Flexible Packaging and Sustainability: Consumer Driven Innovation

According to the Flexible Packaging Association (FPA), sustainable packaging "takes into consideration all aspects of the triple bottom line (financial, social, and environmental) and each stage of a package's life cycle." With the tremendous growth of values-driven packaging and increased consumer demands for eco-conscious practices, an industry that has in the past gained notoriety for its potential impact on the environment has been working hard to innovate and transform itself into a desirable alternative to rigid packaging.

There's no question that the trend toward green and sustainable packaging is here to stay, and it's growing at an ever increasing rate. Consumers demand more of companies today in the way of social responsibility, eco-friendly values, and sustainable business practices. Whether it be energy efficient machinery, compostable packaging films, reusing and upcycling of materials, or maintaining the freshness and integrity of natural and organic products from farm to table, the packaging industry has responded to these demands with increased fervor.

While there is no denying that product packaging of any kind has an impact on the environment, flexible packaging has made great progress in reducing its environmental impact. Let's look at how:

Smaller carbon foot print. According to the FPA, one single truckload of unfilled flexible pouches is the equivalent of 26 truckloads of unfilled glass bottles. Lighter, lower density flexible packaging results in more being transported for less; not only reducing carbon emissions but reducing the cost to companies and consumers.

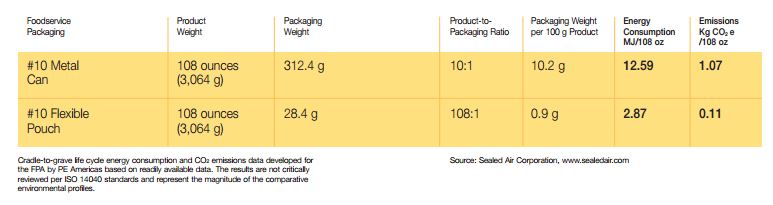

Less energy consumption. In foodservice, metal cans have been the standard for many years as a convenient, safe way to store and transport bulk food items. With the advent of flexible packaging, it has quickly been revealed how energy inefficient these cans are. According to an FPA case study, the flexible pouch consumes 75% less energy than a metal can, and generates 1/10 the carbon dioxide emissions.

Uses fewer resources. The FPA reports that it takes only 1.5 pounds of flexible packaging to package 60 pounds of beverage, while 3 pounds of aluminum and a whopping 50 pounds of glass are required to packaged the same amount of beverage. Reducing raw materials reduces energy and carbon emissions expended to transform those raw materials into packaging.

Results in a higher product to package ratio. Flexible packaging is just that - flexible. It can better mold to and be formed, filled, and sealed to best fit its product, resulting in less wasted space and more efficient use of packaging. By mass alone, flexible packaging outperforms its alternatives when considering how much weight it adds to the product.

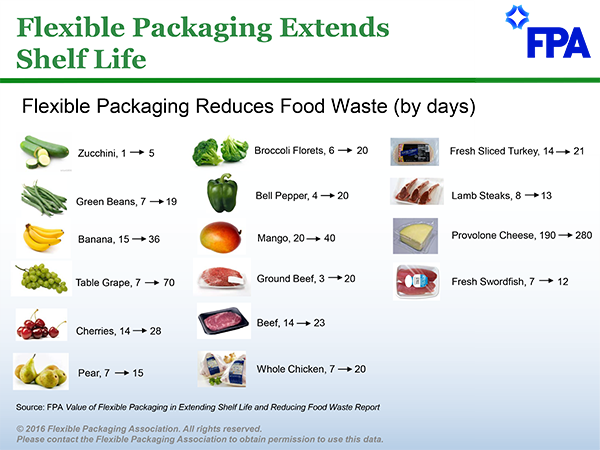

Reduces food waste. Packaging serves an important function in the food industry: It keeps its contents fresher, longer, sometimes by weeks! In areas where access to refrigeration or convenience shopping is limited, this can greatly increase food reach and security and decrease illness caused by contamination or spoilage.

Reduces food waste. Packaging serves an important function in the food industry: It keeps its contents fresher, longer, sometimes by weeks! In areas where access to refrigeration or convenience shopping is limited, this can greatly increase food reach and security and decrease illness caused by contamination or spoilage.

Uses recyclable, degradable, or reusable materials. According to recent data from PMMI, the market for global green packaging is forecast to reach $275.15 billion by 2020. This demand has caused film producers to innovate in that direction. From compostable or recyclable pouches to packaging meant for reuse, the flexible packaging materials industry is listening.

PMMI reports that "food packaging led the global green packaging market with a share of 54% in 2015." Is your business poised to keep up with the trend toward values-driven packaging practices? Overwhelmed with the choices available to you? Let us help! Stop by our booth at a trade show near you and chat with industry experts in sustainable packaging: