Flexible Packaging Machine Spotlight: Rotary Premade Pouch Machine

For many years, Viking has offered rugged vertical form, fill, and seal (VFFS) packaging equipment. VFFS machinery vertically forms rollstock film into bags, fills the pouches with product, and lastly, seals the bags shut. Recently Viking has expanded its product offering to a different kind of innovative packaging technology: Machinery that fills and seals premade pouches. No rollstock required, our Rotary Premade Pouch Machine efficiently packages product into attractive premade bags that are as unique as your product. This bag type has exploded in popularity for its ability to differentiate a product from its competition on the shelf while providing a great canvas for product marketing. A cost-effective alternative to rigid packaging, the premade pouch provides convenience and flexibility both to the manufacturer and end consumer.

What Sets Viking's Premade Pouch Machine Apart

While competitors also offer machinery that fills and seals premade pouches, Viking's Rotary Premade Pouch equipment sets itself apart. Unlike our competitors, we weren't satisfied with simple, standard mechanical drives on our premade pouch machines. We've developed proprietary technologies that use the latest Allen Bradley components and servo drives to improve performance and increase output by as much as 50%.

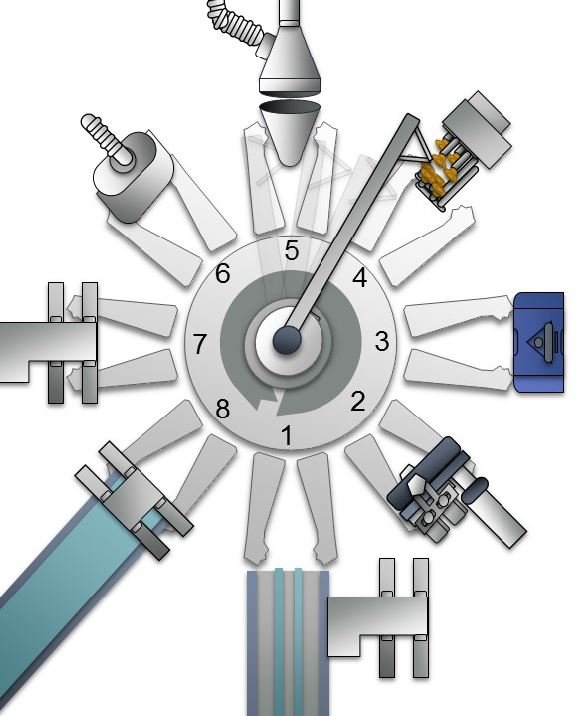

Built to last, this machinery boasts a space-saving rotary design, with different bag size parameters and rotary configurations available, as well as a single or dual pouch system set-up. Most popular are models Viking-8S-235 and Viking-8S-285. Let's walk through how product is packaged on one of these innovative machines with a video followed by descriptions of each step of the process:

1. Bag Feeding & Pouch Gripping

The Rotary Premade Pouch Machine offers three different types of bag feeding:

- Linear belt: For zippered bags, larger pouches, or miscellaneous bag types

- Stand up: For thin bags, pouches that are already filled, or pouches with tin tie

- Stacking: For rectangular shaped bags only; must be side sealing pouches

The Premade Pouch Machine will then grip and pick up bags from the bag feeder. These grippers are engineered for up to 10 kg grip strength. This grip maintains strength over time so there is no sagging in the middle of the bag even after increased weight is added.

2. Zipper Opening

In preparation for product filling, the zipper on the bag needs to be opened. An accessible zipper is recommended, or the bags may be filled from the bottom of the pouch if the zipper is enclosed and cannot be opened without compromising the package.

3. Printing

Print lot numbers or use by dates at this station. An inkjet printer is recommended, however, if a thermal transfer printer is preferred by the customer, the printing must be done after the top of the pouch is open. Embossing is also available here.

4. Pouch Opening/Detection

Vacuum suction secures the bag at this point in the cycle. Forks open the pouch while suction keeps the bag on rotation. Sensors at the bottom of the bag confirm the presence of the pouch. If the sensor does not detect a bag, the pouch will not fill and will remain on rotation until it is sensed.

5. Product Filling

The pouch is now ready to be filled with your product. When dispensing non-liquid product from an auger, scale, or cup filler the product is filled with a funnel. If the product is liquid, it is dispensed with a nozzle.

6. Options (Based upon application)

For powder products like flour, a dust collection hood option can be added. For solid products, a vibratory settler can be added. For liquid products, a secondary filling station can be added. Gas flush (more about this below) and oxygen scavenger insertion can also be added as options. Additional items are available based on your application.

7. Heat Sealing/Deflation

The Premade Pouch Machine creates a superior seal beginning with heat sealing, the first step in its two-step sealing system. Air deflators are located at the sealing station as well.

8. Seal Cooling/Discharge

The second step of the sealing system consists of cooling bars to create a strong seal on the pouch. At this point, the filled and sealed pouch is discharged from the machine. The entire rotary packaging process can produce between 40 and 200 filled pouches per minute depending upon model and configuration chosen as well as product application.

Industries Served by the Rotary Premade Pouch Machine

Pet Food

While premade pouches are quickly gaining popularity in all industries, we have seen them dominate the pet food industry as of late. Here's why:

- Many consumers consider their pets to be part of their family. As such, healthier and specially formulated pet food products are increasing in popularity. This is especially true with the natural and organic food trend; we desire the same quality of food for our furry family members. Keeping these often preservative-free products fresh from farm to Fido is of utmost importance. Viking's Premade Pouch machinery creates a strong seal with its two-step sealing process, ensuring your pet's favorite snacks go unspoiled.

- Pet food companies are transitioning away from bulk multi-wall paper packaging to more compact flexible packaging, often choosing premade pouches with zippers. This transition away from paper packaging has many benefits, among them greater portability and convenience for the consumer, and less product loss for the manufacturer because of the superior barrier and seal created with premade flexible pouches.

- With the pet food market growing more competitive by the day, a new product needs to stand out. The most important piece of a product differentiation strategy is what the consumer notices first: The packaging. Long gone are the days when the only options were canned food or 20-pound sacks of kibble. Consumers now look for stand up premade pouches, which are custom created to broadcast the manufacturer's marketing in graphics and print.

Natural and Organic Food Products

Another popular industry for the Rotary Premade Pouch Machine is natural and organic food products. Special care needs to be taken to make sure these products remain fresh but also retain strong shelf appeal. Here's how Premade Pouch machinery works for this industry:

- Sustainability and environmentally friendly packaging is very important in this market. Company philosophies and causes have extended all the way to packaging, giving rise to values-driven packaging initiatives. Compostable and sustainable premade pouches and long-lasting, efficient sustainable machinery like the Rotary Premade Pouch machine is demanded in this market.

- With worldwide recalls of food products in the news, cleaning and sanitation has become even more important in packaging, especially when your products come straight from the farm with little to no processing. IP65, IP66, and IP67 washdown construction is available on our Premade Pouch machines, allowing for superior cleaning ability, thereby decreasing the risk of bacterial exposure or cross-contamination.

- Modified atmosphere packaging is an option with our Premade Pouch machinery. This technology flushes the package with a precise mixture of atmospheric gases prior to filling and sealing to displace oxygen, thereby reducing oxidation and inhibiting bacterial growth. This increases a natural or organic product's shelf life and helps the product retain its attractive color and texture.

The options available to you in packaging technologies today can be overwhelming. Let Viking use our expertise to take that weight off your shoulders. Request a free packaging equipment consultation today.