Freeze-Dried Products Hot in Premium Pet Food Market

Consumers love their pets and are increasingly concerned with their diets. Premium pet foods that use fresh, raw, whole, organic, and functional ingredients have taken the industry by storm. The days of walking into the store and throwing a 50 lb paper sack of kibble into the cart are waning; in 2016 increasingly discerning and informed pet owners are purchasing their pet's food in more compact packages, filled with premium, nutritionally-dense food. The latest trend seeing enormous recent growth in the premium pet food market is treating Fluffy and Fido to a freeze-dried dinner.

Consumers love their pets and are increasingly concerned with their diets. Premium pet foods that use fresh, raw, whole, organic, and functional ingredients have taken the industry by storm. The days of walking into the store and throwing a 50 lb paper sack of kibble into the cart are waning; in 2016 increasingly discerning and informed pet owners are purchasing their pet's food in more compact packages, filled with premium, nutritionally-dense food. The latest trend seeing enormous recent growth in the premium pet food market is treating Fluffy and Fido to a freeze-dried dinner.

A Brief History of Freeze-Drying

Developed during World War II for use on the battlefield, freeze-drying is a process by which products (such as food) can be preserved without requiring refrigeration or damaging of organic material. According to How Products Are Made, freeze-drying food has many advantages. Because up to 98% of the water content has been removed, the product is extremely lightweight and much easier and less costly to ship. Freeze-dried food is also relatively contamination-risk-free as the dehydration process makes it almost impossible for bacteria to survive. Lastly, because the physical structure of the organic product is not altered, freeze-dried foods retain their original color and shape, making them much more attractive to consumers than foods preserved by other methods.

Freeze-Drying Captures the Premium Pet Food Market

For many years human food commodities like meat, fruits, vegetables, beans, and coffee have been freeze dried for our convenience. These foods are shelf stable and can be shipped to remote areas of the world where refrigeration is not available. Like many other human food trends, freeze-drying has made it's way to the pet food market.

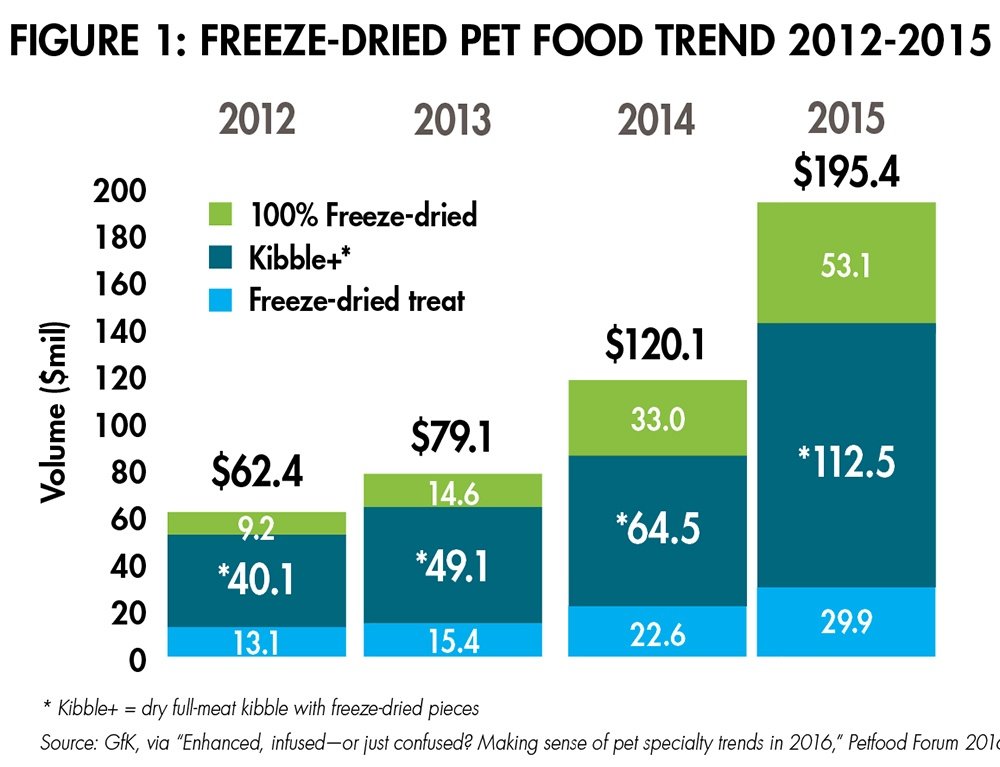

With the increase in demand for premium pet foods, freeze-dried food for pets continues to grow year over year. Pet Food Industry magazine reports that in 2015, the total freeze-dried segment grew 62.7% year-over-year, bringing in $195.4 million. In January and February 2016 alone, the freeze-dried category brought in $38.2 million. If that remains the average for the rest of the year, the category will see 17% growth by the end of 2016.

Proper Packaging Critical for Freeze-Dried Pet Foods

How Products Are Made explains that freeze-dried foods must be sealed in airtight packages to prevent the foods from absorbing moisture in the air. Flexible packaging offers superior barriers against air moisture, oxidating gases, and contamination, while also being portable and offering conveniences like zipper reclosures.

Flexible packaging is only as good as the weakest component, which often can be the package seals. Improperly designed or calibrated packaging machinery will not provide a strong, reliable, repeatable seal, and that can spell disaster for freeze-dried pet food products that rely on airtight pouches. Packaging machine sealing jaws that are forged from multiple pieces of metal can fail to heat evenly, causing improper seals and eventually, warping of the jaw that necessitates shortcuts like shimming to work properly. Viking Masek's pet food packaging machines are built with sealing jaws forged from one solid piece of metal, allowing for the perfect seal, every time.

Some of the latest freeze-dried pet foods also require modified atmosphere packaging, known as gas or nitrogen flush. This process injects nitrogen into the pouch before sealing to displace air and prevent oxidation and spoilage of food. This helps increase the shelf life of pet food, allowing for greater distribution.