The essential guide to coffee packaging machines

So you’re considering automating your coffee packaging process.

Chances are you have done some research and are a bit overwhelmed. We’re here to help you sort through the plethora of information by providing a straightforward guide to the different kinds of coffee packaging equipment, how they work, what products and bag types they can accommodate, and resources to help you take next steps. So grab a cup of coffee, this might be a long one!

Form fill seal coffee packaging machines

Machine Types

Machine Types

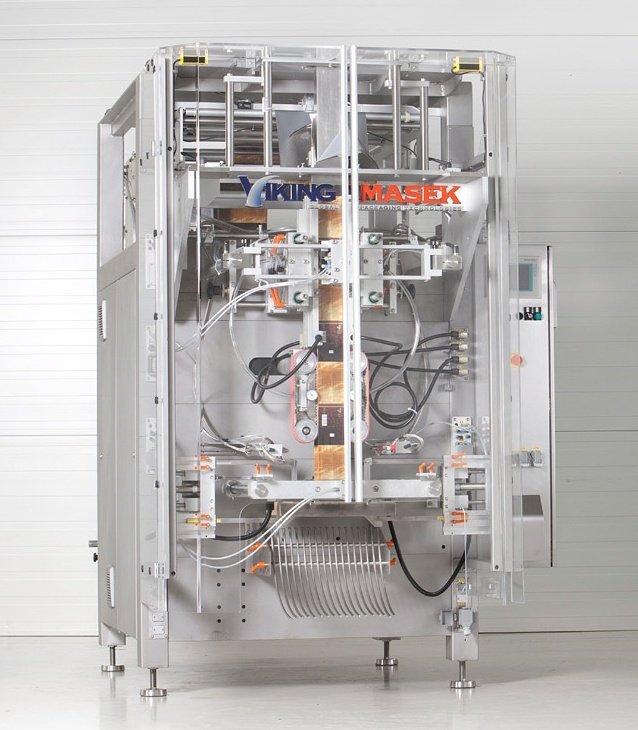

There are two main types of form fill seal coffee packaging equipment: Vertical form fill seal (VFFS) and horizontal form fill seal (HFFS). The main difference being that VFFS machines perform their operations in a vertical manner (taking up less floorspace but requiring additional height) and HFFS machines do so in a horizontal manner (taking up more floorspace with less height).

Vertical form fill seal equipment is one of the most popular and widely-used packaging machine types in the coffee industry. Here’s why:

- Lower cost to entry

- Ability to make both simple and complex bag styles

- Tried, tested, and proven technologies

- Occupies a minimal amount of floorspace

- High speeds achievable

Operation & Speeds

Basically, a VFFS coffee bagging machine uses a special former to create coffee bags from a large roll of packaging film (called rollstock), fills the newly formed bags with coffee, and seals them shut. These actions take place very quickly and sometimes simultaneously to the beat of about 30 - 300 bags per minute. Speeds are largely dependent on machine construction and your product. This is a very simplified explanation; if you are interested in the step-by-step operation of VFFS machines see our guide here.

Discrete amounts of coffee are measured and dropped into the VFFS machine by fillers like multi-head scales or augers, sometimes provided by third-party vendors. These two pieces are almost always ordered together, and most packaging equipment manufacturers offer a single-source option where they take care of quoting, ordering, and integrating all pieces into a cohesive system.

Coffee Packaging Applications

VFFS coffee bagging equipment can handle everything from whole bean to ground to instant coffee.

Coffee Bag Types

Coffee Bag Types

VFFS machines can form many different bag styles, the most popular in the coffee industry being:

- Pillow bags for fractional or single-serve packs

- Flat bottom or quad seal bags for retail or bulk packs

- Bag-in-bag style for small fractional packs sealed inside a large outer wrap

Coffee Freshness Options

There are many options available for VFFS coffee packaging systems. In high demand is Modified Atmosphere Packaging (MAP), which is standard in many industries today to preserve freshness and extend shelf life. MAP can take the form of attaching one-way valves to the film during the packaging process that will allow built-up carbon dioxide to escape the package without letting oxygen inside. Another popular MAP option is flushing the bag out with nitrogen gas prior to filling to displace oxygen. For an explanation of other MAP options see our in-depth article here.

Recommendations for Coffee Packaging

We recommend VFFS machines that feature enclosed jaw drives for the coffee industry because they protect moving internal seal jaw components from particulates and build-up that could negatively affect operation.

If speed is the name of the game and you are looking to package simple, small frac packs (pillow bags) of coffee, a high-speed continuous motion VFFS machine like the Velocity is a top choice. In early 2018, we improved our high-speed coffee packaging system from start to finish, introducing a Twin Velocity system that effectively doubles throughput with half the labor.

Another option we recommend for coffee packaging machinery is the use of vacuum pull belts. Normally, VFFS machines are equipped with friction pull belts, which use friction between the belt and rollstock to grip and transport the film through the system. However, when dealing with a dusty or oily product like coffee, particulates can impede the gripping process and decrease the lifespan of the belts. For this reason, vacuum pull belts, which use vacuum suction to grip the film for transport, are often recommended for coffee applications. Particulates will not impede film transport or cause undue belt wear when using vacuum suction.

Fill and seal coffee packaging machinery

Types

There are two main types of fill and seal equipment for coffee: Rotary and inline. Rotary automatic filling and sealing machines perform their operations in a circular fashion, requiring less floorspace as their starting point is right next to their endpoint. Inline fill and seal machines take up more floorspace as their operations take place in a straight line, with start and end points at opposite ends of the system. Rotary machines are the most popular fill and seal equipment in the coffee industry for the following reasons:

There are two main types of fill and seal equipment for coffee: Rotary and inline. Rotary automatic filling and sealing machines perform their operations in a circular fashion, requiring less floorspace as their starting point is right next to their endpoint. Inline fill and seal machines take up more floorspace as their operations take place in a straight line, with start and end points at opposite ends of the system. Rotary machines are the most popular fill and seal equipment in the coffee industry for the following reasons:

- Lower cost to entry

- Maximizes available plant floorspace

- More ergonomic design for operators

Operation & Speeds

This packaging machine type only fills and seals the bags; it does not form them. Pouches must be pre-purchased from a film supplier. Premade coffee bags are loaded into a magazine and fed into the machine where they are gripped one-by-one, opened, filled with coffee, and sealed. For a more in-depth explanation of each step in the process, see our premade pouch machine guide.

Rotary premade pouch machines are available in simplex (one-lane), duplex (two-lane), or quadruplex (four-lane) varieties. Generally, coffee companies opt for a simplex machine unless their throughput needs are higher.

Discrete amounts of coffee are measured and dropped into the pouch filling and sealing machine by fillers like multi-head scales or augers, sometimes provided by third-party vendors. These two pieces are almost always ordered together, and most packaging equipment manufacturers offer a single-source option where they take care of quoting, ordering, and integrating all pieces into a cohesive system.

Coffee Packaging Applications

Automatic pouch fill and seal machines can package all types of coffee: Whole bean, ground, and instant.

Coffee Bag Types

Coffee Bag Types

Premade pouch packing machines can fill and seal almost any type of preformed pouch. Most popular in the coffee industry are quad preformed pouches and Doy-style stand-up pouches with zippers.

If your preformed bag type is a quad seal package with a four-corner bag opening, additional design considerations and options must be added to the fill and seal machine, which will add extra cost. For this reason, many coffee producers will switch to a premade stand-up pouch with a two corner opening. If a standard quad bag is desired, a VFFS machine may be a better option as it has more flexibility at a lower cost.

Coffee Freshness Options

If Modified Atmosphere Packaging (MAP) options are desired, you can still have them on a premade pouch machine! Nitrogen flush is available, but if one-way valves are desired, the valves must be pre-applied by the film supplier.

Recommendations for Coffee Packaging

By far, we find that Viking automatic pouch filling and sealing machine models 8S-235 and 8S-285 are the most popular in the coffee market. These are single lane machines that are simple to set up and use. We highly recommend these models for growing coffee producers that are looking to take the plunge and switch from manual packaging to automation.

A dust hood placed above the filling apparatus is recommended to collect dust and particulates to reduce messes and coating of vital machine components.

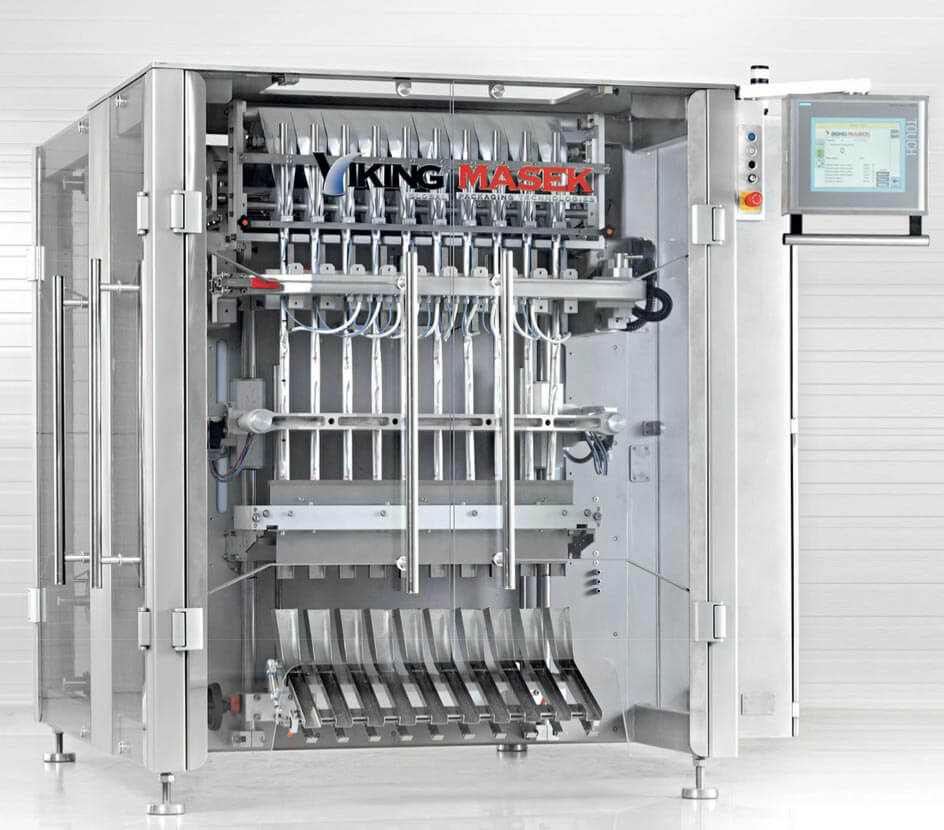

Stick pack machines for coffee packing

Types

Types

Stick pack machines are pretty standard. The main decision to make is how many lanes you require to meet your throughput needs. Anything from 2 to 20 lanes can be accommodated.

Operation & Speed

Stick pack machines operate in much the same way as vertical form fill seal equipment, with just a few differences. A large roll of packaging film is split into however many lanes the machine features, these strips are formed with small forming collars into stick packs, filled with product, and then sealed shut. For a detailed, step-by-step explanation of stick pack machine operation, see our guide here. Stick pack machines generally have a maximum speed of 80 bags per minute per lane, which is 1,200 bags per minute when using the max of 20 lanes!

Discrete amounts of coffee are measured and dropped into the stick pack machine by augers or volumetric fillers, sometimes provided by third-party vendors. These two pieces are almost always ordered together, and most packaging equipment manufacturers offer a single-source option where they take care of quoting, ordering, and integrating all pieces into a cohesive system.

Coffee Packaging Applications

Stick pack machines can accommodate ground or instant/powdered coffee. Whole beans of coffee are too large to fit through machine components.

Coffee Bag Types

Coffee Bag Types

You are limited to one main bag type: The stick pack. This can be a stick pack sealed on the top and bottom or a three-side-seal. You can opt for features like tear notches, pour spouts, chain bags, different crimp (seal) styles, and different cut types.

Coffee Freshness Options

Modified Atmosphere Packaging (MAP) options include features like gas flush. One-way valves are not an option on stick packs.

Recommendations for Coffee Packaging

If you have different stick sizes and types, you can order change kits that accommodate different packages. The machines must be stopped and parts switched out when a different bag type or size is needed.

We often recommend dust controlling options like suction nozzles and static elimination for powder coffee packaging.

Need help planning your coffee production?

How long has it been since you've assessed your coffee production and packaging processes? There may be hidden inefficiencies present that are killing your business (and your roast).

Download our free Coffee Production Planning Tool for a comprehensive check-up: