Should you invest in automated coffee packaging equipment?

Today just about everything can be automated in a coffee roasting operation, not least of all the packaging of your products. But is coffee packaging equipment the right choice for your particular business? In this post, we look at the related opportunities and challenges in an effort to help you make an informed decision.

Coffee Packaging Equipment: Opportunities

Increased efficiency and accuracy. Modern filling equipment like augers and multi-head scales can fill coffee packages to a high degree of accuracy. This means less product wastage resulting from overfilled packages and a more efficient overall coffee packaging process.

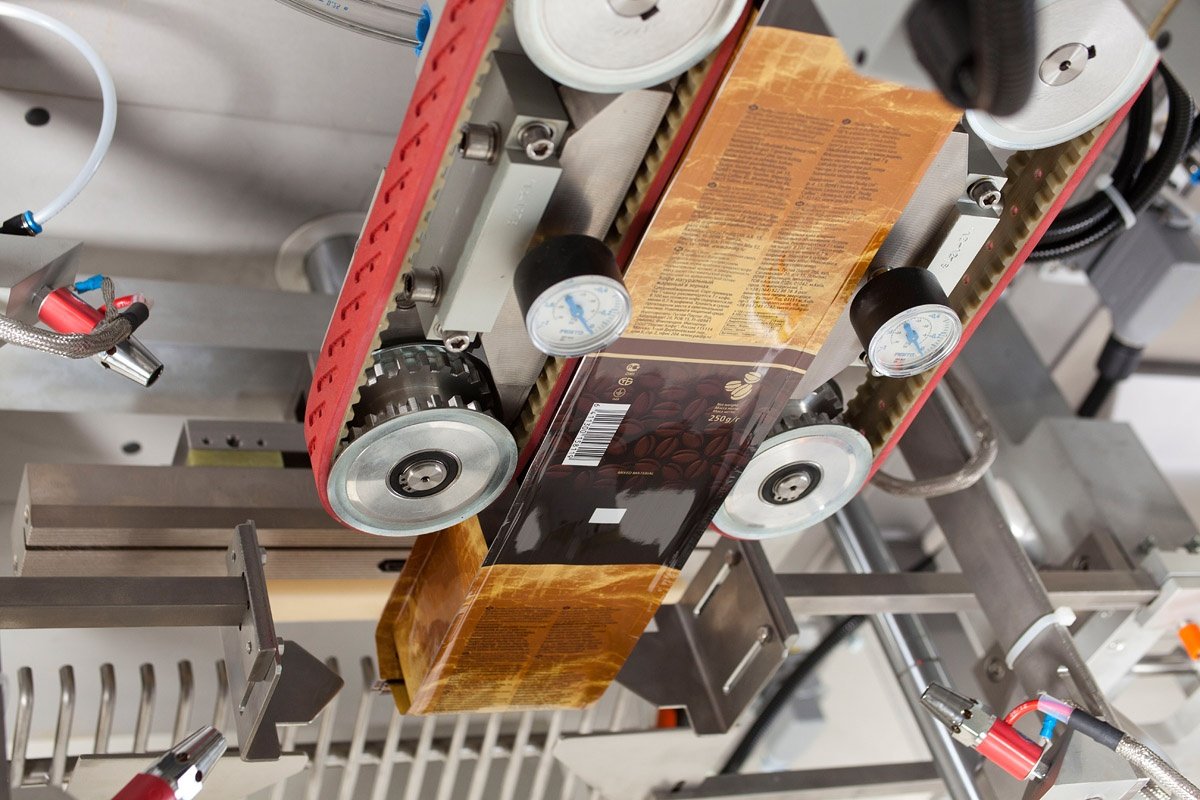

Superior package seal integrity. When packaging manually, often package sealing can be hard to get exactly right every single time. Coffee packaging equipment takes all guesswork out of the sealing process by following pre-programmed specifications, which results in less rework and a perfect seal, every time. Superior seal integrity also means less risk of exposure to outside elements like oxygen, moisture, light, and temperature fluctuations which are killers of coffee freshness.

Less reliance on human labor. Let's face it: As humans, we are costly to employ and can be unreliable and inaccurate at times. Overall, the advantages to employing humans vastly outweigh the downsides. However, when it comes to the world of packaging, there are limits on the throughput, accuracy, and efficiency of human labor. When looking solely at the numbers, machines outperform humans in virtually every facet of coffee packaging.

Higher throughput. Manual packaging process are limited in speed and often can only produce between 5 and 15 completed bags per minute. Again, human labor is usually the main limiting factor here. On the flipside, some continuous motion coffee packaging equipment models can package at speeds of over 200 completed bags per minute. That's more than 3 bags per second!

Coffee Packaging Equipment: Challenges

Higher initial investment. Highly automated coffee packaging equipment features technologies that require a higher initial investment than manual packaging processes. Expect to pay in the five to six figure range for automated coffee packaging systems. As with most things, you get what you pay for. Factors like lightning-fast packaging speeds, complex bag styles, and high-accuracy filling also add to system cost.

Workforce training and compensation implications. Coffee packaging machines are more high-tech than manual processes and as such require more training to learn. This may require additional investment in the form of onsite training from your packaging OEM. Sometimes, investing in coffee packaging equipment necessitates hiring a workforce that has a higher level of technical proficiency and education. These positions usually require a higher rate of compensation than entry-level labor.

Human job loss. There is a lot of concern today with job loss and humans being replaced with machines in the workplace. Ethically, this is a divisive and polarizing issue, and we understand both sides. However, often the efficiencies and cost savings derived from replacing human labor with machine labor can enable companies to invest in retraining displaced workers and even hiring additional staff for high-value activities.

Is Coffee Packaging Equipment Right for You?

So how do you decide if automated coffee packaging equipment is right for your business? We recommended considering packaging automation if you are:

- Requiring greater flexibility to scale up production when necessary

- Experiencing exponentially increasing demand for your coffee

- Incurring increased costs related to human labor

- Desiring a longer shelf life for your coffee

- Experiencing a lot of rework or over/underfilled coffee packages

- Incurring increased costs due to outsourcing your packaging

As with any major operational overhaul, we know access to insightful information can make the process less stressful. Here are some resources that can empower you and your staff to make the best decision, specifically when considering coffee packaging equipment:

[WORKSHEET] coffee Packaging Equipment Project Planner

[CASE STUDY] Roaster Brings Packaging In-House, Reduces Costs, Adds Jobs

[CONSULTATION] Chat with a coffee packaging equipment expert

Originally published 3/10/2017, updated 5/1/2018.