Choosing the Best Materials and Methods for Packaging Machinery

When searching for packaging machinery, only the best will do. Machinery for your business is more than an initial investment. It can make or break the future of your company. Therefore you want to choose packaging machinery constructed of the highest quality materials. Whether you are interested in upgrading outdated machinery or expanding an existing production line, use this guide to help you make the right choice in equipment.

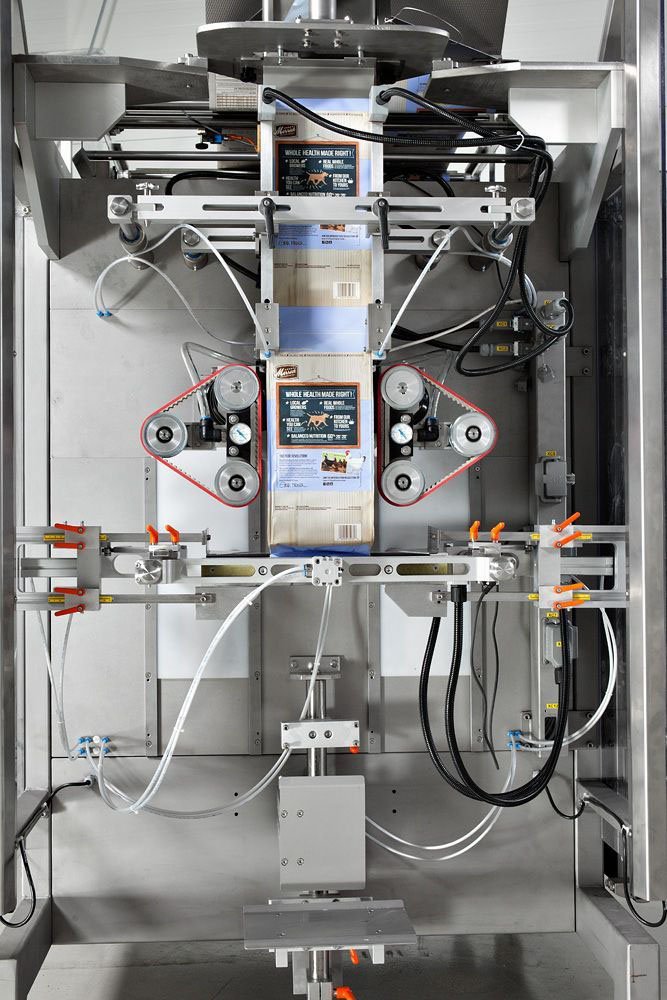

Stainless Steel

Stainless steel is commonly used to make machine components, including the frame, product contact surfaces, and in cases of sanitary machinery, the entire piece of equipment. This material is selected for its durability and strength. Stainless steel also benefits packaging equipment by its increased corrosion- and oxidation resistance. In other words, stainless steel does not rust as easily as other metals. It withstands high-pressure cleaning, liquids, dust, humidity, and other moisture-introducing elements. It is for all the preceding reasons that when choosing a material for packaging machinery construction, stainless steel is the top choice in most instances.

Anodized Aluminum

When it comes to pull belt pulleys utilized in packaging machinery, there is one metal that stands out from the crowd. Aluminum as a metal is prized for its light weight and super strength. Additionally, it is the most commonly used nonferrous metal. If you are looking for a metal that is eco-friendly, thanks to its abundance in the earth's crust, aluminum is the least likely to be over-mined.

When it comes to pull belt pulleys utilized in packaging machinery, there is one metal that stands out from the crowd. Aluminum as a metal is prized for its light weight and super strength. Additionally, it is the most commonly used nonferrous metal. If you are looking for a metal that is eco-friendly, thanks to its abundance in the earth's crust, aluminum is the least likely to be over-mined.

When aluminum is anodized for packaging machinery parts, its strength is increased tremendously. According to the Aluminum Anodizers Council, "the purpose of anodizing is to form a layer of aluminum oxide that will protect the aluminum beneath it. The aluminum oxide layer has much higher corrosion and abrasion resistance than aluminum." For this reason, anodized aluminum is ideal when used for pull belt pulleys in a piece of packaging machinery. In sum, pulleys made from anodized aluminum will deteriorate at a much slower rate than pulleys made from other materials like plastic.

Simplification of Parts

One of the best ways to ensure that custom-made packaging machinery is going to last is by simplifying its parts and ensuring they are modular and non-proprietary. Contrary to sometimes popular belief, when it comes to packaging equipment, simpler is almost always better. As more parts and complexity are built into a machine, this increases the chances of small issues becoming magnified when problems arise. Additionally, by choosing stronger materials such as aluminum and steel for parts, machine components will need replacing less often.

Now that you know what to look for in packaging machinery, you are ready to start shopping for your next piece of equipment. Browse our website to check out what we have to offer in terms of customizable, simple, and durable packaging machinery. Contact us to set up a consultation or to find out more about the best materials to look for in packaging machinery.