Thinking Outside of the Box: Flexible Packaging Takes Hold

Yes, we know it's an over-used phrase. But 'thinking outside the box' in the packaging world is quite literal: Many top companies are complementing their product line with or completely switching to flexible packaging instead of rigid boxes, jars, cans, and bottles. Why the change?

Yes, we know it's an over-used phrase. But 'thinking outside the box' in the packaging world is quite literal: Many top companies are complementing their product line with or completely switching to flexible packaging instead of rigid boxes, jars, cans, and bottles. Why the change?

1. Cost

Despite all the rhetoric otherwise, many changes in packaging come down to one main issue: Money. Saving it, that is. According to the Flexible Packaging Association's Brand Owner Study, 49% of brand owner respondents who increased use of flexible packaging cited production cost as a reason for the shift. Other cost savings reported include:

- Supply chain efficiencies and lower costs of transportation

- An increase in product sales

- Improved competitive positioning

- Ability to price their product at a premium

- Less costly to automate with packaging equipment

Numbers often speak the loudest, especially when it comes to a company's bottom line.

2. Shipping & Storage

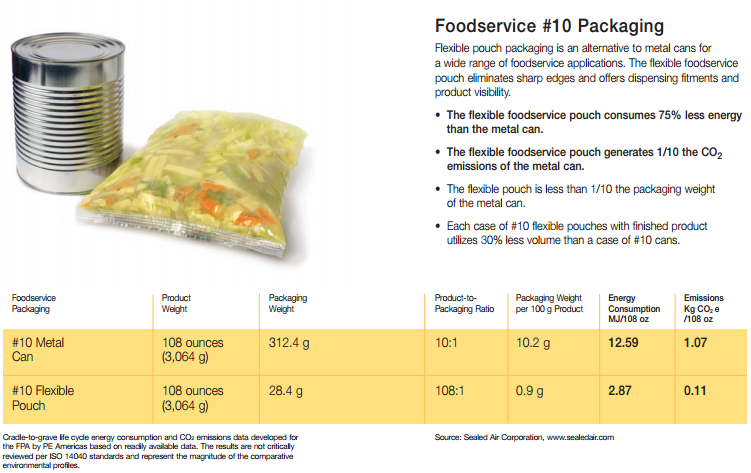

Items are shipped by weight. The heavier the shipment is, the more it will cost. This issue becomes even more important when companies are shipping thousands of pounds of product a day. Rigid packaging can weigh as much as 10 times more than flexible pouches, leading to crippling shipping costs. By mass alone, flexible packaging outperforms its alternatives when considering how much weight it adds to the product.

When products are being stored, displayed, or case-packed, rigid packaging is limiting. It is not malleable, meaning any empty space inside the package is wasted from an efficiency standpoint. Flexible pouches, on the other hand, can better contour to the product and adjust to differing pressures and storage requirements.

3. Sustainability & Environment

Flexible packaging has a smaller carbon footprint than its rigid counterpart. According to data compiled by the FPA, overall, flexible pouches consume 75% less energy than metal cans. Carbon dioxide emissions generated from fabrication, shipment, and disposal of flexible pouches can be 1/10 the emissions than that of the metal can.

The metal and glass from rigid containers are readily recyclable, and for many years flexible packaging lagged behind in the area of how to responsibly deal with end-of-life-cycle waste. Many flexible packaging materials today can be recycled and composted, and there are more and more innovations on this front every day.

4. Marketing

Let's face it: When you are browsing crowded store shelves, you are inundated with choices. Brands that market their product with attention-grabbing, communicative packaging win the game. That can be difficult to achieve with the limited visible area on rounded containers like jars and cans.

From a visual standpoint, a can, jar, or bottle obscures valuable surface area that could be used for marketing. Flexible pouches offer increased opportunity for branding and labeling. Flexible packages can also be hung on peg hooks or stand unassisted, acting as their own billboard.

5. Consumer Appeal

According to the FPA's Flexible Packaging Transition Advantages Study, 71% of consumers prefer flexible packaging overall. For many reasons, top among them:

- Ability to reseal the package

- Ease of storage

- Easy, tool-free opening of package

- Ease of transport (carry handles)

- Portion control

- Sustainability

- Safety (shatterproof, no sharp edges)

A flexible package, to many consumers, also infers a quality, gourmet product, while rigid packaging like cans speak to economy and mass production. The Millennial consumer group is especially attracted to products that will set them apart; products that look like they didn't just come off an assembly line. Flexible packaging, especially the popular stand-up pouch (Doypack), satisfies those desires.

Have questions about premade pouch packaging equipment? Get answers in our eBook: 10 Questions to Ask when Considering Premade Pouch Machines: