Meal Kits: Packaging Challenges and Opportunities

As we reported earlier this year, the meal kit home delivery business is booming. There's something for every consumer in this industry, from vegan to gluten-free to certified kosher meals. The busy Millennial demographic has embraced this business model for its simplicity and convenience, as well as its ability to provide nutritious, home-cooked meals with none of the hassles. However, as with all new markets borne out of convenience, it does face some challenges, especially when it comes to packaging.

As we reported earlier this year, the meal kit home delivery business is booming. There's something for every consumer in this industry, from vegan to gluten-free to certified kosher meals. The busy Millennial demographic has embraced this business model for its simplicity and convenience, as well as its ability to provide nutritious, home-cooked meals with none of the hassles. However, as with all new markets borne out of convenience, it does face some challenges, especially when it comes to packaging.

More packaging = Less food waste?

One of the main concerns when it comes to meal kit packaging is that each individual ingredient must be pre-measured and packaged individually. When ingredients are purchased in bulk to make meals at home, there is less packaging to dispose of.

However, in meal kits, the simple fact that ingredients are pre-measured means much less food goes to waste. The Food Institute reports that "most of this can be attributed to the fact that if a recipe calls for one carrot or one tablespoon of butter, customers will need to purchase a much larger package than just what is needed for the recipe, possibly wasting the rest that was unused."

Meal kit delivery businesses also likely save more food earlier on in the supply chain, because, unlike grocery stores that purchase products with little insight into what will actually be sold, meal kit enterprises know exactly what ingredients they need and when, and in exact quantities. Fast Company reports that a major meal kit company reported that they threw out 5.5% of food, while grocery stores threw out 10.5%, or almost double.

On the consumer side, the same stark differences were noticed. Fast Company added that, in a survey of 2,000 customers of the same leading meal kit company, meal  kit cooks threw out 7.6% of the food they received. Based upon USDA food waste stats for similar ingredients, an estimated 23.9% of food would be wasted to create the same meal from scratch. So consumers creating the same meal otherwise wasted an estimated 3 times as much food as consumers of meal kits.

kit cooks threw out 7.6% of the food they received. Based upon USDA food waste stats for similar ingredients, an estimated 23.9% of food would be wasted to create the same meal from scratch. So consumers creating the same meal otherwise wasted an estimated 3 times as much food as consumers of meal kits.

Of course, the better option would be to reduce food waste and packaging waste...

Sustainable meal kit packaging

Sustainable packaging materials, both for ingredient packaging and shipping container packaging, is also an important concern to address when it comes to meal kit services. The Food Institute provides an example of an innovative meal kit company that devised a shipping container that has become so popular that it has begun selling them to competitors. The boxes are polyurethane cubes that contain five drawers with metal plates that maintain food temperatures as specified. Once the consumer is done using the shipping container, they ship it back prepaid. The meal kit company sanitizes the box and reuses it, for a sustainable shipping container solution.

As for packaging of individual ingredients within the meal kits, recyclable and compostable packaging has all but taken over. Because meal kit services are popular among the Millennial consumer demographic (who are already concerned with sustainability), the demand for green packaging was met head-on by savvy meal kit companies looking to corner the market.

Packaging automation for meal kits

Packaging automation for meal kits

Many key players in this rapidly growing industry also have "plans to introduce other programs to cut food waste further, such as improving demand forecasting and using new automated equipment to process food," according to Food Institute. Automated packaging equipment for meal kit ingredients provides more predictability and reliability in production, which leads to better resource planning and less waste of materials and products. Not to mention, labor savings can be reinvested in the latest technologies, sustainability directives, and the best new ingredients.

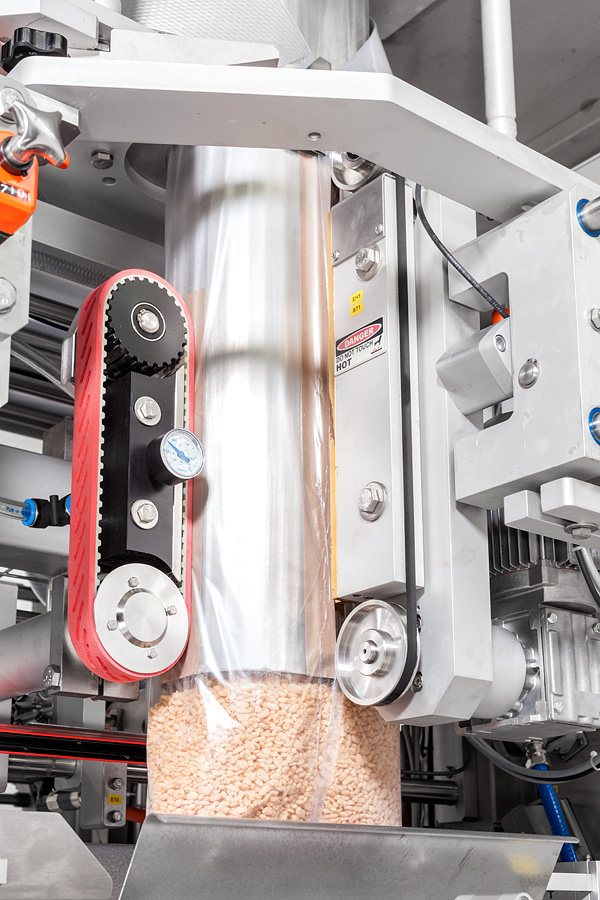

Meal kit enterprises need packaging machinery that can easily change over from one ingredient to another and can handle many different package sizes and styles. Versatile and configurable packaging equipment like Viking Masek's vertical form fill seal MS300 and MS400 are able to accommodate all VFFS bag styles as well as many different pouch sizes with their easy, tool-free changeover.

Stick packaging machinery is also popular in the meal kit industry for powder and liquid ingredients like seasonings, gravies, and sauces. Multi-lane stick packaging equipment provides efficiency and greater throughput for smaller, single-use packages. Stick pack machinery that utilizes sealing jaws forged from a single piece of material provide better seal integrity for these small packages, which leads to less ingredient spoilage, wastage, and mess during shipping.

Are you a meal kit company looking to automate packaging of some (or all) or your ingredients? We have experience creating solutions for businesses just like yours that have revolutionized their operations. Contact us for a free equipment consultation today: