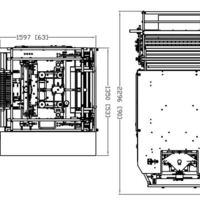

VFFS Packaging Machine for Liquids and Dusty Products

The M250’s rugged construction and enclosed jaw drive makes this VFFS bag-maker an excellent choice for packaging in dusty or wet environments.

Features

- Robust stainless steel frame

- Enclosed, direct drive jaw actuation

- Siemens or Allen Bradley control

- Off-the-shelf components

- Minimal maintenance requirements

- Short film path

- Small machine footprint

- No tool change-over

- Self-centering pull belts

- Automatic film tracking

- VFD powered film unwind

- Quick film splice table

- Product stagers

- End-seal cooling air

- Bag deflators

- Photo-eye and encoder

- Tri-fold guard door

- Jaw obstruction detection

- Runs most film structures

- Storage for 100 product recipes

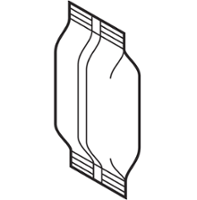

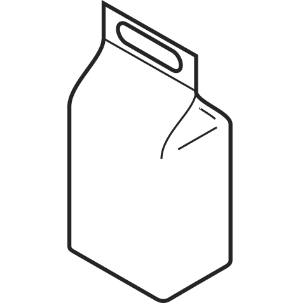

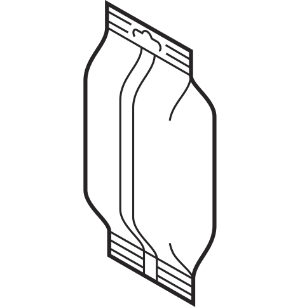

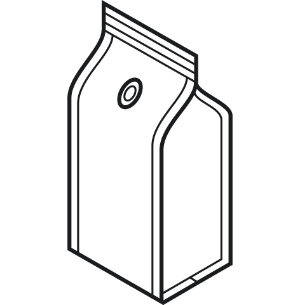

Featuring an enclosed jaw drive and a rugged stainless steel frame, the VFFS M250 is the best packaging machine for coffee, cereal, cannabis, and other dusty products. This versatile piece of equipment is one of the few vertical form fill seal machines capable of packaging liquids as well as solids. Stainless steel, durable construction lets the M250 package in the harshest dusty and wet environments. Optional washdown construction allows cleaning the machine to stringent food quality regulations.

Videos

How to Package Nuts Video

Here is a total packaging solution for almonds that packages at speeds of 49-50 bpm.

A gravity feed buggy hopper lifts and deposits bulk nuts onto a pneumatic slide which leads to a multi-head scale, where the nuts are weighed to 16 oz fills and dropped into a VFFS M250.

A zipper applicator and metal detector are also part of the system. After being formed, filled, and sealed, the finished packages are transported on an indexing conveyor.

Options

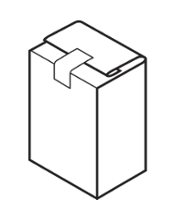

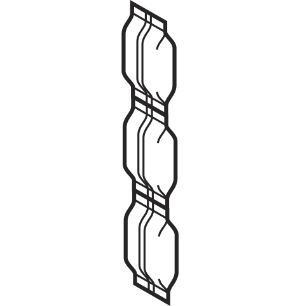

- Bag-in-bag configuration

- Flat bottom bag assembly

- Horizontal jaw for up to 340 mm (13.39") wide bag

- Impulse sealing for poly film structures

- Washdown IP66 construction

- Vacuum pull belts

- Hole punch (Euro slot or round)

- Fold-down/tape-down unit

- Load shelf

- Product settler

- Gas flush

- Static elimination

- Degassing valve applicator

- Tear notch

- Remote diagnostics

- In-feed and take-away conveyors

- Zipper applicator

- Integration with variety of fillers, printers, metal detectors, label applicators, and checkweighers

Specifications

- Maximum Roll Diameter: 500 mm (19.6")

- Maximum Roll Width: 545 mm (21.4")

- Weight: 750 kg (1,655 lbs)

- Air Requirements: 6 bar (15-18 CFM at 90 PSI)

- Power Supply: 6 kVA (480 V, three phase, 60 Hz., 20 AMPS)