | Quadruplex

The Viking 8SQ-285 4-lane automatic rotary premade pouch machine has 2 rotary tables on a single platform to fill and seal 2 bags at once, at up to 100 BPM.

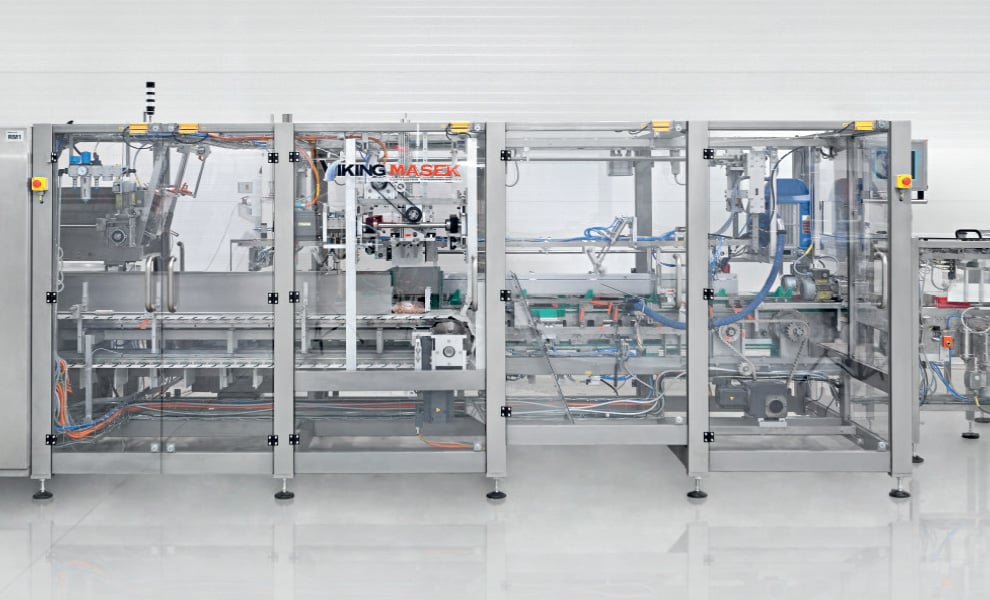

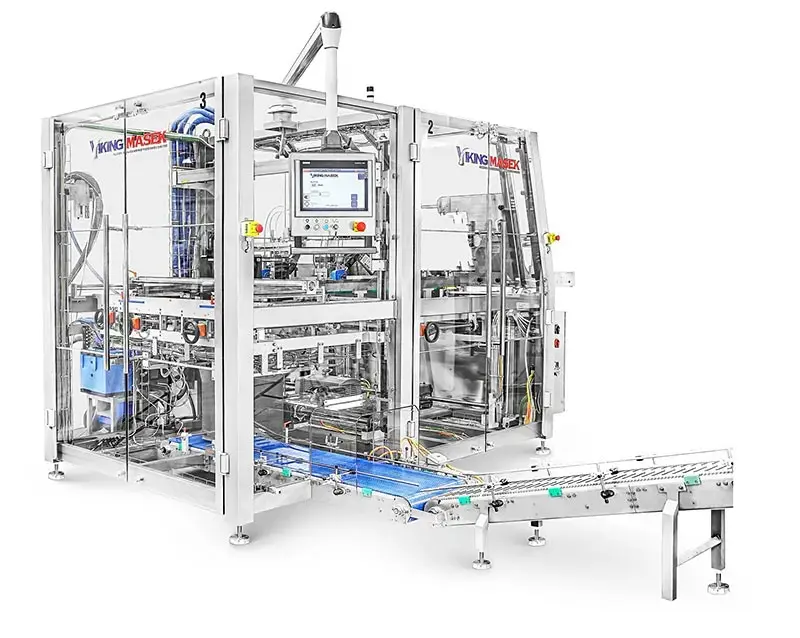

CAM-C

Cartoning & End-of-Line Automation

Looking for versatility and ease of use in a continuous endload cartoner? You've found it in the compact, flexible, and rugged CAM-C. Learn more.

CAM-I

Cartoning & End-of-Line Automation

Discover the many benefits of the CAM-I intermittent endload cartoner: compact design, simple changeovers, various closure systems, and custom feeders.

CAM-S

Cartoning & End-of-Line Automation

Our family of CAM-S sleeve cartoning equipment is designed to your requirements — ideal for packaging ready meals, salads, and other jars and cans.

CAM-W

Cartoning & End-of-Line Automation

Servo-driven, stainless steel intermittent motion packaging solution quickly erects, loads, and closes wraparound cartons using hot glue.

CFM

Cartoning & End-of-Line Automation

Top load carton assembler and filler handles different carton shapes in single, double, or triple head operation.

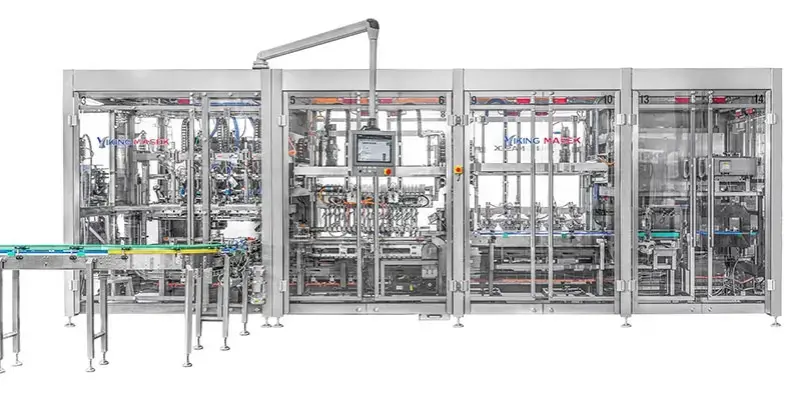

CLM

Cartoning & End-of-Line Automation

Versatile, high-performance top load cartoners runs different carton shapes in single, double, or triple head operation.

CFM-T

Cartoning & End-of-Line Automation

Versatile, high-performance tray cartoner with state-of-the-art tray forming technology can run different tray shapes in single head operation.

MFM

Cartoning & End-of-Line Automation

Multifunctional topload MFM combines carton erector, product loading unit, and carton closing machine into one compact unit to maximize floor space.

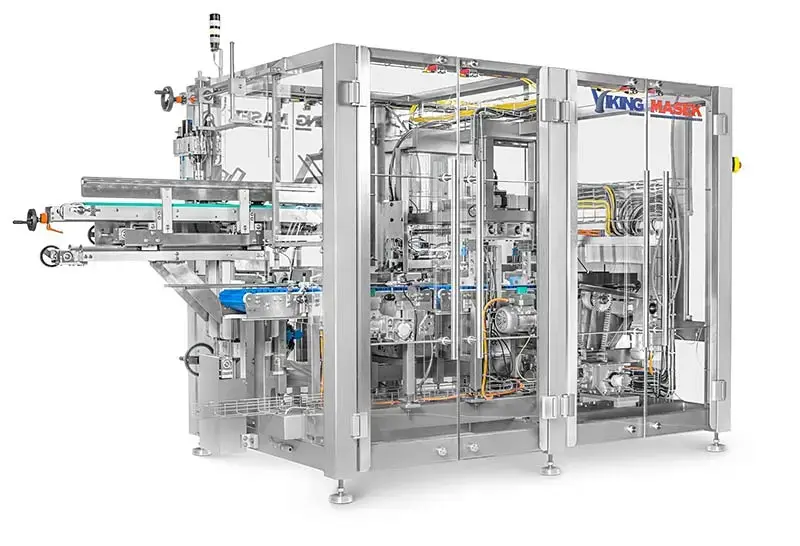

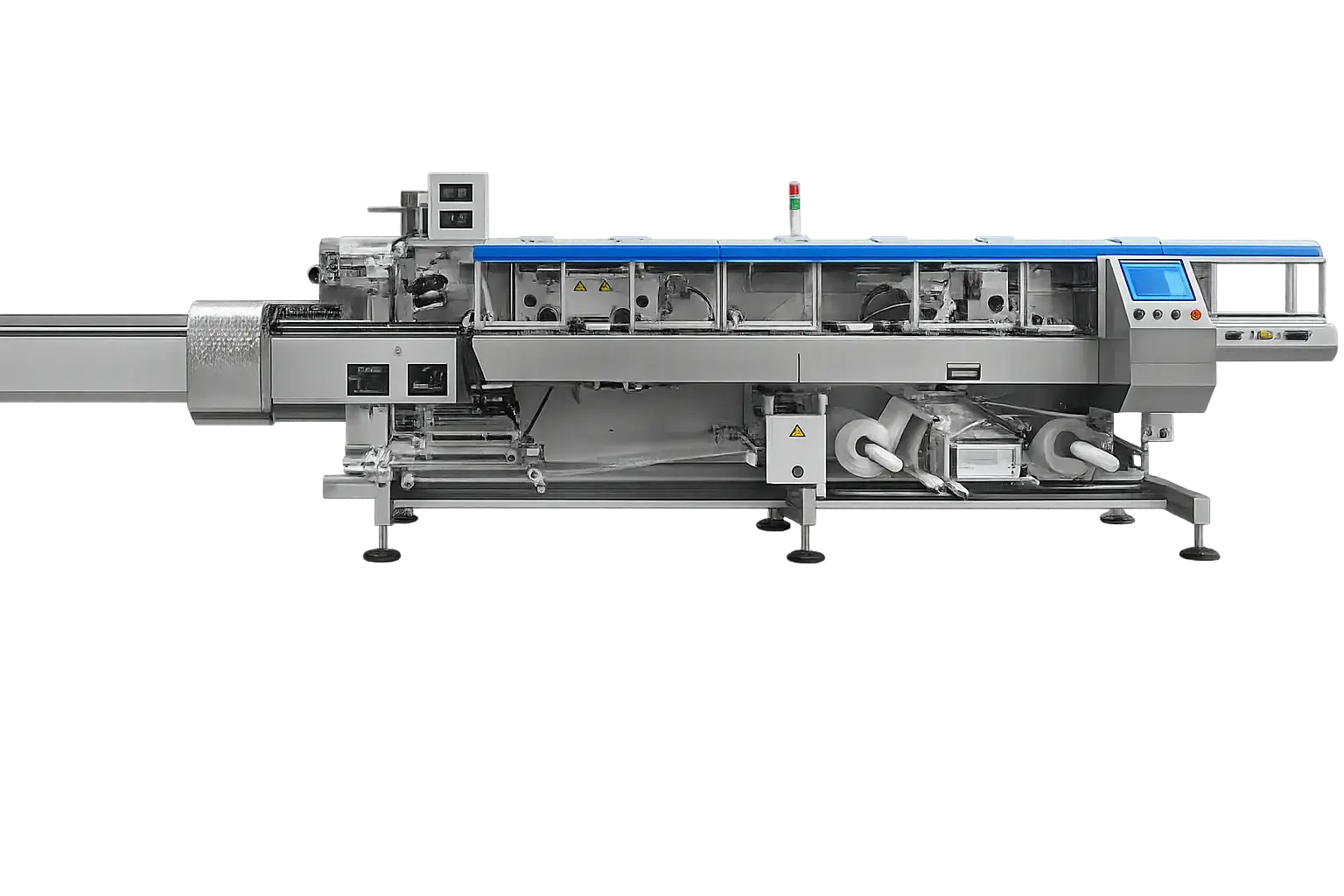

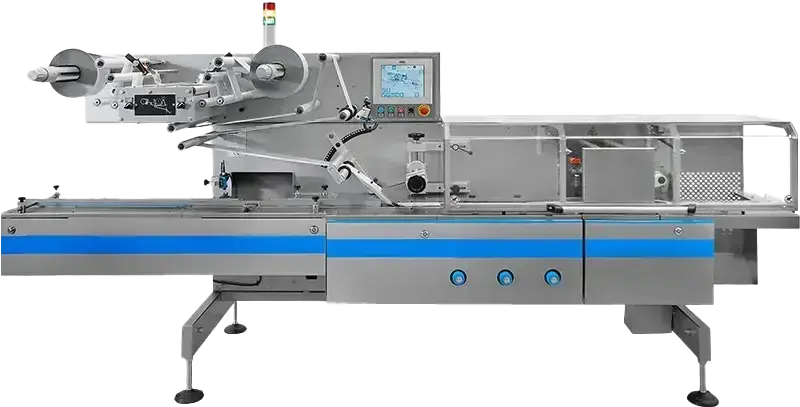

FW-30

Flow Wrapper | Horizontal Flow Wrapper

FW-30 horizontal flow wrappers with top-and-bottom film reel holders offer efficient 4- side-seal packaging of low profile products at up to 200 bpm.

FW-300

Flow Wrapper | Horizontal Flow Wrapper

The FW 300 horizontal flow wrapper provides versatile multi-format packaging up to 500 bpm with flexible film options and fast, servo-driven changeovers.

FW-60

Flow Wrapper | Horizontal Flow Wrapper

The FW-60 horizontal flow wrapper offers flexible automation, clean seals, and speeds up to 200 bpm to package delicate, irregular, or hard to handle products.

FW-600

Flow Wrapper | Horizontal Flow Wrapper

The FW-600 horizontal flow wrapper packages delicate, sticky, or irregular products with bottom film feed, easy, reliable changeovers, and speeds up to 500 bpm.

FW-90

Flow Wrapper | Horizontal Flow Wrapper

The servo-driven FW-90 horizontal flow wrapper packages standard products with flexible feeding options, quick format changeovers, and speeds up to 200 bpm.

FW-900

Flow Wrapper | Horizontal Flow Wrapper

The FW-900 horizontal flow wrapper packages standard products at speeds up to 500 bpm, with servo-driven precision, format flexibility, and easy changeovers.

FW-9000

Flow Wrapper | Horizontal Flow Wrapper

The FW-9000 horizontal flow wrapper with automatic feeding, quick changeovers, and compact reliability provides multi-format production at up to 1000 bpm.

HFS: Handling Feeding Systems

Flow Wrapper | Flow Wrapper Feeder

Our PAF, SAF, and RAF Handling Feeding Systems (HFS) efficiently group, assemble, and feed your products for optimal flow wrapping.

CFS: Conveyor Feeding Systems

Flow Wrapper | Flow Wrapper Feeder

Our RDS, POS, and DSS Conveyor Feeding Systems (CFS) handle high volume lines, align disordered products, and synchronize speeds for various product types.

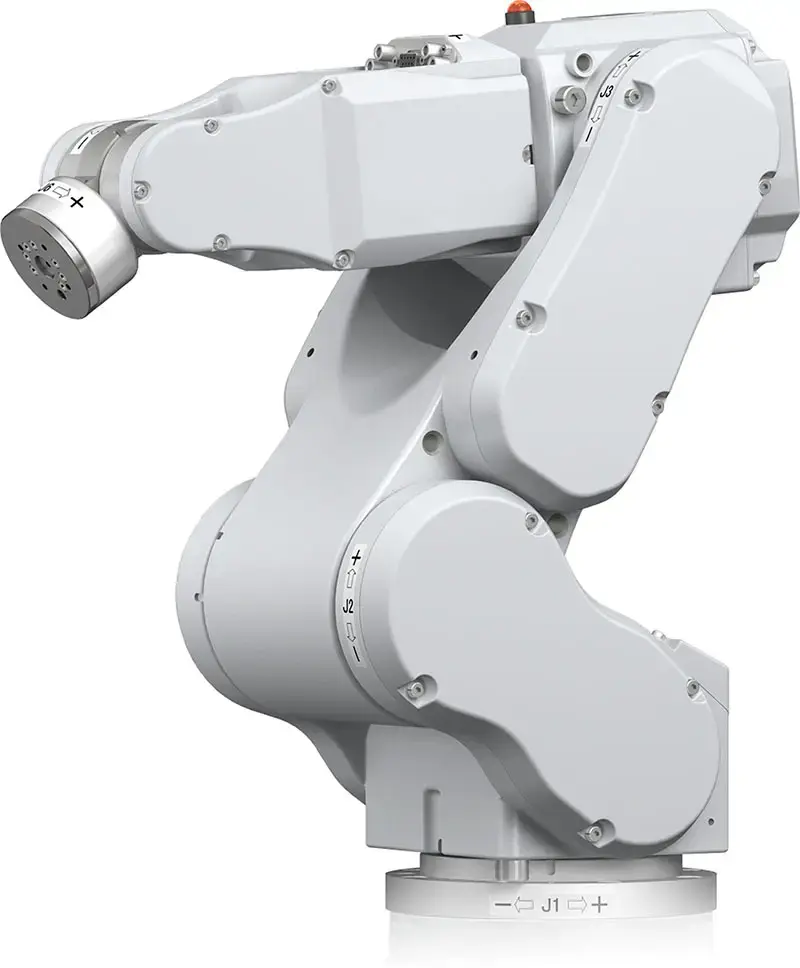

RFS: Robot Feeding Systems

Flow Wrapper | Flow Wrapper Feeder

Boost production efficiency with our Robot Feeding Systems (rFS): ANTrO, SCArA, DELTA, COBOT & CArTE robotics handle diverse product types with precision.

How Can

We Help?

Explore packaging solutions, connect with the Viking Masek team, and get your questions answered any time.