To Shim or Not to Shim?

Production demands never cease and the pressure to keep a machine running 24/7 is intense!

When Quality Control stops production for poor quality seals or bags not meeting specifications, machine operators go into panic mode...

Brian: "Slow the machine down and see if we can make good bags."

Eric: "Turn up the temperature, that'll get us sealing again."

Mike: "More jaw force, that's the only way we'll meet our shift quota!"

When these adjustments fail, one "sure-fire fix" is to shim the jaws in order to make them come into compliance (mate correctly) when sealing the bag. While this may work in the short-term, shimming jaws is not a long-term solution.

Shimming is generally overcoming one of two typical problems:

- Jaws are not set up correctly

- Jaws are wearing prematurely or warping

If your operators are shimming jaws in order to meet quality standards, you need to find the root cause before doing damage to the machine or compromising product quality.

Jaws Not Set Up Correctly

Before running production, sealing jaws should be brought to compliance. Compliance means the jaws should be parallel, square, and mesh together as designed to create a quality seal. If you are getting good seals on one side of your bag and weak seals on the other, your jaws are probably out of alignment. A quick fix many operators use when under production deadlines is to shim the jaw to compensate for the weak seal side.

What if the shim falls into a bag during production?

Shimming jaws is a band-aid: It doesn't fix the root cause of the problem. Shims also create a potential product safety hazard: What if the metal or plastic falls out during production and into a bag of product? Scheduled preventive maintenance and proper set ups will help keep sealing jaws square and true.

Jaw compliance should be checked:

- Before machine start up

- After a material jam

- After size changes

- After major maintenance or upgrades

If your operators have been through multiple setup attempts and you still can't bring the jaws to compliance, then it is time to check for warping or premature failure.

Jaws Wearing Prematurely or Warping

If you have been running production for several months and suddenly can't make a good seal—even after going through an entire jaw set up procedure—then your jaws may be wearing out or becoming warped. In order to check if jaws are warped they have to be removed from the machine and placed on a flat, machined surface.

Safety Warning: If the jaws are heated, make certain they cool completely before removing.

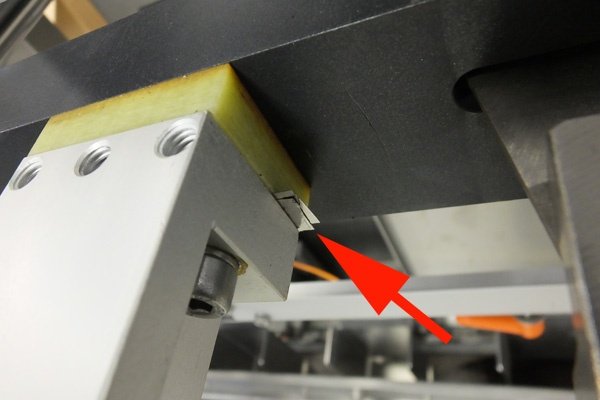

Once removed from the machine, lay the jaws on a flat surface and bring the patterned sides of the jaws together. The patterns should mesh along the entire length of the jaws. Also place a level across the jaws to check for misalignment. If your jaws don't align on a flat surface out of the machine, they will never create a good seal in the machine at production speeds.

Jaws alignment is critical: Notice how the pattern meshes together to create a quality seal.

Quality jaws should last a long time and not wear out under normal production conditions. If your jaws are starting to warp, contact your OEM. At Viking Masek we use Teflon-coated jaws forged from one solid piece of high-alloy steel—our jaws rarely, if ever fail.