E-Commerce Growing in Pet Industry, Pet Food Packaging Adapts

Convenience is king. Consumers today can have groceries delivered to their front doorstep, schedule household essentials to ship on a predetermined schedule, and can be introduced to new products via monthly deliveries based on personal preferences. It only goes to follow that consumers are now purchasing pet food for their furry friends online as well. The days of lugging enormous bags of kibble through the store are over; now we can have pet food products delivered to our homes with the click of a button. As the shopping habits of pet parents change, so must pet food packaging to keep up with the latest trends in consumer behavior.

Convenience is king. Consumers today can have groceries delivered to their front doorstep, schedule household essentials to ship on a predetermined schedule, and can be introduced to new products via monthly deliveries based on personal preferences. It only goes to follow that consumers are now purchasing pet food for their furry friends online as well. The days of lugging enormous bags of kibble through the store are over; now we can have pet food products delivered to our homes with the click of a button. As the shopping habits of pet parents change, so must pet food packaging to keep up with the latest trends in consumer behavior.

Online Pet Food Sales Outpace Growth of Total Pet Retail

According to Pet Food Industry Magazine, "between 2010 and 2014 pet care e-commerce in the US grew by 76%. In contrast, the American Pet Products Association (APPA) reported 20% growth for the total pet product industry over the same time frame." Over 80% of this growth has been seen in mass online distributors like Amazon.com and Chewy.com, especially in subscription-based services. Pet Food Industry Magazine continues: "Both Chewy and Amazon saw their subscription sales of pet food nearly triple year-over-year in the first quarter of 2016." The subscription model has already made an impact on how consumers shop for groceries, so it follows that it is also impacting how they shop for their pets.

Pet Food Packaging Must Adapt to Consumer Desires

As consumers gravitate toward convenience in how and where they acquire their pet's food and treats, they seek convenience in packaging as well. This means rigid packaging like metal cans are less in demand than in the past. That's not to say that rigid metal cans don't have their applications in the pet food industry, but this packaging format is decreasing in use for many reasons, a few of which are illustrated below.

|

|

| Flexible Pet Food Packaging (Bags, pouches) | Rigid Pet Food Packaging (Cans, bottles) |

| Do not require special tools to open | Often require can openers or other tools to open |

| Often feature resealable options like press to close zippers | Often cannot be resealed |

| Do not contain sharp edges | Sharp metal edges can pose a safety threat |

| Uses less resources to produce and has a smaller carbon footprint | Uses more resources to produce and has a larger carbon footprint |

| Can adapt to fit its product, resulting in less wasted space | Is rigid and unadaptable to its product |

| Lightweight flexible packaging decreases shipping costs | Heavier rigid packaging increases shipping costs |

| Has ample surface area on which to print clear labels, directions, and ingredients | Cans are often small and labels, directions, and ingredients difficult to read |

Flexible Pet Food Packaging Machinery Satisfies Consumer and Manufacturer Demands

Today's consumer demands pet food products that are conveniently packaged and easily available online. This means two things for pet food manufacturers: They must provide packaging options that satisfy their consumer's demand for convenience and be able to supply and ship their products on short notice. If their pet food products are sold through a third party, this intermediary often will use a derivative of Just-in-Time inventory to keep their costs low. This means that suppliers must be able to ship their products to the third party distributor on even shorter notice.

Flexible pet food packaging equipment can achieve these two goals with ease. Not only can this machinery integrate with many different types of product fillers, conveyors, easy open and reclosable options, and cartoning and case packing solutions, but it provides predictability in packaging that makes managing the supply chain much easier for a pet food company that wishes to offer its products to the online market.

Pet Food Packaging Equipment Options

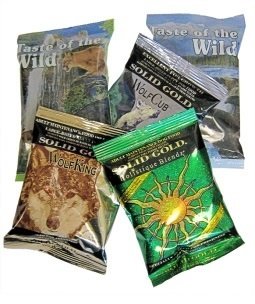

There are many options on the market for flexible pet food packaging equipment. A popular vertical form fill seal (VFFS) packaging solution for pet food is Viking Masek's M series, namely the VFFS M250 and M400. Viking client Diamond Pet Foods utilizes an M250 to package their pet food products and raves about how easy it is to use and how reliably it runs. This particular model offers the ultimate in flexibility for pet food manufacturers that need to package multiple skus and sizes of products with its easy tool-less changeover.

Another popular packaging solution for pet food and treats is Viking's Rotary Premade Pouch Machine. Different from VFFS equipment, this machine fills and seals custom premade pouches. This bag type has been very popular in the pet food industry because of its convenience and ability to differentiate a product from its competition. The premade pouch machine for pet food can also accommodate different products and offers simple changeovers for the ultimate in low-stress on-demand pet food packaging.